TD5 Defender Engine Crankshaft Information Page - Maintenance Tips

ENGINE

37

OVERHAUL

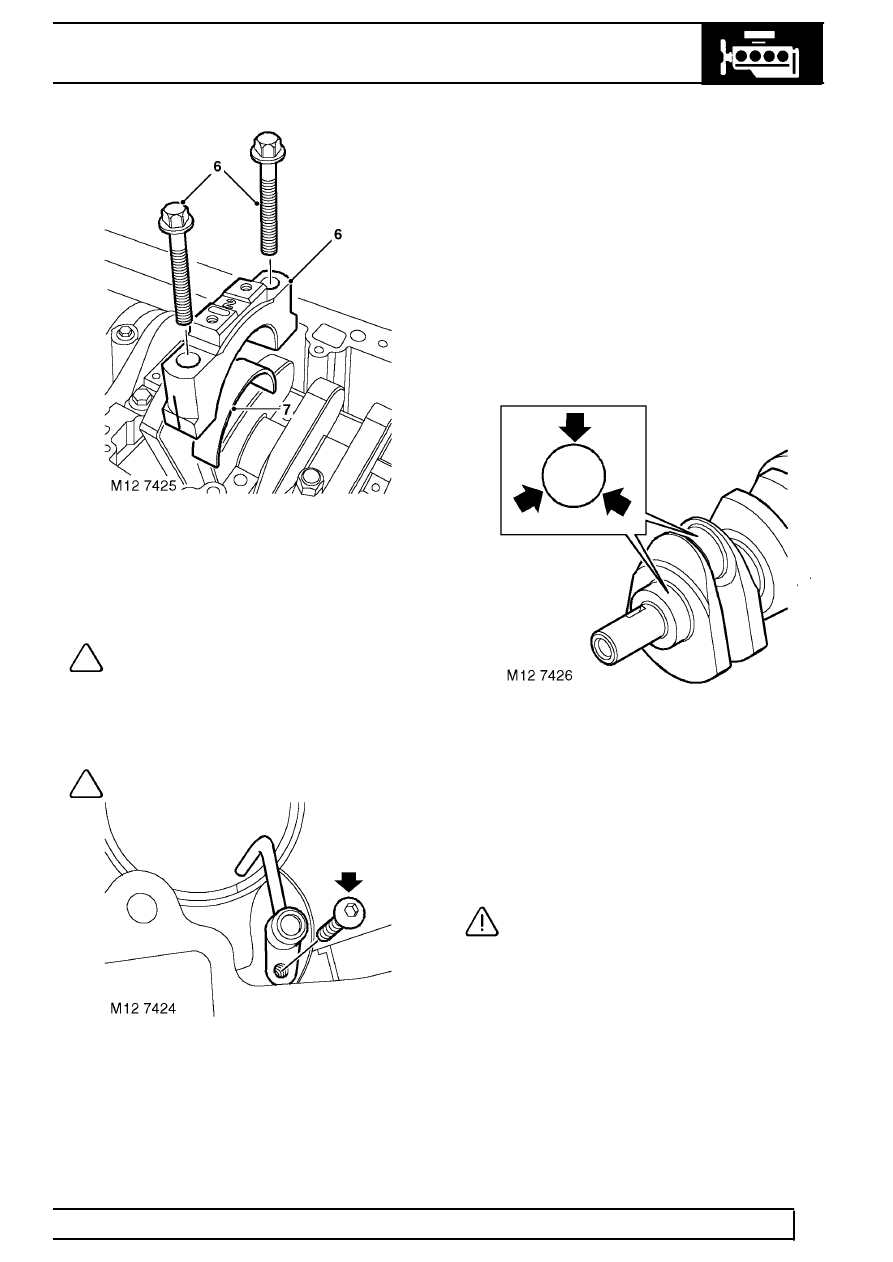

6. Fit 2 slave bolts into each main bearing cap in

turn and ease bearing caps from cylinder block.

7. Remove and discard bearing shells from each

cap.

NOTE: These bearing shells are plain.

8. Using assistance, remove crankshaft.

9. Remove and discard main bearing shells and 2

thrust washers from cylinder block.

NOTE: These bearing shells are grooved.

10. Remove Torx screw securing each oil squirt jet

to cylinder block, remove squirt jets.

Cylinder block - Inspection

1. Clean main bearing shell and thrust washer

locations in cylinder block, ensure bolt holes are

clean and dry.

2. Clean main bearing caps.

3. Clean crankshaft bearing journals, check oilways

are clear.

4. Ensure drillings in oil squirt jets are clear.

5. Check core plugs in cylinder block for corrosion

or signs of leakage, seal replacement plugs with

Loctite 243.

Crankshaft - Inspection

1. Check crankshaft main and big-end bearing

journals for scoring, wear and ovality, make 3

checks at 120

°

intervals in centre of journals.

Crankshaft bearing journal diameters:

Main bearings =

62.000 mm

±

0.013 mm (2.441 in

±

0.001 in)

Big-end bearings =

54.000

±

0.01 mm (2.125

±

0.0004in)

CAUTION: Crankshafts may not be

reground, only one size of main and

big-end bearing shell is available and if

journals are found to be scored, oval or worn,

crankshaft must be replaced. Main and big-end

bearing shells and thrust washers must be

replaced whenever they are removed.