TD5 Defender Engine Crankshaft Information and Maintenance

12

ENGINE

38

OVERHAUL

Crankshaft spigot bush

1. Check crankshaft spigot bush for wear, replace if

necessary using the following procedures:

2. Secure crankshaft in a suitably padded vice.

3. Tap a thread in spigot bush to accommodate a

suitable impulse extractor.

4. Fit impulse extractor to spigot bush.

5. Remove spigot bush.

6. Clean spigot bush recess in crankshaft.

7. Fit new spigot bush to crankshaft using a

suitable mandrel.

Crankshaft - Refit

1. Fit oil squirt jets, fit Torx screws and tighten to 8

Nm (6 lbf.ft) .

2. Lubricate new, grooved, main bearing shells with

engine oil and fit to cylinder block.

3. Lubricate new thrust washers with engine oil and

fit, grooved side facing outwards, to recess in

each side of cylinder block No. 3 main bearing.

4. Lubricate crankshaft journals with engine oil and

using assistance, position crankshaft in cylinder

block.

5. Lubricate new, plain, main bearing shells with

engine oil and fit to main bearing caps.

6. Fit main bearing caps in their original fitted

positions ensuring that reference marks are

aligned.

7. Fit and lightly tighten new main bearing cap

bolts.

CAUTION: Do not lubricate bolt threads.

8. Starting with No. 3 main bearing cap and

working outwards, tighten main bearing cap bolts

to:

Stage 1 - 33 Nm (24 lbf.ft)

Stage 2 - Further 90

°

CAUTION: Do not carry out stages 1 and 2

in one operation.

9. Check that crankshaft rotates smoothly.

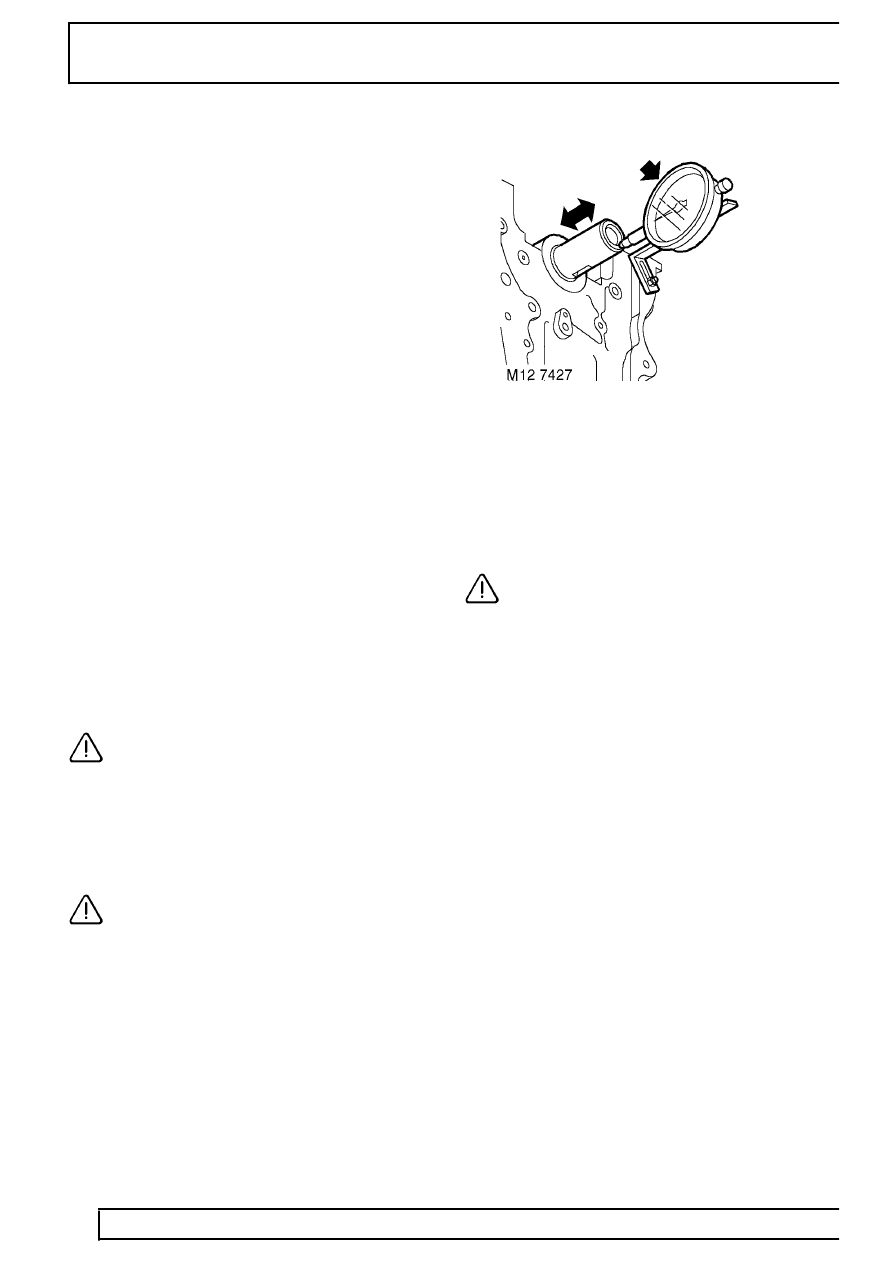

10. Assemble a magnetic base DTI to front of

cylinder block with stylus of gauge on end of

crankshaft.

11. Using suitably padded levers, move crankshaft

rearwards and zero DTI.

12. Move crankshaft forwards and note crankshaft

end-float reading on gauge.

Crankshaft end-float = 0.02 to 0.25 mm (0.001

to 0.011 in)

CAUTION: Oversize thrust washers are not

available, if end-float exceeds figure given,

crankshaft must be replaced.

13. Remove DTI.

14. Fit connecting rod bearings. See this Section.

15. Fit timing chain and sprockets. See this

Section.

16. Fit crankshaft rear oil seal. See this Section.