Discovery II

CORROSION PREVENTION AND SEALING

77-4-18 SEALING

Structural adhesive

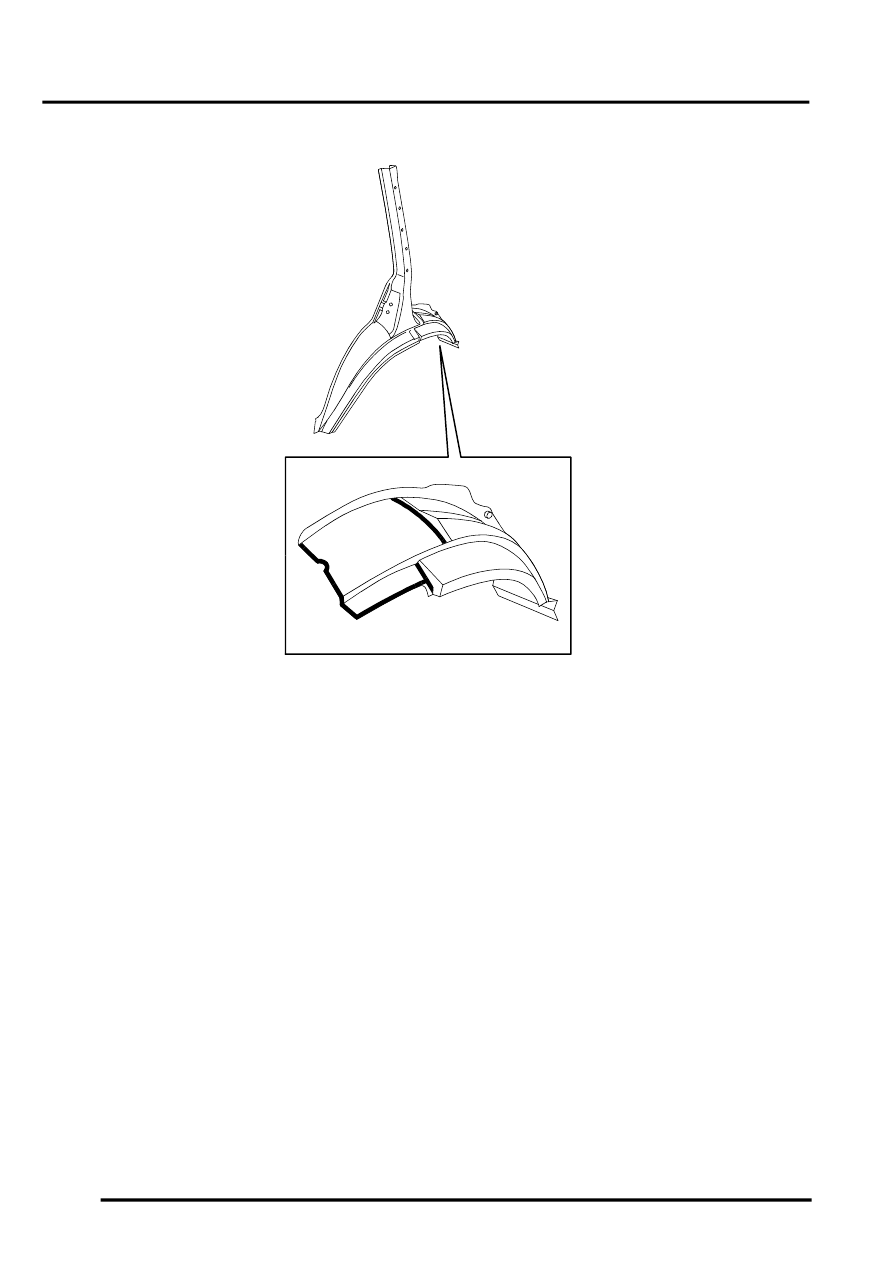

Adhesive on rear wheel arch outer assembly.

Joints symmetrically opposite to those shown are also treated. Apply 3 mm diameter beads to all joints shown.

Metal-to-metal adhesive is applied to critical joint areas during factory assembly. The material used is a high-

temperature, heat cured, nitrile phenolic which serves to bond two metal surfaces and also to seal the joint against

ingress of dust, moisture and fumes. This material is not suitable for service use and, during repair, should be

substituted by an approved Structural Adhesive.

BODY SEALING MATERIALS, MATERIALS AND APPLICATIONS, Approved materials.

Those joints which require the application of structural adhesive are detailed in the following figures. Only joints

applicable to service panels are included. Apply structural adhesive where indicated or to the mating panel surface.

CAUTION: When separating a joint treated with metal-to-metal adhesive, it is important to avoid distortion.

Heat the joint gradually until the bond weakens sufficiently to permit panel separation.

NOTE: When spot welding through metal-to-metal adhesive, take particular care to adjust the transformer setting to

ensure a reliable weld.

M77 1684A