Discovery II

ENGINE - V8

12-2-68 OVERHAUL

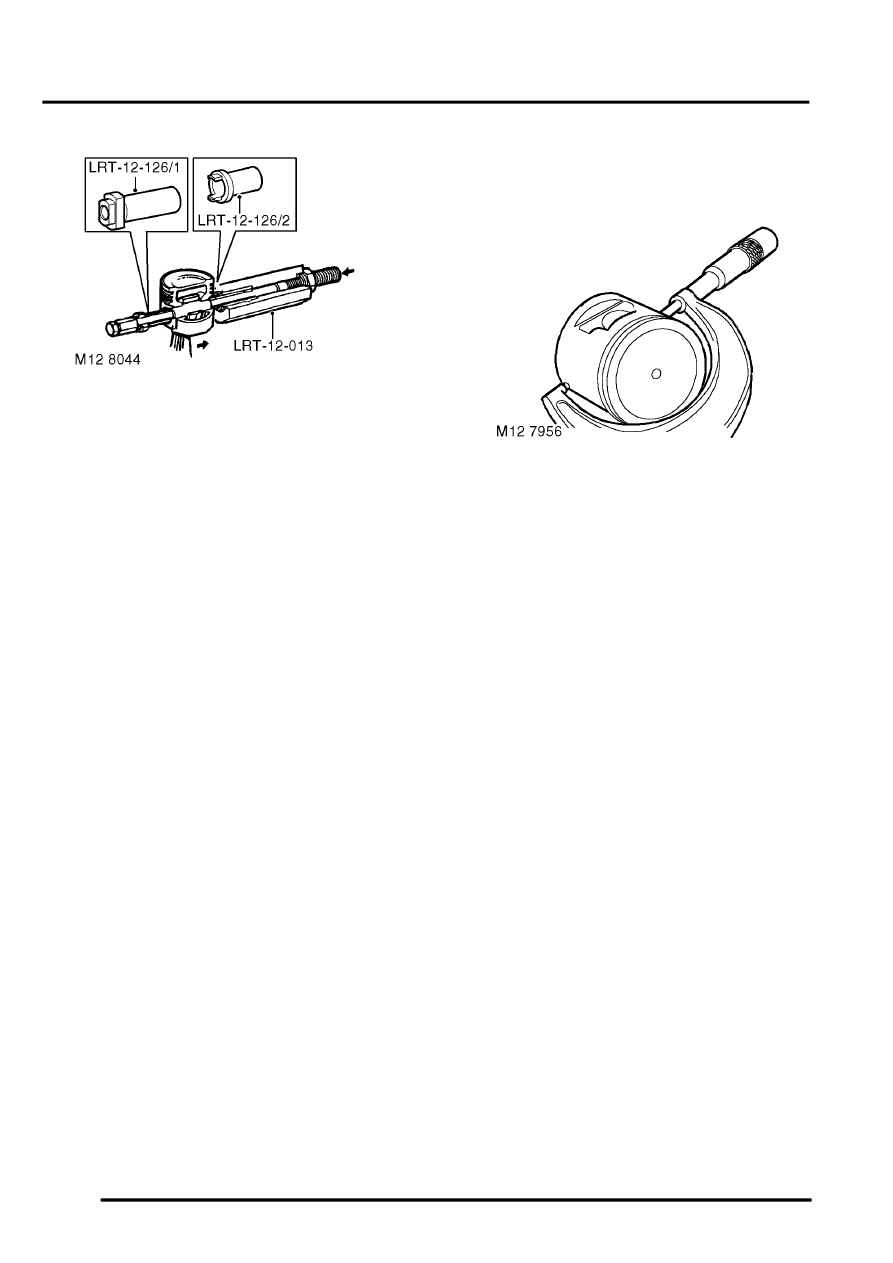

10. Position body of tool LRT-12-013 in vice.

11. Screw large nut back until flush with end of

centre screw.

12. Push centre screw forward until nut contacts

thrust race.

13. Position remover/replacer LRT-12-126/2 in

LRT-12-013 with its long spigot inside bore of

hexagon body.

14. Locate piston and connecting rod assembly on

centre screw and up to remover/replacer

adapter tool LRT-12-126/2.

CAUTION: Ensure that prongs of remover/

replacer adapter LRT-12-162/2 remain in

contact with piston and do not contact

gudgeon pin.

15. Fit remover/replacer bush LRT-12-126/1 on

centre screw with flanged end facing away from

gudgeon pin.

CAUTION: Ensure that remover/replacer

bush LRT-12-126/1 is correctly located in

gudgeon pin bore of piston.

16. Screw stop nut onto centre screw.

17. Lock the stop nut securely with the lock screw.

18. Push connecting rod to locate end of gudgeon

pin in remover/replacer adapter LRT-12-126/2.

19. Ensure remover/replacer bush LRT-12-126/1

is located in gudgeon pin bore of piston.

20. Screw large nut up to tool LRT-12-013.

21. Hold lock screw and turn large nut until

gudgeon pin is withdrawn from piston.

CAUTION: Ensure that prongs of tool LRT-

12–126/2 remain in contact with piston and

do not contact the gudgeon pin.

22. Dismantle tool LRT-12-013 and remove piston,

connecting rod and gudgeon pin.

Inspect

1. Clean carbon from piston. Inspect piston for

distortion, cracks and burning.

2. Remove piston rings from piston.

3. Measure and record piston diameter at 90

°

to

gudgeon pin axis and 10 mm (0.4 in) from

bottom of the skirt. The piston must be 0.015 to

0.045 mm (0.001 to 0.002 in) smaller than the

cylinder bore.

4. Check gudgeon pin bore in piston for signs of

wear and overheating.

5. Pistons fitted on production are graded 'A' or

'B', the grade letter is stamped on the piston

crown.

l

Piston diameter: Grade 'A' = 93.970 to

93.985 mm (3.6996 to 3.7002 in).

l

Piston diameter: Grade 'B' = 93.986 to 94.00

mm (3.7002 to 3.7007 in).

6. Worn cylinders fitted with grade 'A' pistons may

be honed to accept the grade 'B' piston

provided that specified cylinder bore and

ovality limits are maintained. Grade 'B'

pistons are supplied as service

replacements. Do not attempt to de-glaze

cylinder bores.

CAUTION: Ensure replacement pistons are

correct for the compression ratio of the

engine. The compression ratio will be found

on the cylinder block adjacent to the engine

serial number.

7. Check gudgeon pins for signs of wear and

overheating.

8. Check clearance of gudgeon pin in piston.

l

Gudgeon pin to piston clearance = 0.006 to

0.015 mm (0.0002 to 0.0006 in).