Discovery II

ENGINE - V8

OVERHAUL 12-2-51

8. Carefully remove oil seal from cylinder block to

avoid damage to seal location or running

surface on crankshaft.

Reassembly

1. Ensure both seal location and running surface

on crankshaft are clean. Ensure that bolt holes

are clean and dry.

2. Lubricate replacement oil seal with engine oil.

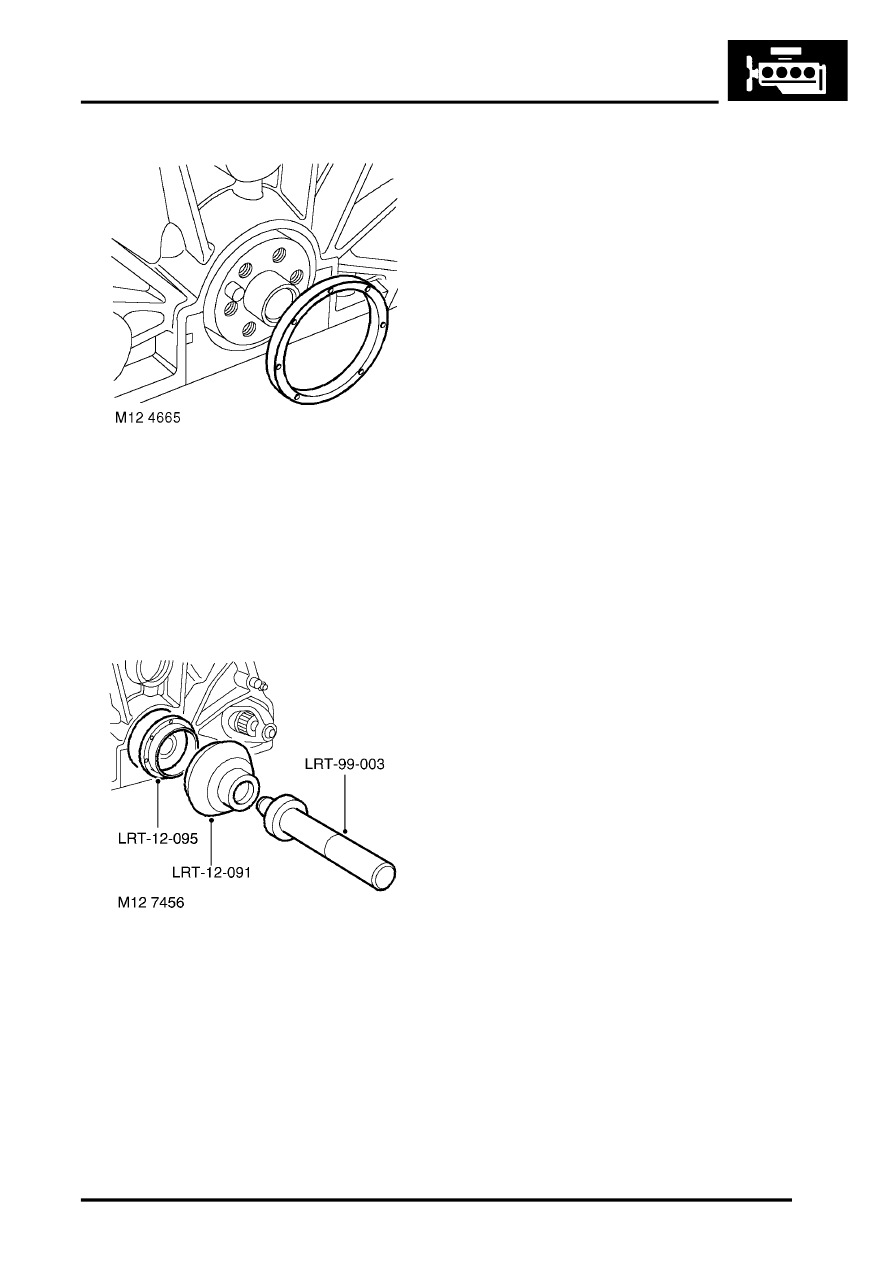

3. Lubricate seal guide LRT-12-095 with engine

oil and position to crankshaft.

4. Fit new seal squarely onto crankshaft and

remove guide LRT-12-095.

5. Fit seal into location using tools LRT-12-091

and LRT-99-003.

6. Clean mating faces of flywheel and crankshaft,

dowel and dowel hole.

7. Fit flywheel to crankshaft and, working in a

diagonal sequence, tighten bolts to 78 Nm (58

lbf.ft).

8. Fit CKP sensor.

V8, REPAIRS, Sensor - crankshaft position

(CKP).

9. Clean clutch cover, drive plate and spigot bush

in end of crankshaft.

10. Renew worn components as necessary.

11. If refitting existing drive plate, apply Molycote

FB 108 to splines.

12. Fit LRT-12-001 alignment tool to spigot bearing

in crankshaft.

13. Fit drive plate onto alignment tool, ensure side

marked 'flywheel side' is against flywheel.

14. Fit clutch cover and locate on dowels.

15. Fit clutch cover bolts and tighten in diagonal

sequence to 40 Nm (30 lbf.ft).