Discovery II

ENGINE - V8

REPAIRS 12-2-15

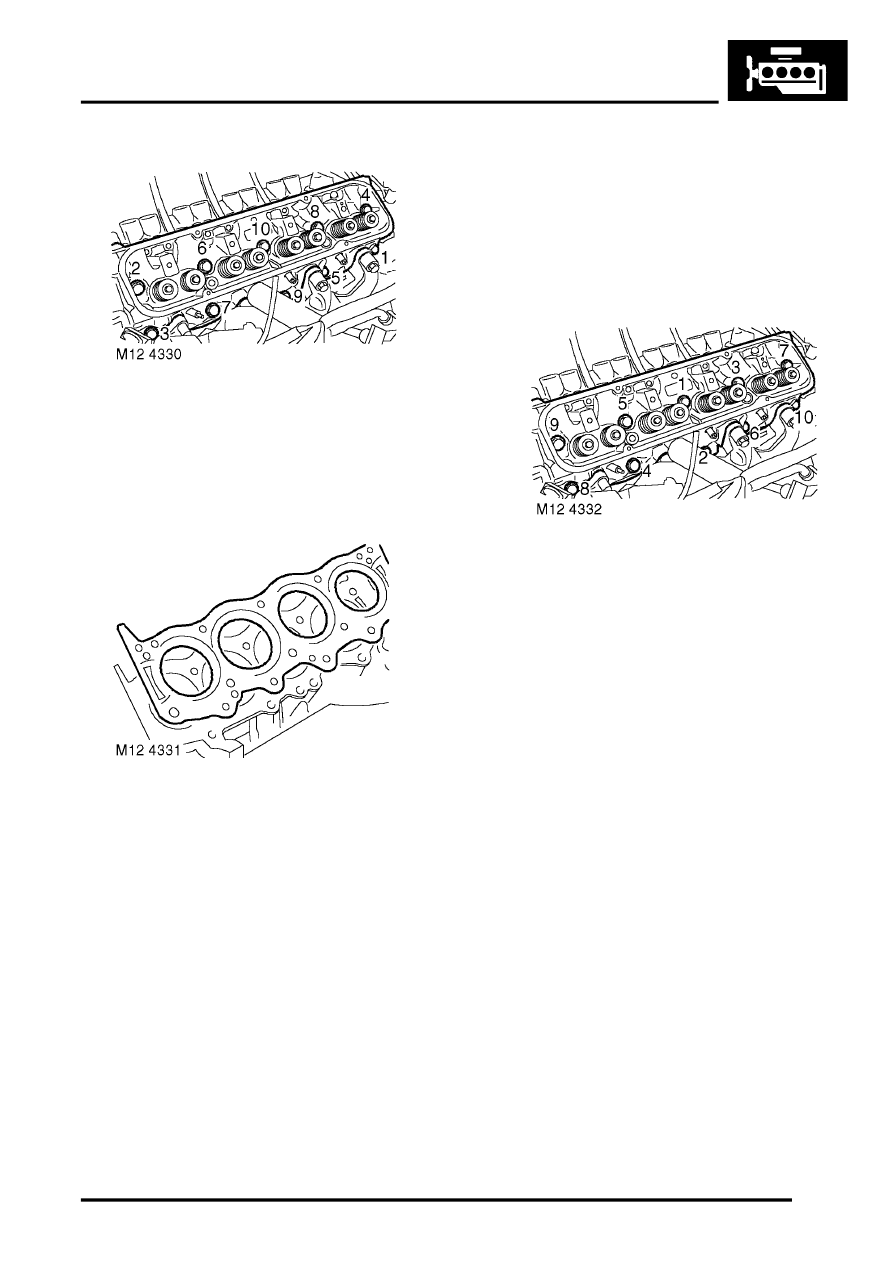

9. In the sequence shown, remove 10 bolts

securing the cylinder head to block. Discard the

bolts.

10. Remove cylinder head.

CAUTION: Support both ends of cylinder

head on blocks of wood.

11. Remove cylinder head gasket.

Refit

1. Clean mating faces of cylinder block and head

using suitable gasket removal spray and a

plastic scraper, ensure that bolt holes in block

are clean and dry. Clean mating faces of

cylinder head and exhaust manifold.

CAUTION: Do not use a metal scraper or

machined surfaces may be damaged.

2. Check head and block faces for warping and

pitting. If out of specification, renew head.

3. Models with SAI: Using a 5/8 in x 20 TPI

(threads per inch) UNF tap having a class 2A

thread, remove deposits from secondary air

injection adapter tappings in cylinder head.

CAUTION: Ensure that tap used has 20 TPI.

4. Fit cylinder head gasket with the word 'TOP'

uppermost.

CAUTION: Gaskets must be fitted dry.

5. Carefully fit cylinder head and locate on

dowels.

6. Lightly lubricate new cylinder head bolt threads

with clean engine oil.

7. Noting that bolts 1, 3 and 5 are longer than the

remainder, fit cylinder head bolts and tighten in

the sequence shown to 20 Nm (15 lbf.ft) then

90

°

, and finally a further 90

°

.

CAUTION: Do not tighten bolts 180

°

in one

operation.

8. Models with SAI: Fit new air injection adapters

and using a 9 mm hexagonal drive bit, tighten

to 33 Nm (24 lbf.ft).

CAUTION: Do not use an air tool to tighten

adapters.

9. Clean push rods.

10. Lubricate ends of push rods with clean engine

oil.

11. Fit push rods in their removed order.

12. Clean bases of rocker pillars and mating faces

on cylinder head.

13. Clean contact surfaces on rockers, valves and

push rods.

14. Lubricate contact surfaces and rocker shaft

with clean engine oil.

15. Fit rocker shaft assembly and engage push

rods.

16. Fit rocker shaft bolts and progressively tighten

to 40 Nm (30 lbf.ft).