Discovery II

REAR AXLE

OVERHAUL

51-13

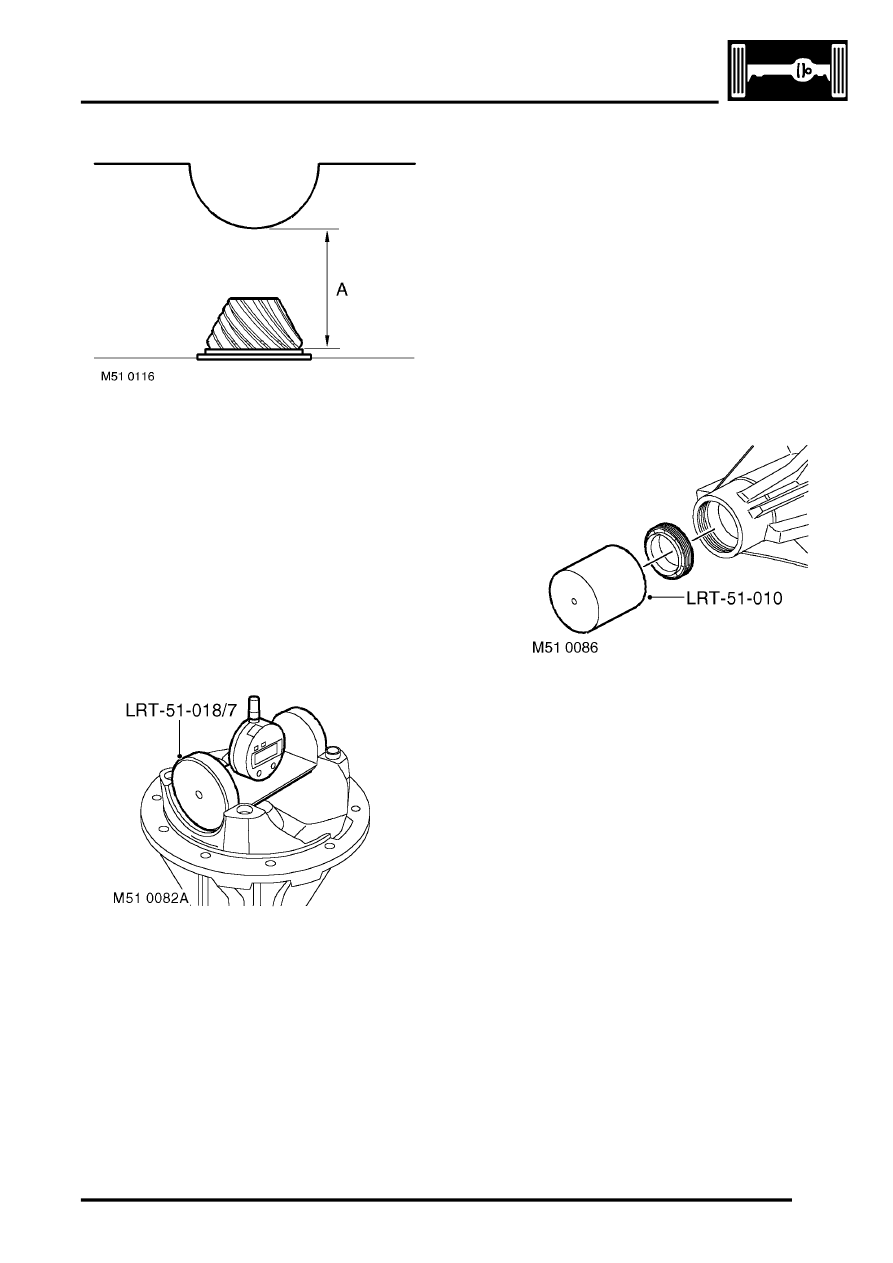

21. Pinion height setting procedure:

l

'A' = Nominal pinion height setting, 74.390.

l

'B' = Setting block height.

l

'C' = Head height setting.

l

'C' = 'A' - 'B'. Subtract nominal pinion height

'A' from setting block height 'B' (on side of

setting block).

l

Example: 74.390 - 73.130 = 1.26 mm

(2.929' - 2.88' = 0.049'). Therefore pinion

head height reading is 1.260 mm

±

0.025

mm (0.049'

±

0.001').

CAUTION: Setting block height must be

checked using figures on side of block.

22. Align setting gauge LRT-51-018/7 to setting

block, rock gauge to obtain minimum reading. If

reading is lower than required reading,

decrease shim size. If reading is higher than

required reading, increase shim size.

23. Using LRT-51-003 to restrain pinion flange,

remove bolt and washer. Remove pinion

flange.

24. Remove pinion, collect tail bearing and tail

bearing shim.

25. Remove pinion head bearing outer race and

shim. Discard shim. Ensure bearing race

recess is clean and free from burrs.

26. Fit calculated shim, and using LRT-51-018/4 fit

head bearing outer race.

27. Fit pinion, pinion tail bearing and tail bearing

shim.

28. Fit pinion flange and bolt and washer. Using

LRT-51-003 to restrain pinion flange, tighten

bolt to 100 Nm (74 lbf.ft).

29. Rotate pinion in both directions to settle

bearings.

30. Recheck pinion Torque to Turn, adjust if

necessary.

31. Recheck pinion head height.

32. Using LRT-51-003 to restrain pinion flange,

remove bolt and washer. Remove pinion

flange.

33. Discard bolt.

34. Using LRT-51-010 fit pinion seal.

35. Ensure spacer and tail bearing are correctly

located.

36. Fit pinion, pinion flange and washer.

37. Fit new pinion flange bolt and tighten to 100 Nm

(74 lbf.ft).

38. Lightly oil differential bearings.

39. Ensure spring dowels are fitted in bearing caps.

40. Fit differential bearing outer races and locate

differential assembly into housing.

41. Fit bearing caps and tighten bolts to 10 Nm (7.5

lbf.ft).