Discovery II

TRANSFER BOX - LT230SE

41-60

OVERHAUL

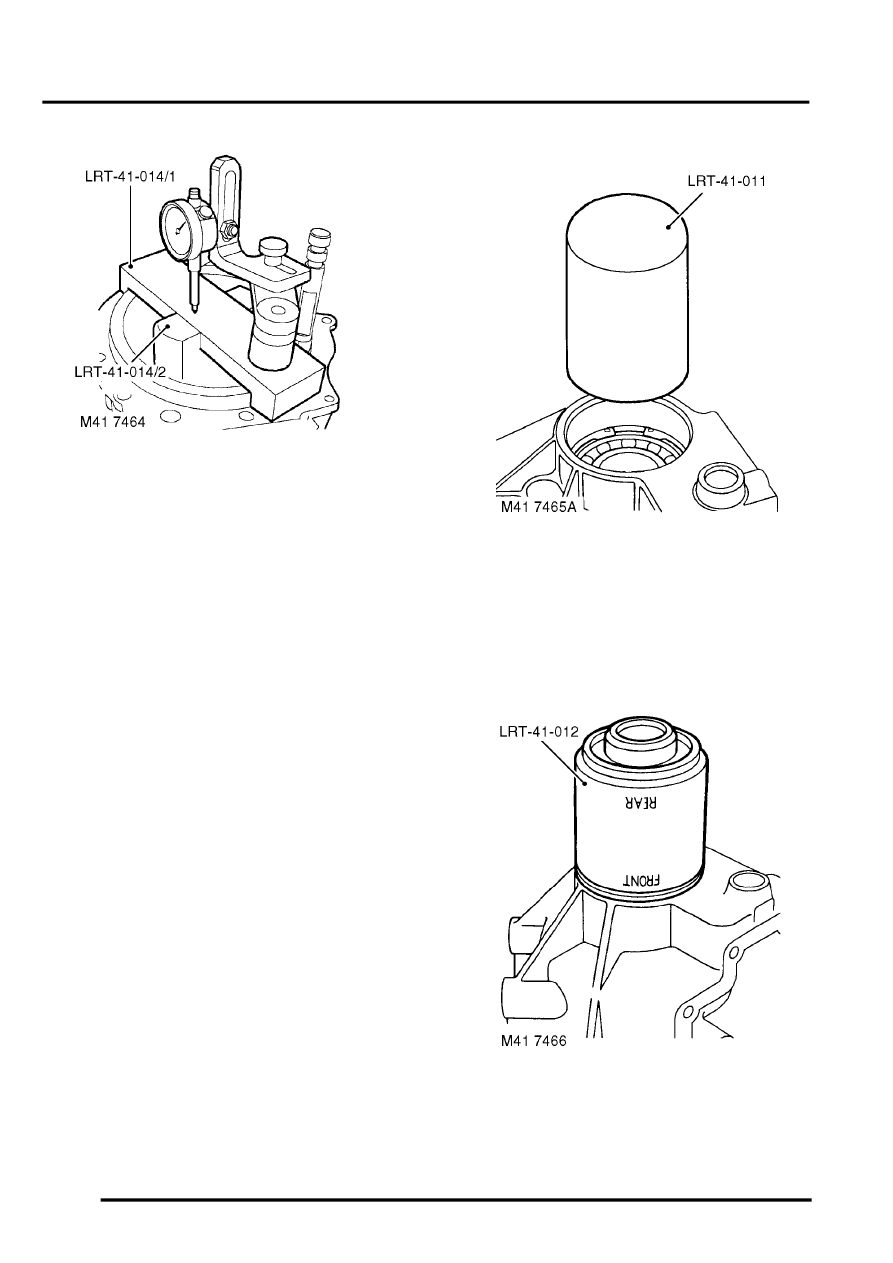

31. Position depth block tool LRT-41-014/2 and

cross bar tool LRT-41-014/1 to front output

housing.

32. Position DTI to tool LRT-41-014/1 cross bar

and zero DTI on depth block.

33. Position DTI to cross bar and record reading

obtained.

34. Using the formula: 3.05 mm (0.120 in)+B-

A=D where: B=Height difference recorded

between depth block and cross bar.

A=Average of readings to differential front

bearing outer track. D=Thickness of shim

required to give differential bearing pre-load of

0.05 mm (0.002 in).

35. From the resultant figure obtained, select

appropriate thickness shim from the range

available.

36. Shims are available from 2.00 to 3.25 mm

(0.08 to 0.13 in) thickness, rising in increments

of 0.05 mm (0.002 in).

37. Heat the front output housing to 100

°

C (210

°

F)

and fit new output shaft bearing using tool

LRT-41-011.

38. Allow housing to air cool.

39. Fit new bearing retaining circlip ensuring that

circlip is fully seated.

40. Using tool LRT-41-012, fit new output shaft oil

seal. Check that oil seal is just contacting

circlip.

CAUTION: Oil seal must be fitted dry.