Discovery II

TRANSFER BOX - LT230SE

OVERHAUL

41-45

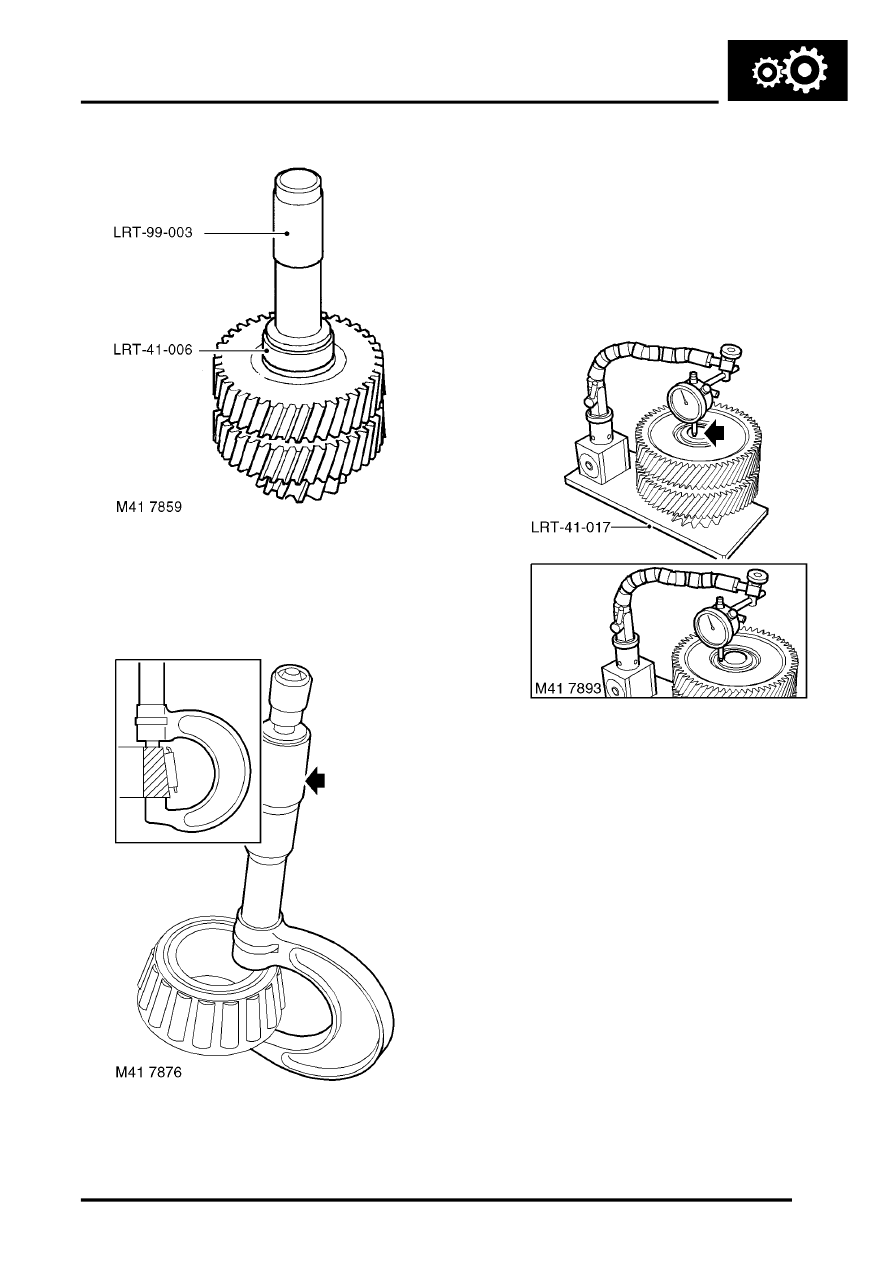

4. 03 Model Year onwards: Using tools LRT-99-

003 and LRT-41-006, fit bearing tracks to

intermediate gears ensuring that tracks are fully

seated against shoulders in gears.

5. Using a micrometer, measure the width of each

bearing inner track.

6. Record each reading as measurement 'A' and

'B', both measurements should fall within the

range of 21.95 to 22.00 mm (0.864 to 0.866 in).

7. Fit inner bearing track 'A' onto tool LRT-41-017

and position intermediate gear cluster onto

bearing 'A'.

8. Fit inner bearing track 'B' to intermediate gear,

apply finger pressure to bearing inner track

and rotate intermediate gear 5 to 10 turns to

settle in bearing rollers.

9. Attach a DTI to base of tool LRT-41-017 , zero

gauge on top of tool post and take 2

measurements at 180

°

of the step height

between the top of the tool post and the

bearing inner track. Take an average of the two

readings and record this as measurement 'C'.

Measurement 'C' should be in the range of 0.15

to 0.64 mm (0.006 to 0.025 in).

10. Using the formula 103.554 mm (4.0769 in) -'A'-

'B'-'C', calculate the length of bearing spacer

required. From the result of the calculation

round DOWN to the nearest length of spacer

available to give a correct bearing pre-load of

0.005 mm (0.002 in). 40 spacers are

available ranging in length from 58.325 mm

(2.296 in) to 59.300 mm (2.335 in) rising in

increments of 0.025 mm (0.001 in).

11. Remove intermediate gear assembly from tool

LRT-41-017.

12. Lubricate and fit bearings and selected spacer

to intermediate gear.

13. Position tool LRT-41-004 through bearings

and spacer.