Discovery II

TRANSFER BOX - LT230SE

41-70

OVERHAUL

7. Position dial gauge with stylus contacting input

gear, push input gear rearwards and zero

gauge.

8. Push input gear forwards and note gauge

reading.

9. Calculate thickness of shim required using the

formula - A+B+C=D where:

l

A= Thickness of installed shim - 3.15 mm

(0.12 in)

l

B= Recorded end-float.

l

C= Required pre-load - 0.05 mm (0.002 in).

l

D= Thickness of shim required.

10. If an alternative shim is required to establish

correct pre-load, fit an alternative shim. Shims

are available from 3.15 to 4.00 mm (0.12 to

0.16 in) thickness, in increments of 0.05 mm

(0.002 in).

11. Remove 2 bolts, remove bearing housing and

input gear.

12. Lubricate input gear and bearings with

recommended oil.

13. Position input gear into main casing.

14. Apply sealant, Part No. STC 4600to bearing

housing and cover.

15. Apply sealant, Part No. STC 50552 to threads

of cover bolts and stud nut.

16. Position bearing housing/cover, align reference

marks and tighten bolts and stud nut by

diagonal selection to 45 Nm (33 lbf.ft).

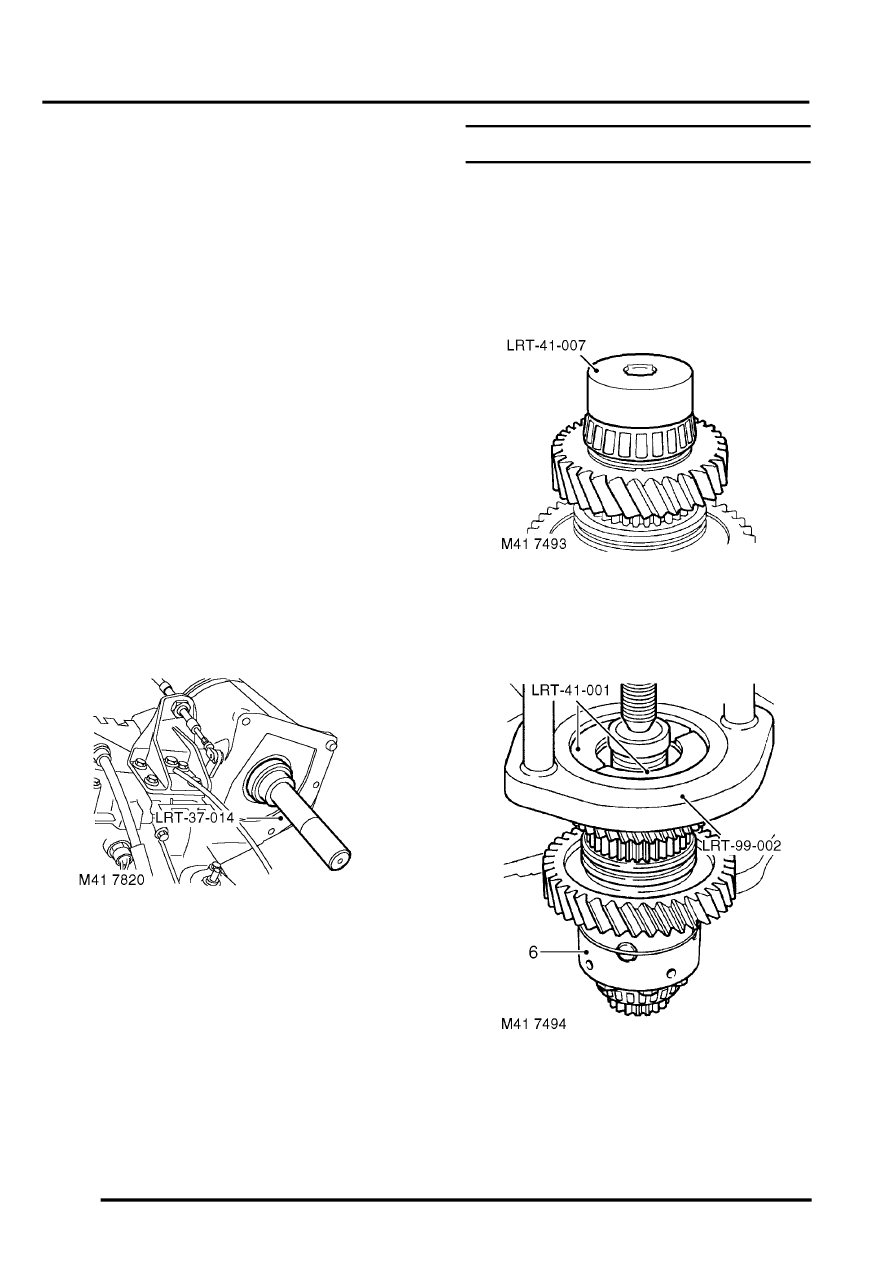

17. Using tool LRT-37-014 fit new input shaft oil

seal.

CAUTION: Oil seal must be fitted dry.

Low gear - differential

$% 41.20.62

Disassembly

OVERHAUL, Dog clutch - differential lock.

2. Secure differential in a soft jawed vice.

3. Release staking from bearing retaining nut.

4. Using tool LRT-41-007 remove and discard

bearing retaining nut.

5. Position tool LRT-99-002. to a vice.

6. Position tool LRT-41-001 around rear

differential bearing, position differential to tool

LRT-99-002 and press off bearing.