300Tdi Discovery

12

ENGINE

14

REPAIR

39. Remove remaining bell housing to cylinder block

bolts.

40. Remove starter motor ground strap from

chassis.

41. Remove stands and lower vehicle.

42. Position hydraulic trolley jack under bell housing

to support gearbox when engine and gearbox

are separated.

43. Fit lifting chains to engine. Carefully raise hoist a

little, ease engine and gearbox apart, steady

engine on hoist.

44. Ensure no components remain that will prevent

engine being removed.

45. Slowly raise engine clear of engine

compartment. Move engine away from vehicle

and place on a suitable engine stand.

Refit

46. Fit lifting chains to engine. Raise engine using

hoist.

47. Lower engine into engine compartment. Ensure

all components are clear of engine assembly.

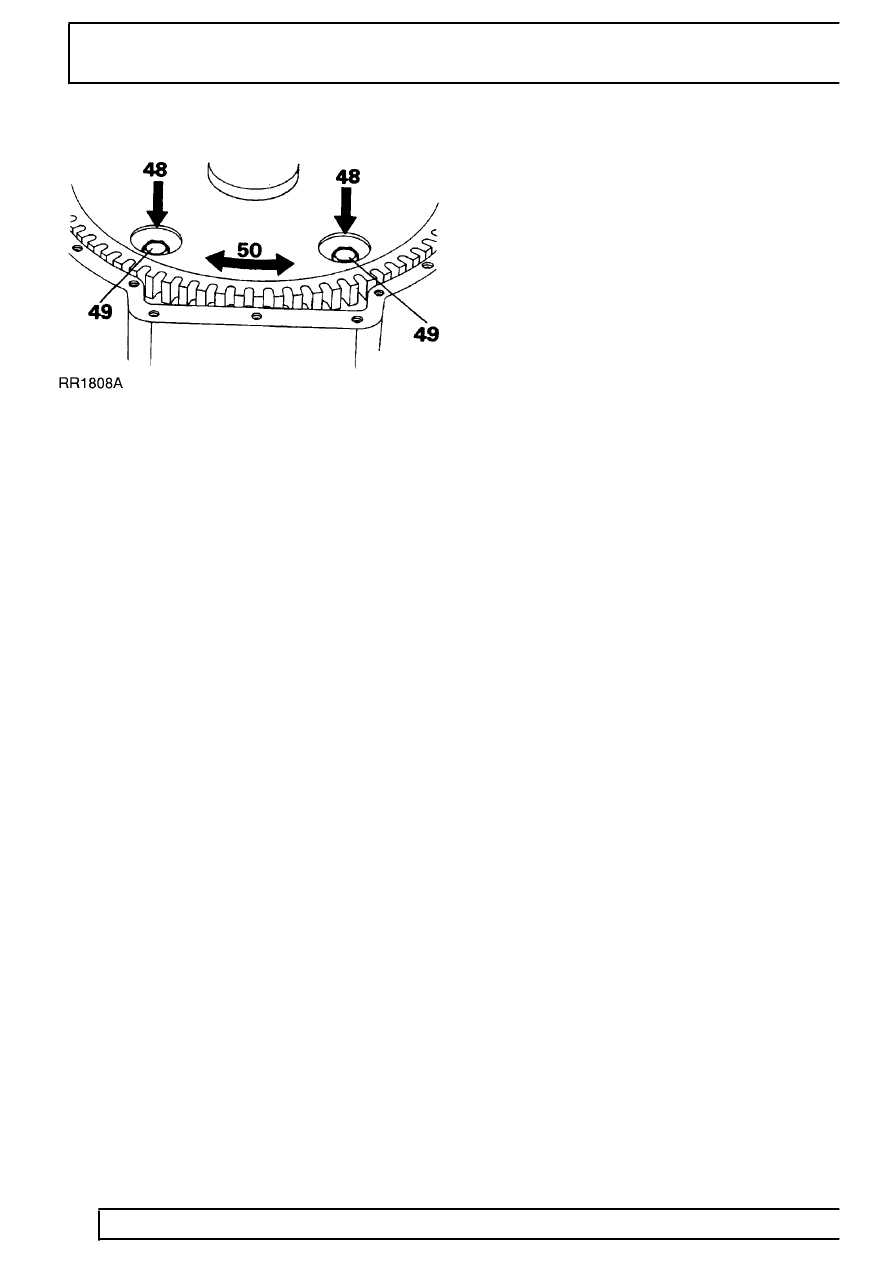

48. Automatic vehicles: With assistance, manoeuvre

engine until bottom two engine and bellhousing

bolt holes align. Ensure that two cylinder block

dowels locate in bell housing.

Manual vehicles: Lower engine into position.

Locate primary pinion into clutch. Engage bell

housing dowels.

49. Fit two bolts and partially tighten.

50. Remove jack and lower hoist until engine rests

securely on engine mounting brackets.

51. Fit top two bell housing securing bolts. Tighten

to

40 Nm.

52. Fit remaining bell housing to cylinder block bolts.

Tighten to

40 Nm.

53. Automatic vehicles: With assistance, rotate

crankshaft pulley, line up marked holes in drive

plate and torque converter. Fit two bolts.

Tighten to

40 Nm.

54. Rotate crankshaft 180

°

and fit remaining two

bolts tighten to correct torque,

40 Nm.

55. Fit new gasket and refit bottom cover, tighten

bolts to

9 Nm.

56. Fit new exhaust flange gaskets, fit exhaust to

manifold.

57. Refit all harnesses, ground straps breather pipes

and hoses at rear of engine.

58. Raise engine and refit engine mounting rubbers,

tighten nuts to

20 Nm.

59. Remove temporary lifting eye ETC 5964 and

reverse instructions 1 to 23, ensuring that all

electrical plugs and harnesses are fitted in

correct locations.