Repairing the Plenum Chamber in a 300Tdi Discovery for Improved Fuel System Efficiency

MFI

13

REPAIR

44. Grease new air seal with Admax L3 or

Energrease LS3. Push seal down shaft, into

counterbore until seal is 6.0 mm (0.236 in) below

face of plenum.

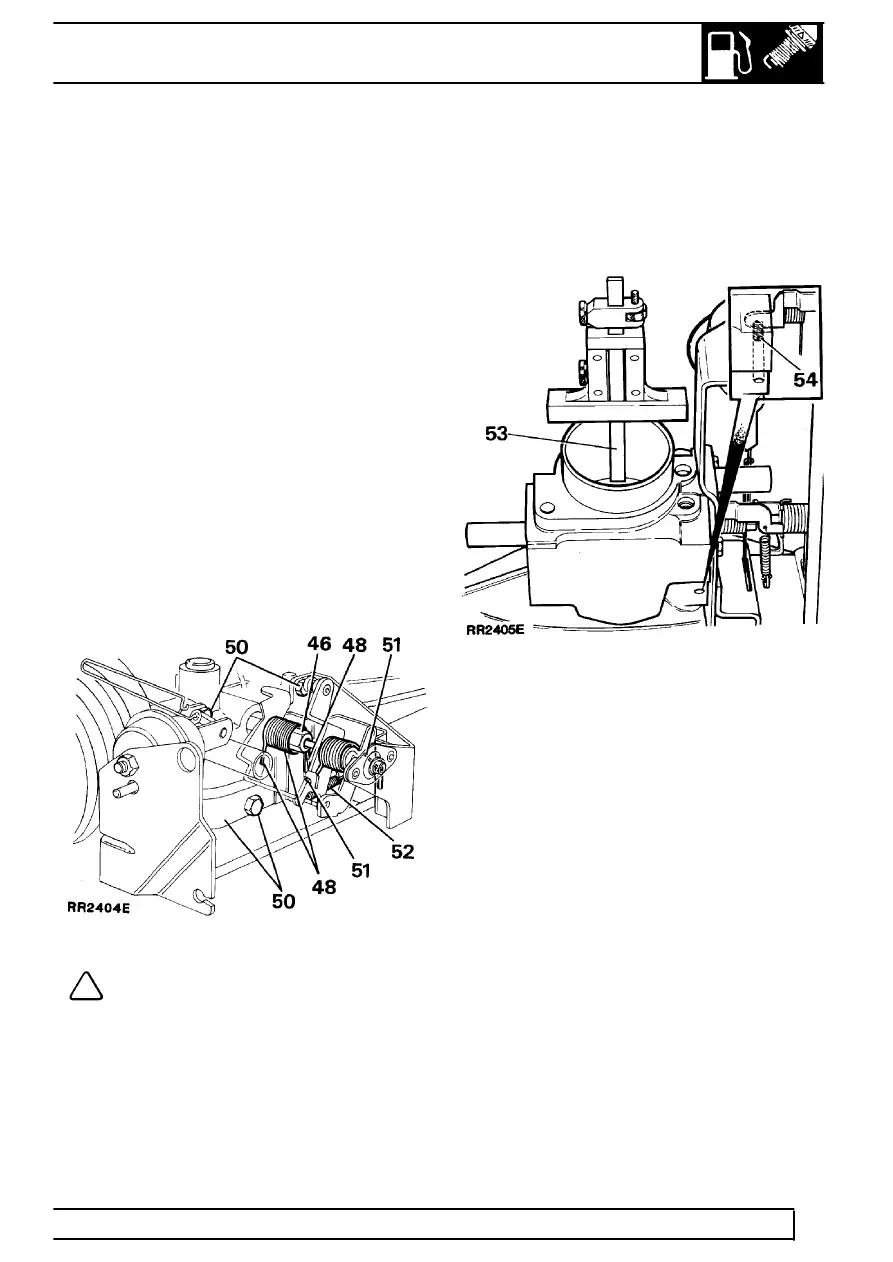

Throttle levers and bracket - assemble

45. Fit stop lever to throttle shaft, a new tab washer

and secure with throttle shaft nut.

46. Holding stop lever on stop, tighten throttle shaft

nut securely, bend over tabs to lock nut in

position.

47. Fit inboard throttle return spring noting that small

hooked end of spring is nearest plenum.

48. Locate hooked end of inboard spring on stop

lever. Wind up straight end one full turn and

locate in appropriate slot.

49. Fit countershaft to interconnecting nut of throttle

valve shaft.

50. Secure throttle bracket assembly to plenum.

Secure with three retaining bolts.

51. Ensure hooked end of outboard spring is

retained by lever, wind spring up one full turn

and locate free end in appropriate slot.

52. Fit overtravel spring.

Lightly grease throttle return and overtravel

springs with Admax L3 or Energrease LS3.

NOTE: If new throttle levers have been

fitted, minimum throttle setting of disc

must be checked to ensure it is 90˚ to

bore.

53. Using a depth vernier or depth micrometer,

check dimension from mouth of bore to top and

bottom of valve disc. Dimension must be within

0.5 mm (0.019 in) total indicator reading across

diameter of disc.

54. If dimension is out of limits, adjust small set

screw below stop lever.

Refit

55. Reconnect and adjust cruise control actuator

link.

See Actuator Link Setting

56. Clean joint faces of plenum and ram housing.

Apply ’Hylomar’ sealant, refit plenum chamber.

Tighten bolts to

26 Nm.

57. Reverse removal procedure.