300Tdi Discovery

REAR AXLE AND FINAL DRIVE

5

OVERHAUL

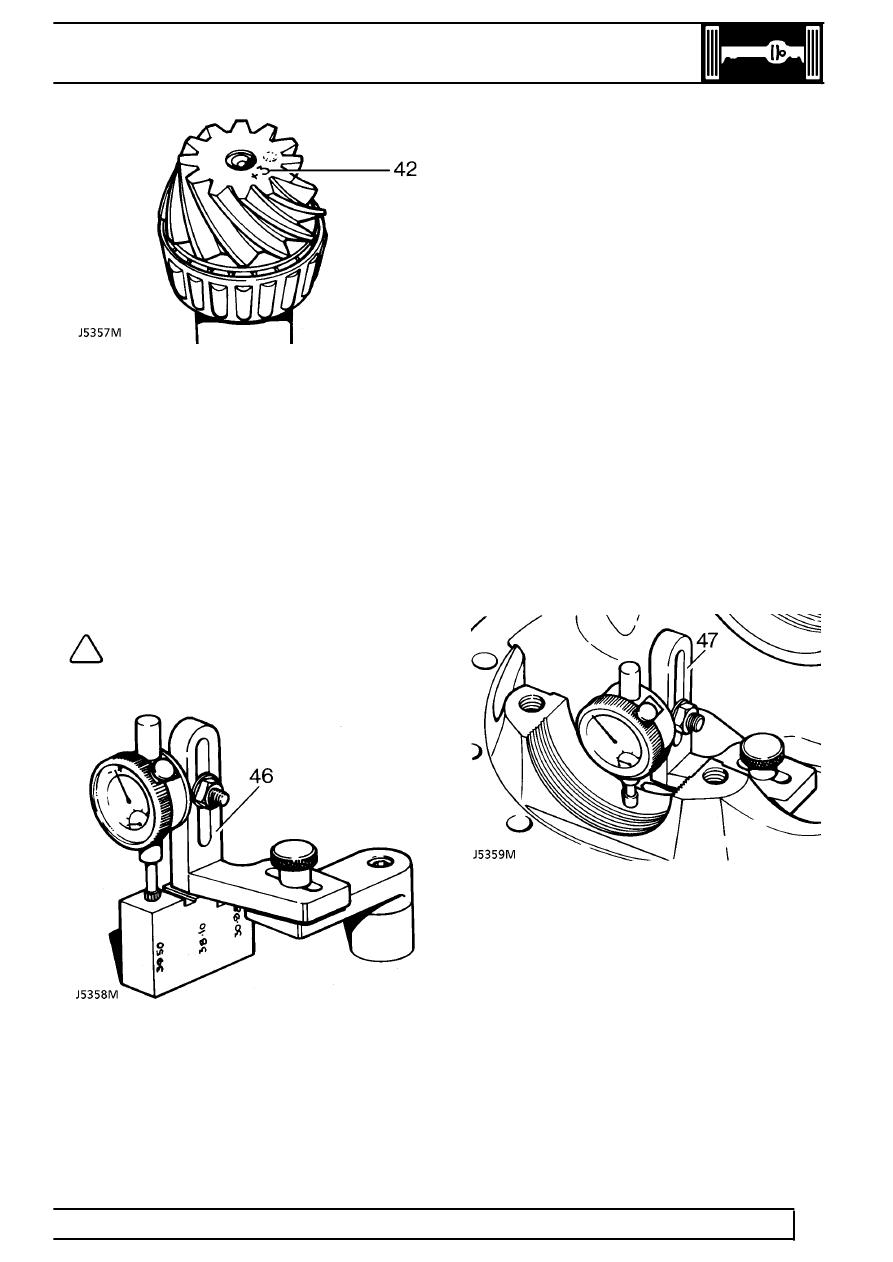

43. Nominal setting dimension is represented by

setting gauge block LRT-54-503. Referenced

from pinion end face to bottom radius of

differential bearing bore.

Drive pinion adjustment

44. Ensure pinion end face is free of burrs around

etched markings.

45. Remove keep disc from magnetized base of dial

gauge tool.

46. Place dial gauge and setting block on surface

plate. Zero dial gauge trace pin on setting block.

NOTE: Setting block has three height

settings heights.

Use 39.50mm setting mark for this differential.

Pinion height shims

PART No.

INCH

MM

FTC3853

.061

1.548

FTC3854

.060

1.523

FTC3855

.059

1.498

FTC3856

.058

1.473

FTC3857

.057

1.448

FTC3858

.056

1.423

FTC3859

.055

1.398

FTC3860

.054

1.373

FTC3861

.053

1.348

FTC3862

.052

1.323

FTC3863

.051

1.298

FTC3864

.050

1.273

FTC3865

.049

1.248

FTC3866

.048

1.223

FTC3867

.047

1.198

FTC3868

.046

1.173

47. Position dial gauge centrally on pinion end face,

register on lowest point on one differential

bearing bore. Note dial gauge measurement

from zeroed setting.