300Tdi Discovery

51

REAR AXLE AND FINAL DRIVE

6

OVERHAUL

48. Repeat on other bearing bore. Add readings

then halve sum to obtain mean reading. Note

whether trace pin has moved up or down from

zero.

A.

Where trace pin moves down, reading is

equal to thickness of shims to remove, to

bring pinion to nominal.

B.

Where trace pin moves up, reading is

equal to thickness of shims to add, to bring

pinion to nominal.

49. Before adjusting shim thickness: check pinion

face marking. If a plus (+) figure, subtract in

thousandths of an inch from shim thickness

figure.

50. If pinion has a minus (-) figure, add amount to

shim thickness figure.

Adjust shim thickness under pinion head bearing

track as necessary.

INCH

MM

.001

=

.025

.002

=

.05

.003

=

.075

.004

=

.10

.005

=

.125

.006

=

.15

.007

=

.175

.008

=

.20

.009

=

.225

.010

=

.25

NOTE: Where dial indicator is metric

conversion must be made to inches when

measuring and selecting shims.

51. Recheck pinion height setting. If setting is

correct, mean reading of dial gauge will agree

with figure marked on pinion end face.

For example, with end face marking of +3, dial

gauge reading should indicate pinion is +0.003

in.

Bearing pre-load adjustment

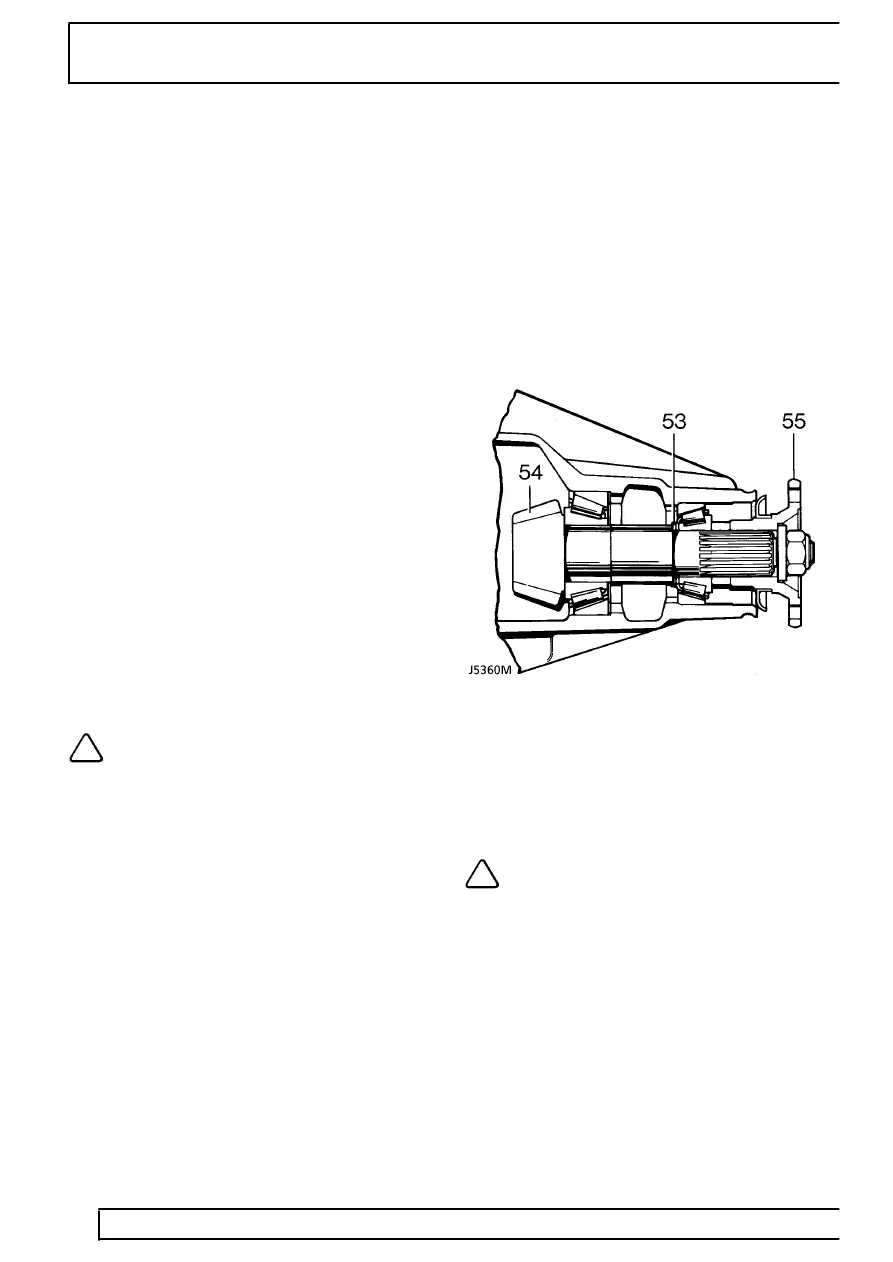

52. Remove the pinion flange, pinion, outer bearing

and spacer.

53. Slide new shim, of same thickness as original

(bearing pre-load) into position on pinion shaft. If

fitting a new shim use thickest shim 2.155 mm.

54. Fit pinion to pinion housing and fit outer bearing

and spacer (front differential only).

55. Fit driving flange, washer and nut.

56. Do not fit oil seal at this stage.

57. Tighten pinion flange nut to

130 Nm. Force to

rotate pinion shaft is 3Nm using new bearings.

Change shim as necessary to obtain reading.

Thicker shim will reduce pre-load. Thinner shim

will increase pre-load.

NOTE: If using original bedded in

bearings, pre-load figure is 1.5 Nm.

58. Remove pinion flange.