300Tdi Discovery

54

FRONT AXLE AND FINAL DRIVE

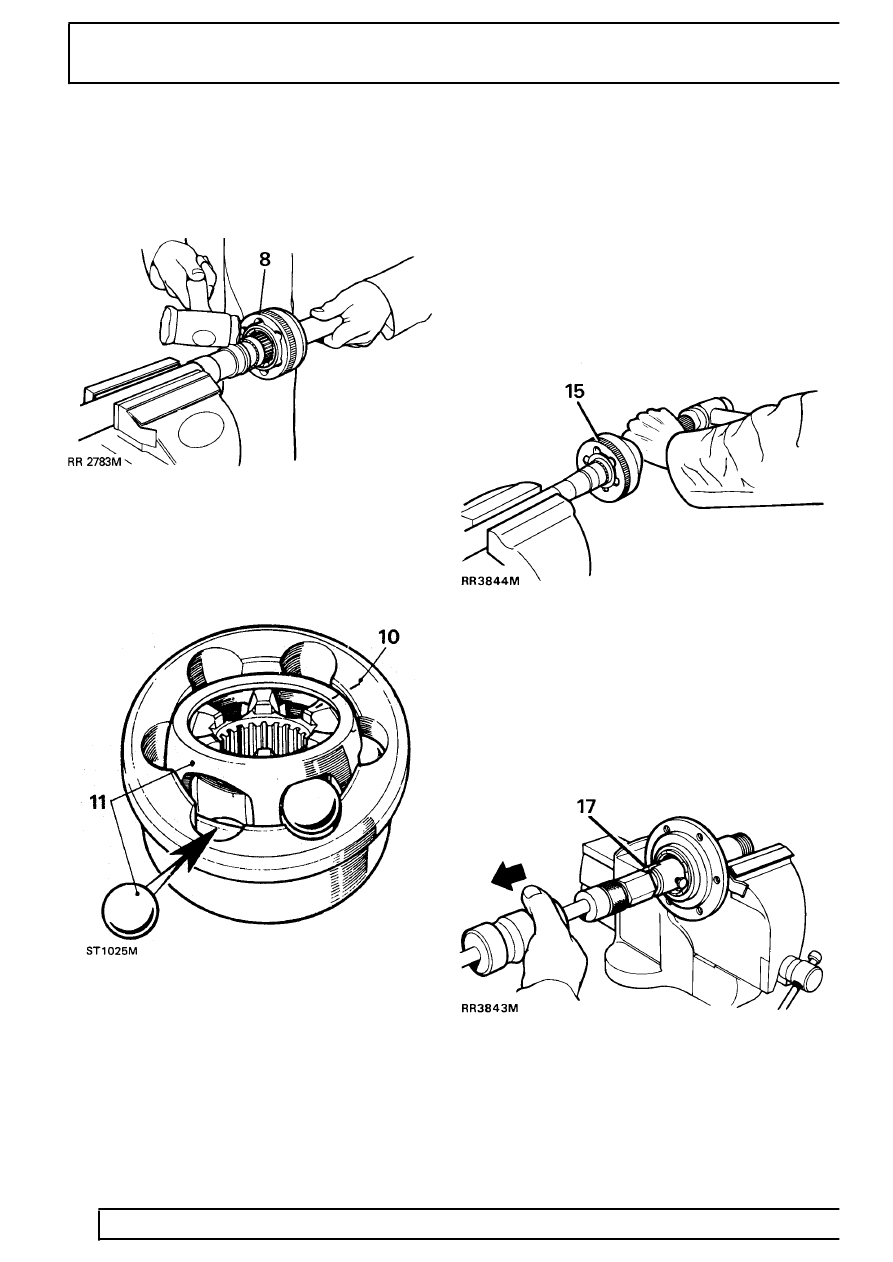

8

OVERHAUL

Remove constant velocity joint from axle shaft

7. Hold axle shaft firmly in a soft jawed vice.

8. Using a soft mallet drive constant velocity joint

from shaft.

9. Remove circlip and collar from axle shaft.

Constant velocity joint

10. Mark positions of constant velocity joint, inner

and outer race and cage for reassembly.

11. Swivel cage and inner race to remove balls.

12. Examine all components in particular inner and

outer track, cage balls and bearing surfaces for

damage and excessive wear.

13. Maximum acceptable end-float on assembled

joint 0,64mm. Renew if worn or damaged.

Lubricate with a recommended oil during

assembly.

Fit constant velocity joint to axle

14. Fit collar and a new circlip.

15. Engage constant velocity joint on axle shaft

splines and using a soft mallet, drive joint in fully.

Renew stub axle,thrust ring, oil seal and bearing

16. Drill and chisel off thrust ring taking care to avoid

damaging stub axle.

17. Remove bearing and oil seal using special tool

LRT-37-004 and slide hammer LRT-99-004.

Ensure lip of tool locates behind bearing to to

drive it out.

18. Repeat instruction for removal of oil seal.