300Tdi Discovery

57

STEERING

2

REPAIR

POWER STEERING BOX

Service repair no - 57.10.01

General precautions

1. Whenever any part of system, is removed or

disconnected, utmost cleanliness must be

observed.

2. Disconnected ports and hoses must be plugged

to prevent ingress of dirt. If metal sediment is

found in system, establish cause rectify and

flush system.

3. Do not start engine until reservoir is full as pump

will be damaged.

4. Metric pipe fittings are used with ’O’ ring pipe

ends on fittings to steering box.

5. Follow normal ’O’ ring replacement procedure

whenever pipes are disconnected.

6. Ensure compatible metric components when

fitting replacement pipes.

CAUTION: Before removing any parts of

steering linkage, it is imperative that road

wheels are positioned straight ahead.

Then steering wheel removed to prevent rotary

coupler being wound up or damaged.

CAUTION: After refitting steering linkage

parts follow correct procedure to ensure

that road wheels, steering box and

steering wheel are correctly positioned relative to

each other when in straight ahead condition. If

steering wheel requires repositioning, ensure that

drive pegs on rotary coupler are correctly

positioned before steering wheel is replaced.

This ensures drive pegs locate in their holes in

rear of steering wheel.

After final alignment connect rotary coupler

multiplug, tighten steering wheel securing nut and

fit air bag - if fitted or steering wheel trim pad.

NOTE: When drag link is disconnected

from steering box, travel available at

steering wheel to each full lock is not

equal.

Remove

1. Site vehicle on level surface.

2. Open bonnet[hood].

3. Remove filler cap from power steering fluid

reservoir.

4. Clean steering box.

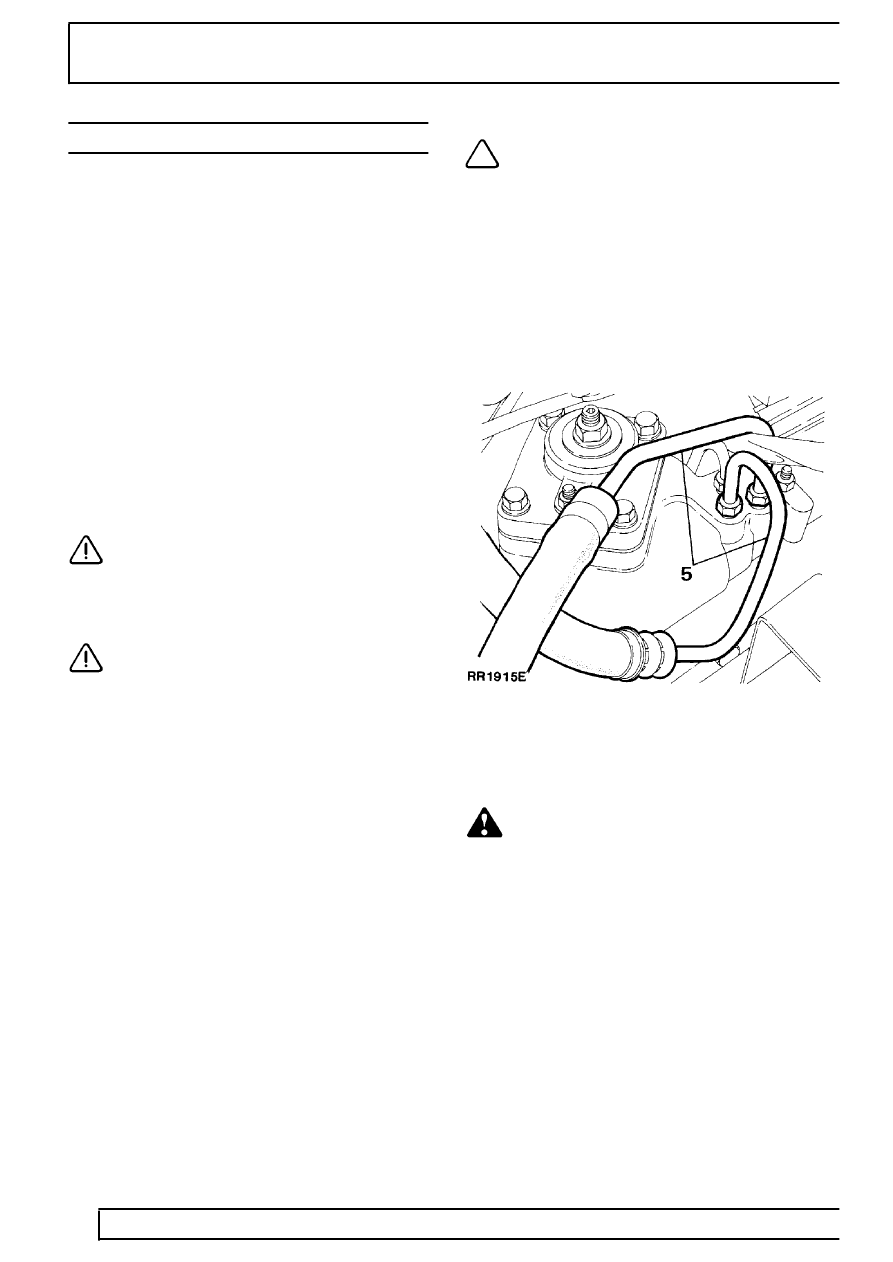

5. Disconnect feed and return pipes from steering

box.

6. Plug open pipes and steering box ports to

prevent ingress of dirt.

7. Support chassis front on axle stands. Or raise

vehicle on a hoist.

WARNING: Ensure wheels are chocked,

parking brake is applied, and low range

selected.