Freelander System Description and Operation

AIR CONDITIONING

DESCRIPTION AND OPERATION

82-7

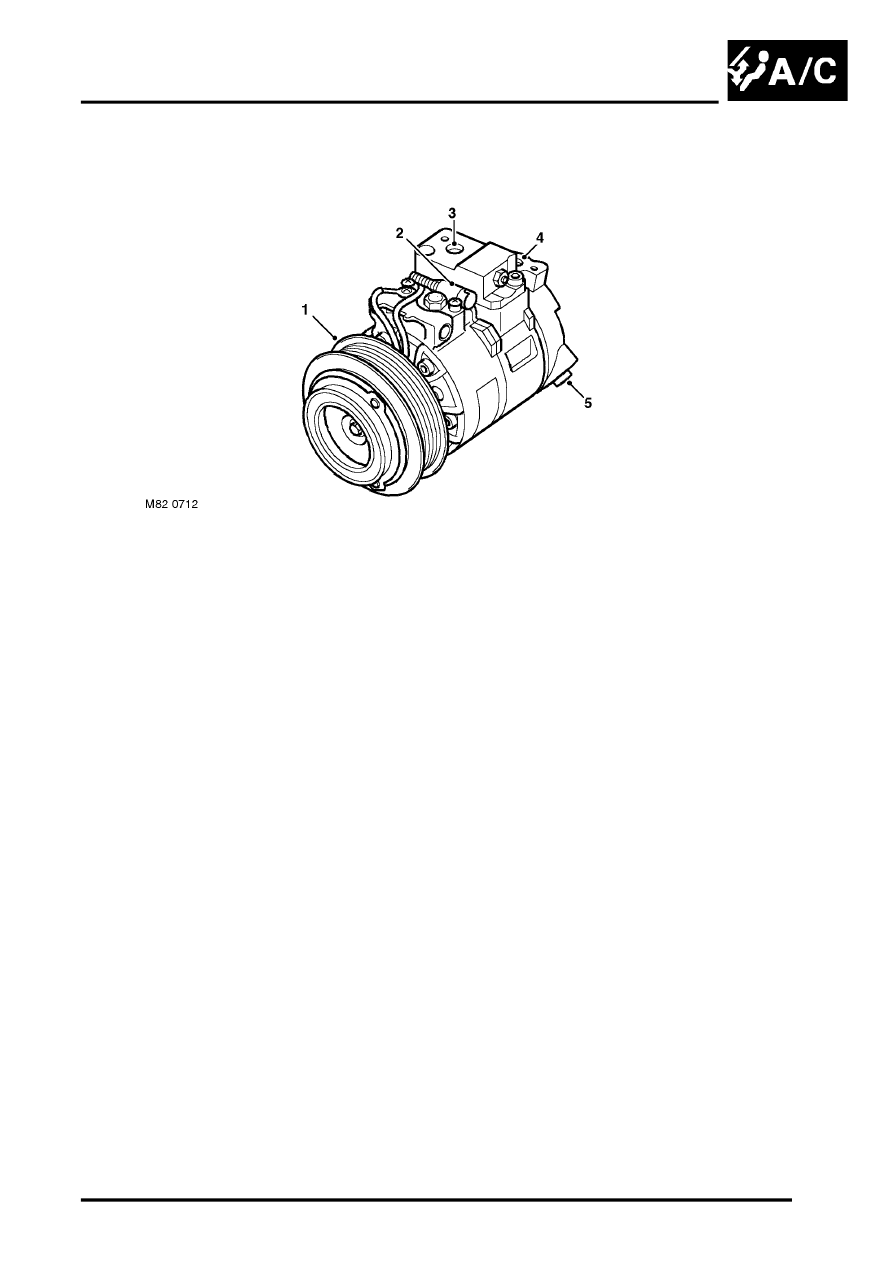

Compressor

1 Pulley

2 Clutch connector

3 Inlet connection

4 Outlet connection

5 Control valve vent

A variable displacement compressor is driven from the crankshaft via the ancillary drive belt. An electro-mechanical

clutch is used to engage and disengage the drive between the drive belt pulley and the compressor. Operation of the

compressor clutch is controlled by the Engine Control Module (ECM).

Power to the A/C compressor clutch is via the normally open contacts of an associated A/C compressor clutch relay

which is located in the engine compartment fusebox. When the coil of the relay is grounded by the ECM, the relay

contacts close and the clutch is powered to engage the compressor to the drive belt pulley.

When the compressor is operational, pressurised refrigerant is circulated through the system. The compressor

pressurises low pressure, warm, vaporised refrigerant which it receives from the evaporator, causing the refrigerant

vapour to become very hot. The high pressure vaporised refrigerant is passed from the compressor to the condenser

mounted in front of the radiator. The refrigerant increases in pressure and temperature as it passes through the

compressor, then releases heat and changes state from vapour to liquid in the condenser.

The compressor is attached to a mounting bracket on the engine, and is a seven cylinder swash plate unit with

variable displacement. Operation of an electrically actuated clutch is controlled by the Engine Control Module (ECM).