Freelander Steering Valve Unit Overview

STEERING

DESCRIPTION AND OPERATION

57-7

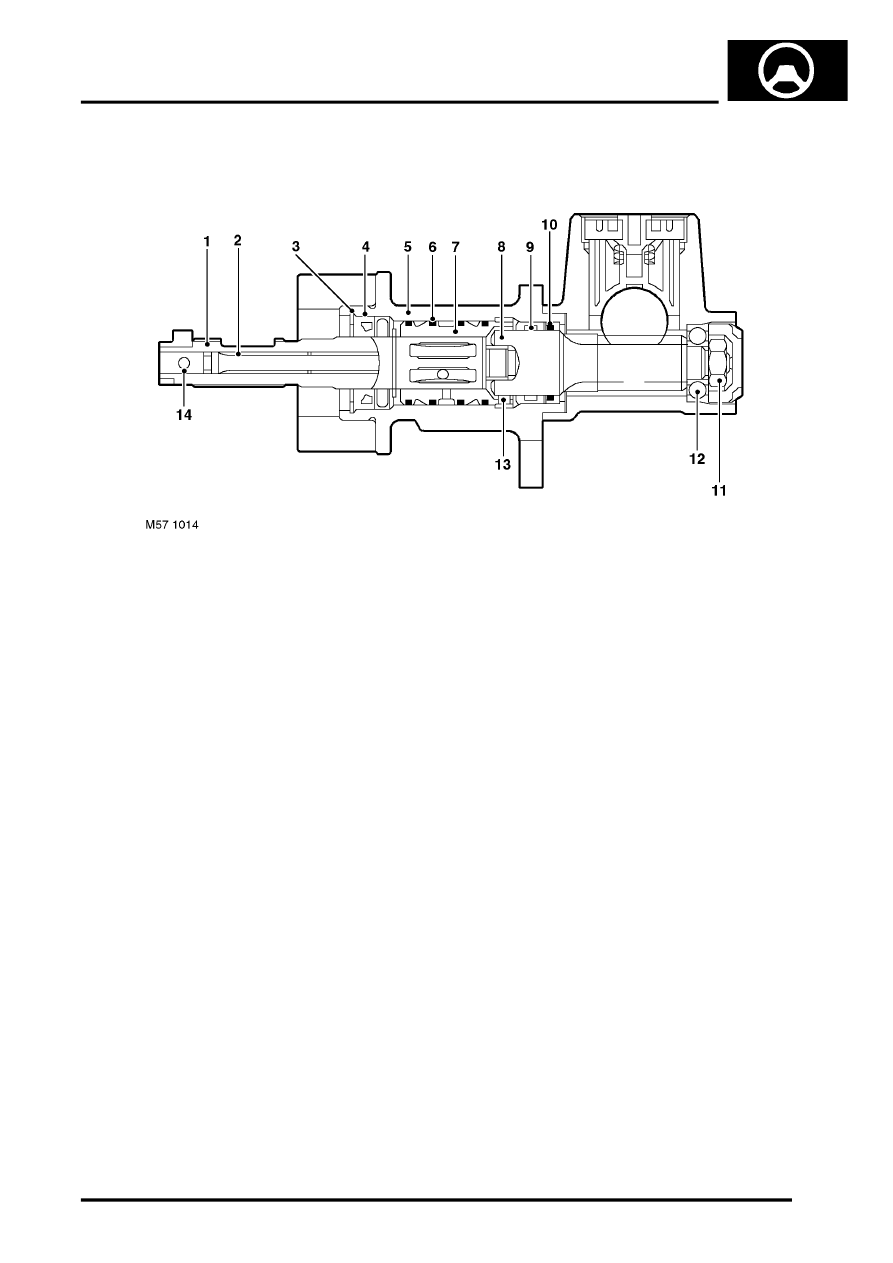

Valve Unit

1 Input shaft

2 Torsion bar

3 Circlip

4 Oil seal

5 Valve housing

6 PTFE ring (4 off)

7 Outer sleeve

8 Pinion shaft

9 Bearing

10 Oil seal

11 Nut

12 Bearing

13 Pin - pinion shaft to outer sleeve

14 Pin - input shaft to torsion bar

The valve unit is an integral part of the steering rack. The principal function of the valve unit is to provide maximum

power assistance (i.e. when parking) with minimum effort required to turn the steering wheel.

The cast outer casing of the valve unit has four ports which provide the connections for pressure feed from the PAS

pump, return to the fluid reservoir and pressure feeds from the valve unit to the annulus area and the full area of the

cylinder. A non return valve and seal is fitted in the pressure feed port from the PAS pump.

The valve unit comprises an outer sleeve, input shaft, torsion bar and a pinion shaft. The valve unit is coaxial with the

pinion shaft which is connected to the steering column via the input shaft. The valve unit components are located in

a housing which is attached to a mating casting on the steering rack main body and secured with screws.

The outer sleeve is located in the main bore of the valve unit. Three annular grooves are machined on its outer

diameter. PTFE rings are located between the grooves and seal against the bore of the valve unit. Holes are drilled

radially in each annular groove through the wall of the sleeve. The bore of the outer sleeve is machined to accept the

input shaft. Six equally spaced slots are machined in the bore of the sleeve. The ends of the slots are closed and do

not continue to the ends of the outer sleeve. The radial holes in the outer sleeve are drilled into each slot.

The input shaft is splined at its outer end. The inner end of the input shaft forms a dog-tooth which mates with a slot

in the pinion shaft. The fit of the dog-tooth in the slot allows a small amount of relative rotation between the input shaft

and the pinion shaft before the dog-tooth contacts the wall of the slot. This ensures that, if the power assistance fails,

the steering can be operated manually without over stressing the torsion bar. The central portion of the input shaft has

equally spaced longitudinal slots machined in its circumference. The slots are arranged alternately around the input

shaft.