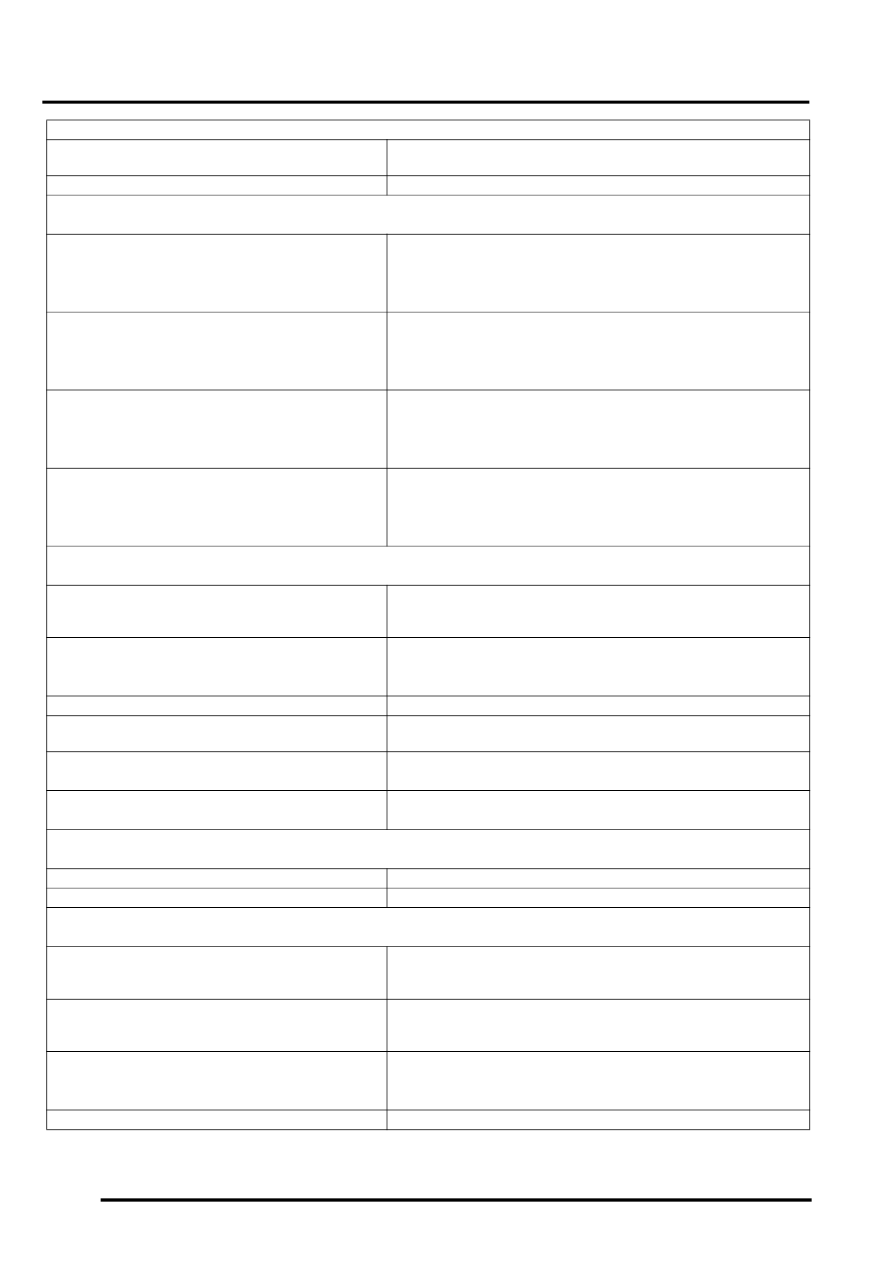

Freelander Service Procedures

GENERAL DATA

04-14

Clearance in bore 20 mm (0.75 in.) from bottom of

cylinder bore

0.034 - 0.035 mm (0.0013 - 0.0014 in.)

Maximum ovality

0.3 mm (0.012 in.)

Piston rings

Type:

⇒

Top compression ring

Chrome plated steel

⇒

2nd compression ring

Chrome plated cast iron

⇒

Oil control ring

Stainless steel top and bottom rails with expander ring

New ring to groove clearance:

⇒

Top compression ring

0.05 - 0.08 mm (0.0020 - 0.0031 in.)

⇒

2nd compression ring

0.04 - 0.07 mm (0.0012 - 0.0024 in.)

⇒

Oil control ring

0.010 - 0.180 mm (0.0004 - 0.0071 in.)

Ring fitted gap 20 mm (0.75 in) from top of bore:

⇒

Top compression ring

0.20 - 0.35 mm (0.008 - 0.014 in.)

⇒

2nd compression ring

0.28 - 0.45 mm (0.011 - 0.018 in.)

⇒

Oil control ring

0.25 - 1.00 mm (0.010 - 0.039 in.)

Piston ring width:

⇒

Top compression ring

3.1

±

0.15 mm (0.122

±

0.006 in.)

⇒

2nd compression ring

3.15 - 3.45 mm (0.124 - 0.136 in.)

⇒

Oil control ring

2.286 - 2.438 mm (0.090 - 0.096 in.)

Camshaft

Type

Twin camshafts on each cylinder bank retained by camshaft carrier,

line bored with cylinder head. Reluctor for camshaft sensor mounted

on left hand inlet camshaft

Camshaft identification:

⇒

Inlet

Orange paint mark

⇒

Exhaust

Blue paint mark

Bearings

5 per camshaft

Drive

Toothed belt driven from crankshaft to front of inlet camshafts, 2 x

short toothed belts from rear of inlet camshafts to exhaust camshafts

Camshaft end-float

0.06 - 0.19 mm (0.002 - 0.007 in.)

⇒

Service limit

0.3 mm (0.012 in.)

Bearing clearance

0.025 - 0.059 mm (0.0010 - 0.0023 in.)

⇒

Service limit

0.1 mm (0.004 in.)

Tappets

Type

Hydraulic self-adjusting, directly operated from camshafts

Tappet outside diameter

32.959 - 32.975 mm (1.2976 - 1.2982 in.)

Valve timing

Inlet valves:

⇒

Opens

⇒

Closes

2

°

BTDC

54

°

ABDC

Exhaust valves:

⇒

Opens

⇒

Closes

50

°

BBDC

14

°

ATDC

Valve maximum lift:

Inlet valves

8.2 mm (0.32 in.)

Exhaust valves

8.8 mm (0.35 in.)

General