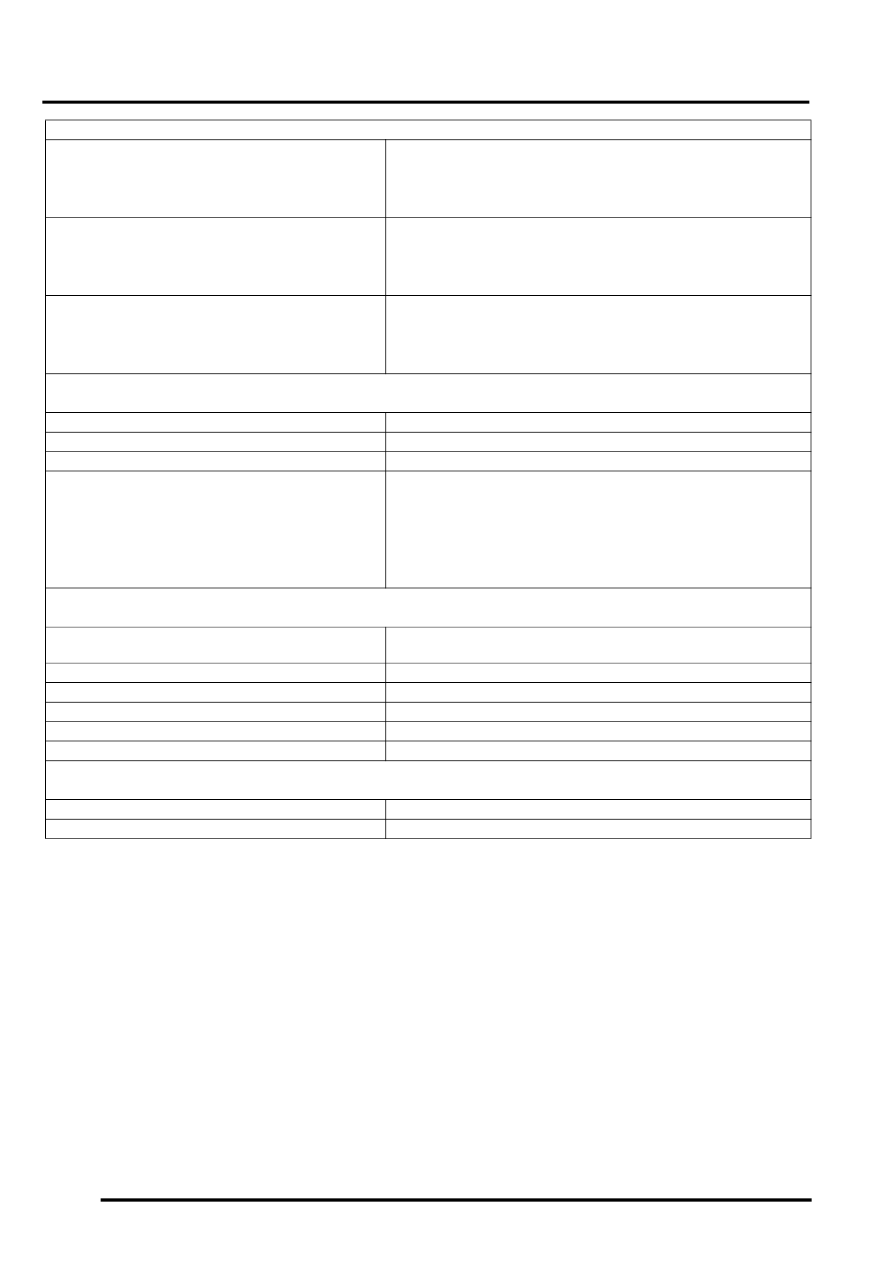

Freelander Service Procedures

GENERAL DATA

04-4

Piston rings

Type:

2 compression, 1 oil control

⇒

Top compression ring

Barrel edge, chrome plated

⇒

2nd compression ring

Taper faced

⇒

Oil control ring

Bevelled ring with spring

New ring to groove clearance (axial play):

⇒

Top compression ring

does not have to be measured

⇒

2nd compression ring

0.05 - 0.09 mm (0.0020 - 0.0035 in.)

⇒

Oil control ring

0.03 - 0.07 mm (0.0012 - 0.0028 in.)

New ring fitted gap 30 mm (1.2 in) from top of bore:

⇒

Top compression ring

0.20 - 0.35 mm (0.008 - 0.014 in.)

⇒

2nd compression ring

0.30 - 0.45 mm (0.012 - 0.018 in.)

⇒

Oil control ring

0.20 - 0.40 mm (0.008 - 0.016 in.)

Cylinder head

Type

Aluminium alloy gravity die casting

Port configuration

Cross flow

Intake ports

1 x helical, 1 x tangential

Cylinder head gasket:

⇒

Type

Multi-layer steel

⇒

Selection:

⇒⇒

1 hole

Piston protrusion up to 0.91 mm (0.036 in)

⇒⇒

2 hole

Piston protrusion 0.92 - 1.03 mm (0.036 - 0.041 in)

⇒⇒

3 hole

Piston protrusion over 1.03 mm (0.041 in)

Camshaft

Type

DOHC made from clear chill casting, hollow cast, negative cam radius;

vacuum pump driven from exhaust camshaft

Bearings

5 per camshaft

Drive

Simplex chain

Radial runout

0.047 - 0.088 mm (0.0019 - 0.0035 in)

End float

0.15 - 0.33 mm (0.006 - 0.013 in.)

Bearing clearance

0.011 - 0.034 mm (0.0004 - 0.0013 in.)

Tappets

Type

Hydraulic valve adjusters with roller finger levers