Freelander Service Procedures

SCREENS

76-4-4

REPAIRS

Refit

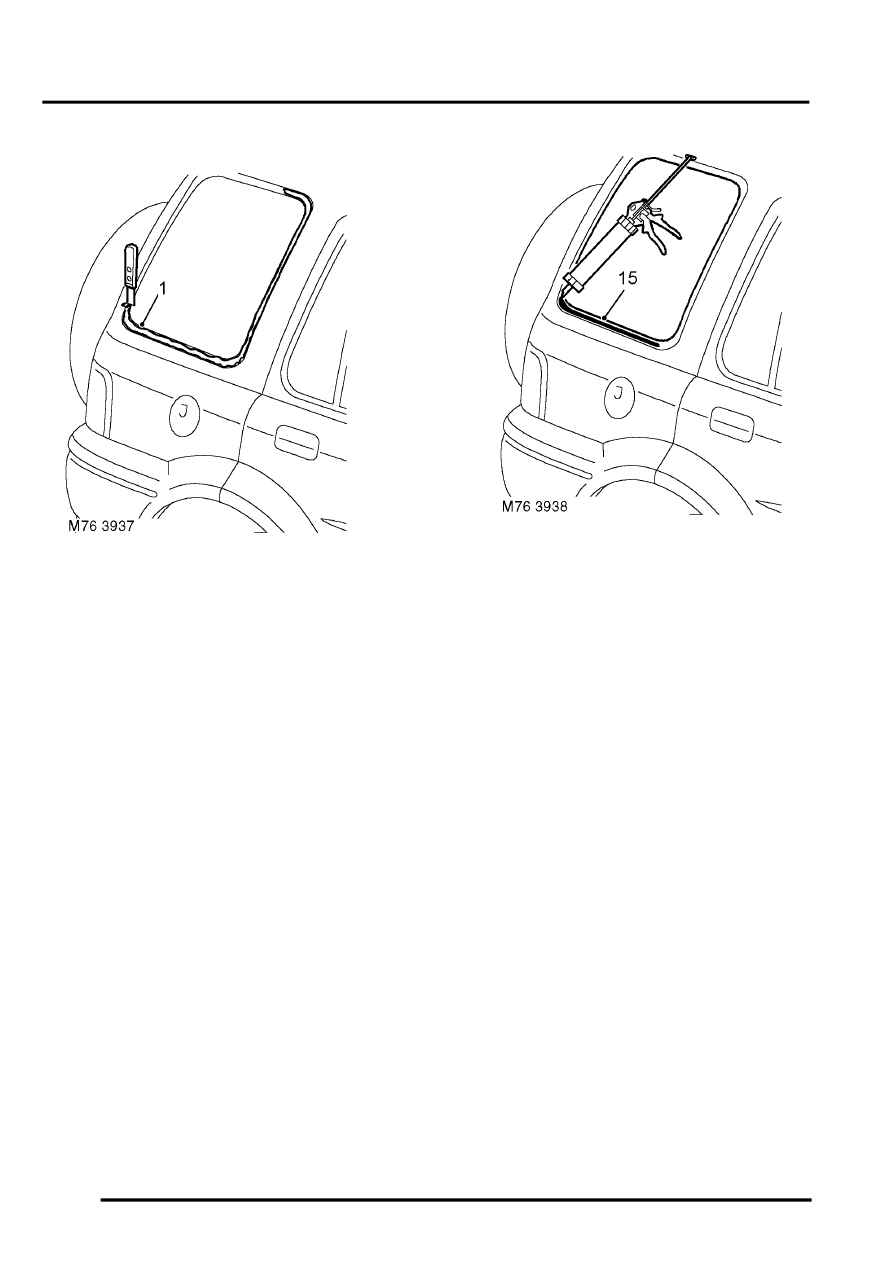

1. Carefully remove excess sealer from body

leaving a smooth surface.

2. Use a vacuum cleaner to clear away any waste.

3. Original glass: Carefully cut back old sealer to

obtain a smooth surface without damaging

obscuration band on glass.

4. Fit rubber spacer blocks to body.

5. With assistance, locate screen to body.

6. Apply masking tape reference marks to aid

fitment.

7. Remove screen and place aside.

8. Clean frame and edge of screen with solvent.

Do not touch cleaned or primed surfaces

with fingers.

9. Apply etch primer to any bare metal on frame.

10. Apply bonding agent to screen and allow to

cure.

11. Apply primer over etch primer on frame.

12. Apply activator over old sealer on frame.

13. Allow activator to cure.

14. Fit pre-cut nozzle to sealer cartridge, remove lid

and shake out crystals. Install cartridge in

applicator gun.

Nozzle will need modification to achieve

required bead section.

15. Apply a continuous bead of sealer around edge

of frame as shown. Make bead slightly thicker

at each corner.

16. Check for breaks and air bubbles in sealer.

17. Position glass to body and align to reference

tape.

18. Lightly press glass to fully seat sealer.

19. Secure glass with tape until sealer has cured.

20. Remove protective covers and tape.

21. Test sealer for leaks, apply additional sealer if

necessary. If water is used, allow sealer to dry

before testing. Spray water around glass and

check for leaks. Mark leakage points and apply

additional sealer as necessary when area is

completely dry.

22. Fit rear quarter upper casing.