Freelander Service Procedures

SCREENS

76-4-2

REPAIRS

Refit

1. Carefully remove excess sealer from body

leaving a smooth surface.

2. Use a vacuum cleaner to clear away any waste.

3. Original glass: Carefully cut back old sealer to

obtain a smooth surface without damaging

obscuration band on glass.

4. Fit spacer blocks to body.

5. With assistance, locate screen to body.

6. Apply masking tape reference marks to aid

fitment.

7. With assistance, remove screen and place

aside.

8. Clean frame and edge of screen with solvent.

Do not touch cleaned or primed surfaces

with fingers.

9. Apply etch primer to any bare metal on frame.

10. Apply bonding agent to screen and allow to

cure.

11. Apply primer over etch primer on frame.

12. Apply activator over old sealer on frame.

13. Allow activator to cure.

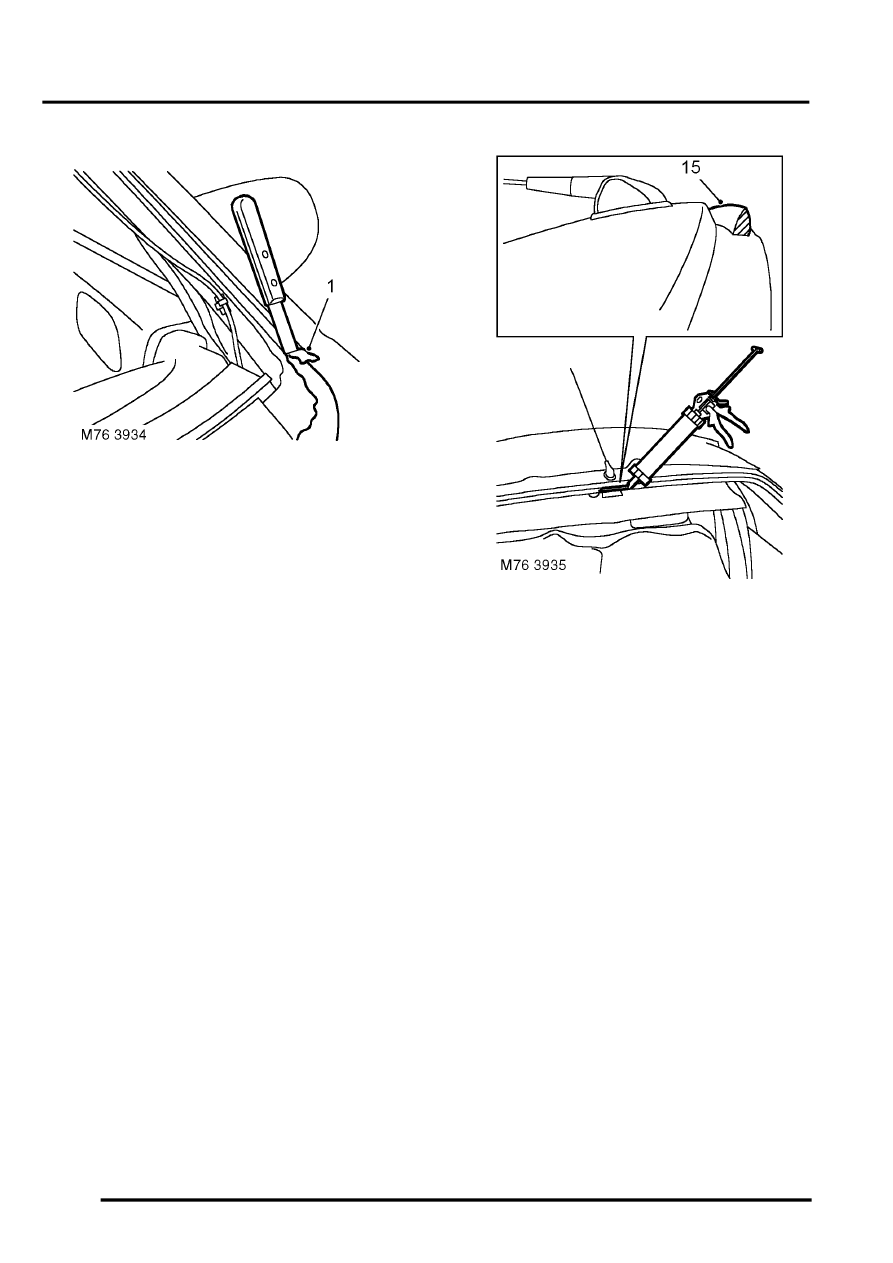

14. Fit pre-cut nozzle to sealer cartridge, remove lid

and shake out crystals, and install in applicator

gun.

Nozzle will need modification to achieve

required bead section.

15. Apply a continuous bead of sealer around edge

of frame as shown.

16. Check for breaks and air bubbles in sealer.

17. With assistance, lift screen into place and align

to screen supports and tape. Raise screen up

to roof on ratchet support blocks. Lightly press

glass to fully seat sealer.

18. Remove protective covers and tape.

19. Test sealer for leaks, apply additional sealer if

necessary. If water is used, allow sealer to dry

before testing. Spray water around glass and

check for leaks. Mark any area that leaks. Dry

glass and sealer then apply additional sealer.

20. Fit 'A' post upper trim casings.

REPAIRS, Trim finisher - 'A' post - upper -

renew.

21. Fit headlining retaining stud.

22. Fit sun visor retaining clips and sun visors.

23. Fit interior mirror.

24. Fit air intake panel.

A curing time of 6 hours is desirable, during

this time leave a window open and do not

slam the doors. If the car must be used,

drive slowly.