L322 Range Rover System Description and Operation

FUEL DELIVERY SYSTEM – V8

DESCRIPTION AND OPERATION

19-2-9

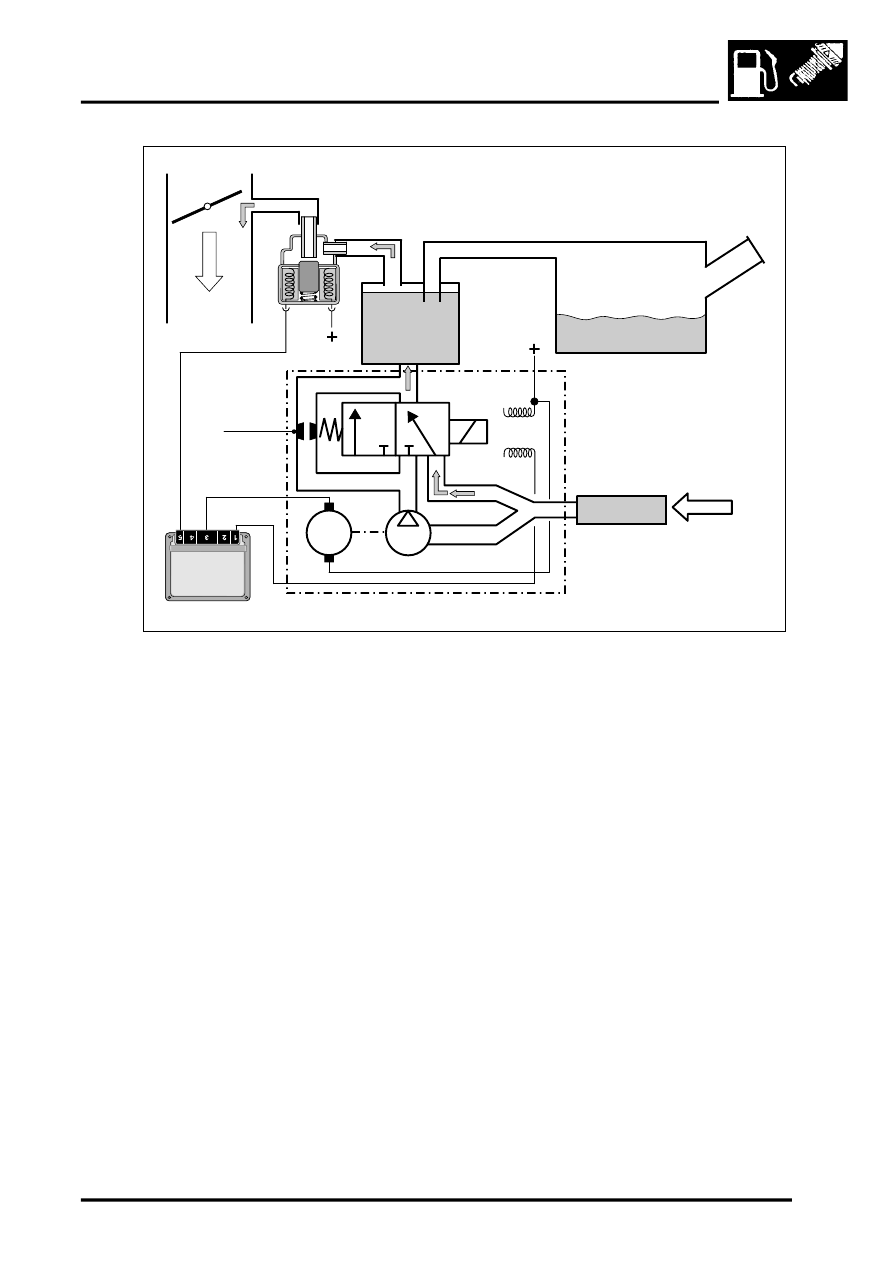

Leak Detection Normal Operation

1 Throttle plate

2 Air flow to engine

3 Purge valve

4 Charcoal canister

5 Fuel tank

6 Tank leakage detection module

7 Air intake

8 Air filter

9 Change over valve

10 Pump

11 Reference orifice

In its inactive state, filtered fresh air enters the evaporative system through the sprung open valve of the tank leakage

detection module. When the ECM activates the tank leakage detection module for leak testing, it first activates only

the pump motor. This pumps air through a reference orifice (0.5 mm) which causes the electric motor to draw a

specific amperage value. This value is then equivalent to the size of the reference orifice. The solenoid valve is then

energized which seals the EVAP system and directs the pump output to pressurize the EVAP system.

The system is detected as having a large leak if the amperage value is not realized, a small leak if the same reference

amperage is realized or no leak if the amperage value is higher than the reference leak value.

The leak detection module ensures accurate fuel system leak detection for leaks as small as 0.5mm. The pump

contains an integral DC motor which is activated directly by the engine control module. The ECM monitors the pump

motor operating current as the measurement for detecting leaks.

In its inactive state the pump motor and the change over valve of the DC Motor LDP are not energized. When purge

valve operation occurs filtered air enters the fuel system compensating for engine vacuum drawing on the

hydrocarbon vapours stored in the charcoal canister.

M

M19 3566

0.5mm

1

3

2

4

5

6

7

8

9

10

11