L322 Range Rover System Description and Operation

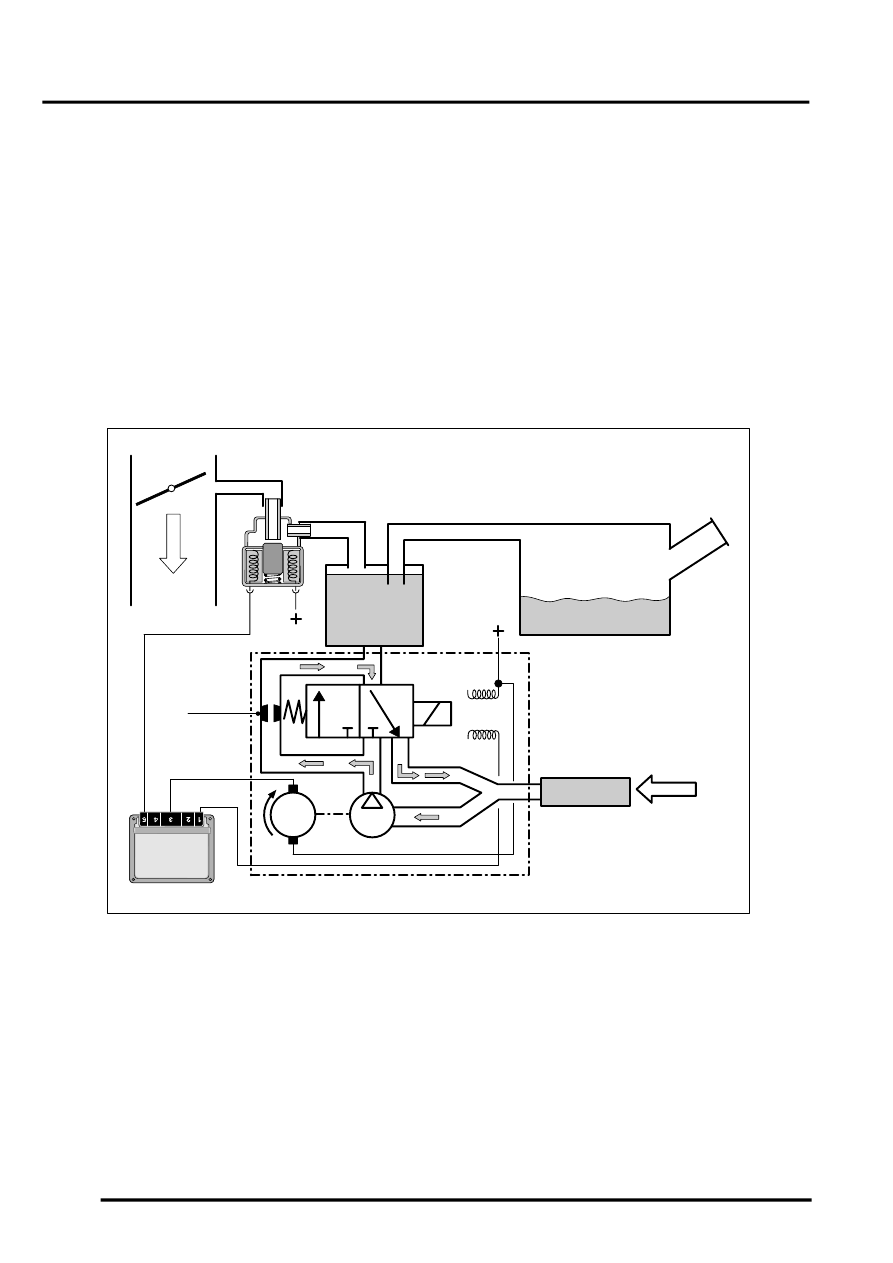

FUEL DELIVERY SYSTEM – V8

19-2-10 DESCRIPTION AND OPERATION

The ECM only initiates a leak diagnosis test every second time the criteria are met. The criteria are as follows:

l

Engine OFF with ignition switched OFF

l

Engine Control Module still in active state or what is known as “follow up mode ”(Main Relay energized, control

module and ECM components on-line for extended period after key off)

l

Prior to Engine/Ignition switch OFF condition, vehicle must have been driven for a minimum of 20 minutes

l

Prior to minimum 20 minute drive, the vehicle must have been OFF for a minimum of 5 hours

l

Fuel Tank Capacity must be between 15 and 85% (safe approximation between 1/4 - 3/4 of a tank)

l

Ambient Air Temperature between -7

°

C & 35

°

C (20

°

F & 95

°

F )

l

Altitude < 2500m (8,202 feet)

l

Battery Voltage between 11.5 and 14.5 Volts.

When these criteria are satisfied every second time, the ECM will start the Fuel System Leak Diagnosis Test. The test

will typically be carried out once a day i.e. once after driving to work in the morning, when driving home in the evening

the criteria are once again met but the test is not initiated. The following morning, the test will run again.

Phase 1 - Reference Measurement

1 Throttle plate

2 Air flow to engine

3 Purge valve

4 Charcoal canister

5 Fuel tank

6 Tank leakage detection module

7 Air intake

8 Air filter

9 Change over valve

10 Pump

11 Reference orifice

The ECM activates the pump motor. The pump pulls air from the filtered air inlet and passes it through a precise

0.5mm reference orifice in the pump assembly.

The ECM simultaneously monitors the pump motor current flow. The motor current raises quickly and levels off

(stabilizes) due to the orifice restriction. The ECM stores the stabilized amperage value in memory. The stored

amperage value is the electrical equivalent of a 0.5 mm (0.020 ”) leak.

M

M19 3579

0.5mm

1

3

2

4

5

6

7

8

9

10

11