L322 Range Rover Service Procedures

GENERAL INFORMATION

03-11

Screw Threads

General

Metric threads to ISO standards are used.

Damaged nuts, bolts and screws must always be

discarded. Cleaning damaged threads with a die or

tap impairs the strength and fit of the threads and is

not recommended.

Always ensure that replacement bolts are at least

equal in strength to those replaced. Castellated nuts

must not be loosened to accept a split-pin, except in

recommended cases when this forms part of an

adjustment.

Do not allow oil or grease to enter blind threaded

holes. The hydraulic action on screwing in the bolt or

stud could split the housing.

Always tighten a nut or bolt to the recommended

torque figure. Damaged or corroded threads can

affect the torque reading.

To check or re-tighten a bolt or screw to a specified

torque figure, first loosen a quarter of a turn, then re-

tighten to the correct torque figure.

Oil thread lightly before tightening to ensure a free

running thread, except in the case of threads treated

with sealant/lubricant, and self-locking nuts.

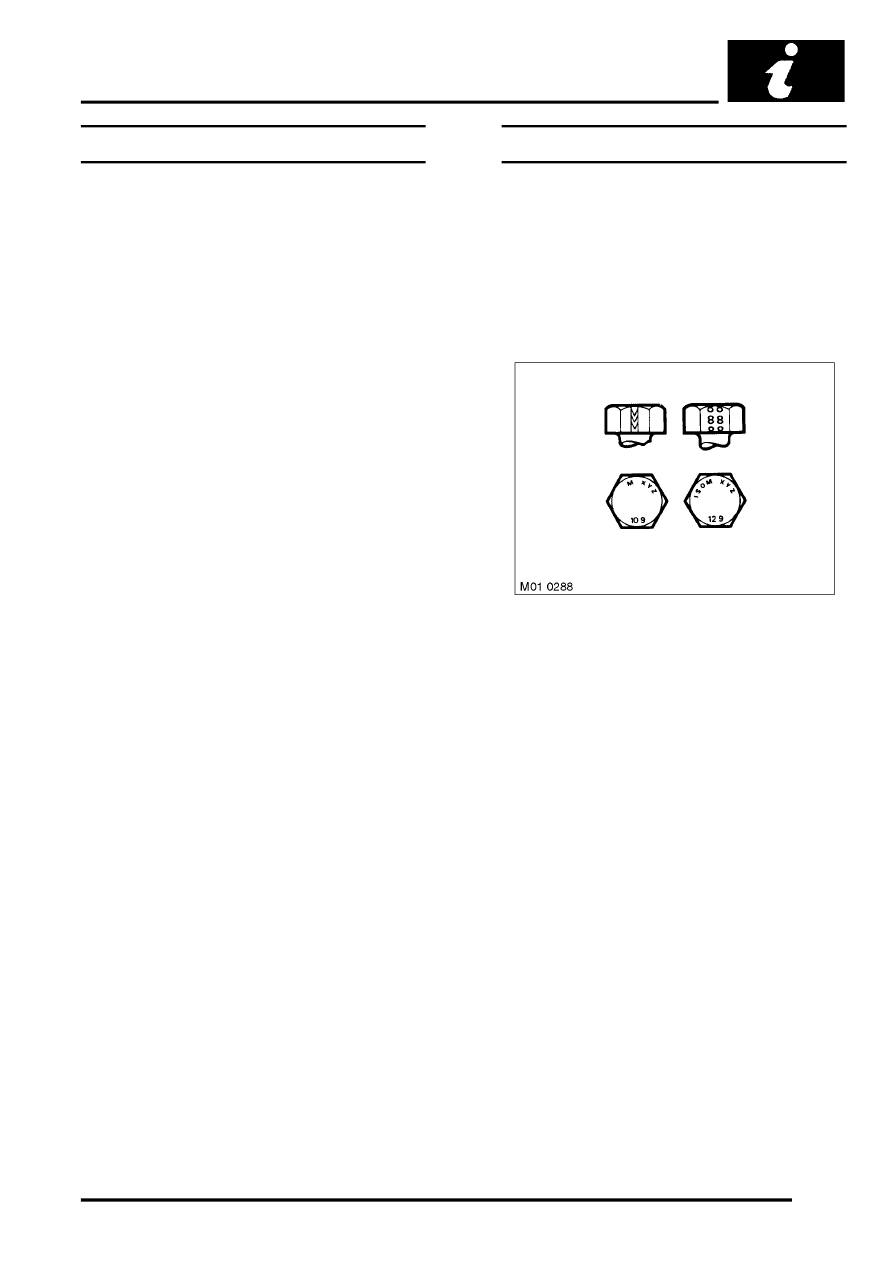

Bolt and Nut Identification

Bolt identification

A large number of the nuts and bolts used on New

Range Rover must be discarded after removing or

loosening them. Refer to the repair sections in this

Manual for further information.

CAUTION: All rear suspension fixings must be

replaced whenever they are removed.

An ISO metric bolt or screw made of steel and larger

than 6 mm in diameter can be identified by either of

the symbols ISO M or M embossed or indented on

top of the bolt head.

In addition to marks identifying the manufacturer, the

top of the bolt head is also marked with symbols

indicating the strength grade, e.g. 8.8; 10.9; 12.9;

14.9. As an alternative, some bolts and screws have

the M and strength grade symbol stamped on the

flats of the hexagon.