LR3/Disco 3

position is etched on adjoining sides of the joint to identify matching connecting rods and bearing caps. The selective

connecting rod bearings are aluminium/tin split plain bearings. The connecting rod bearing is 'sputter coated', which is a

manufacturing process that layers the bearing material to produce a higher load capacity for improved durability.

NOTE :

Connecting Rod Installation

When installing a connecting rod, ensure the back of the connecting rod faces the centre of the 'vee'.

The pistons are made from aluminium alloy and are fitted with three rings. The piston crown incorporates a pronounced

bowl; this forms the combustion chamber, which promotes swirl and turbulence necessary for good combustion and

improved emissions. In addition, the piston skirt has a molybdenum-coated surface, which counteracts scoring of the

cylinder bore and piston.

The piston also incorporates a double wave gallery within the piston crown to enhance piston cooling. The pistons are

supplied oil by means of spray jets located in the cylinder block oil gallery. These jets ensure optimum piston cooling to

counteract the high temperatures generated by the combustion process.

Each piston is installed on a wrist pin located in a aluminium/tin bushing in the connecting rod.

Piston Installation

The connecting rods are not selective.

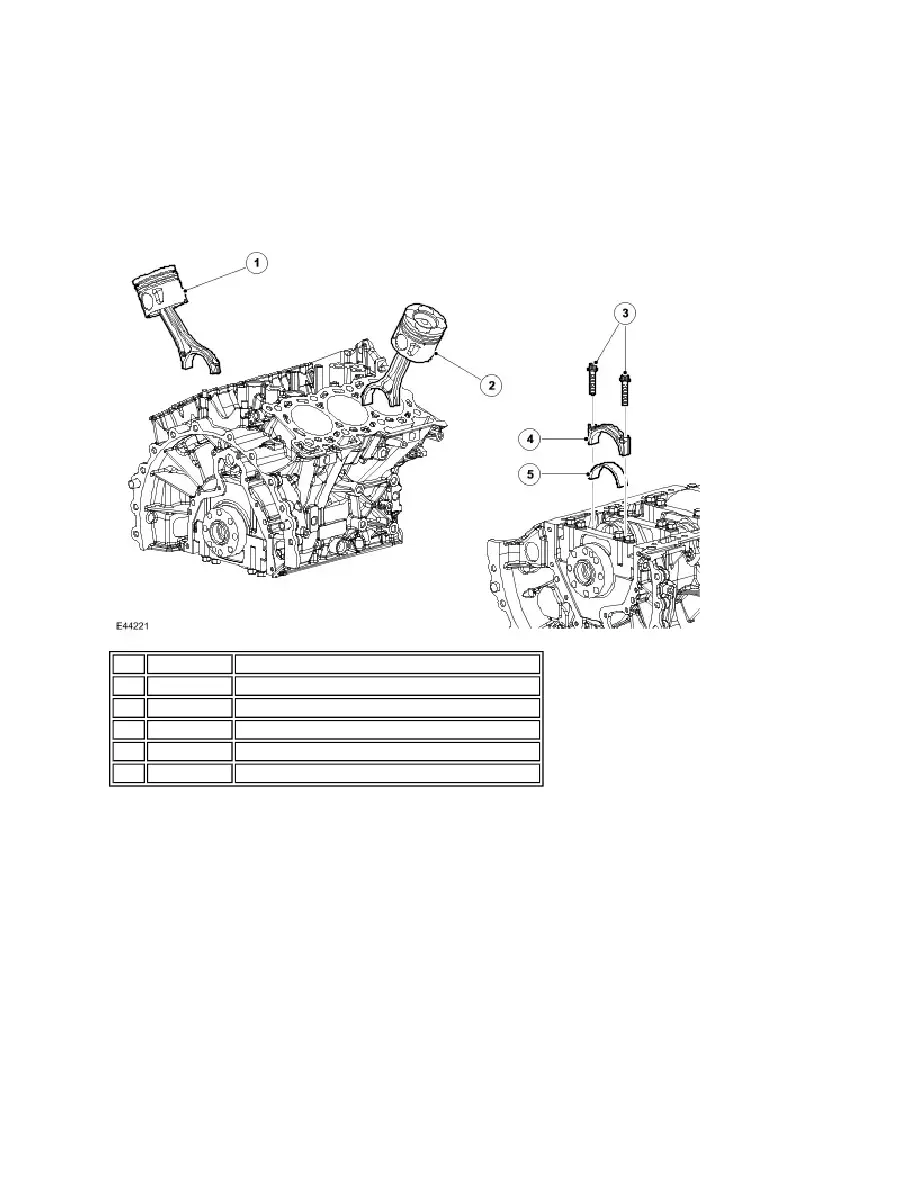

Item Part Number

Description

1

-

Piston and connecting rod assembly, cylinders 4-6

2

-

Piston and connecting rod assembly, cylinders 1-3

3

-

Bolts

4

-

Connecting rod bearing cap

5

-

Connecting rod lower bearing