LR3/Disco 3

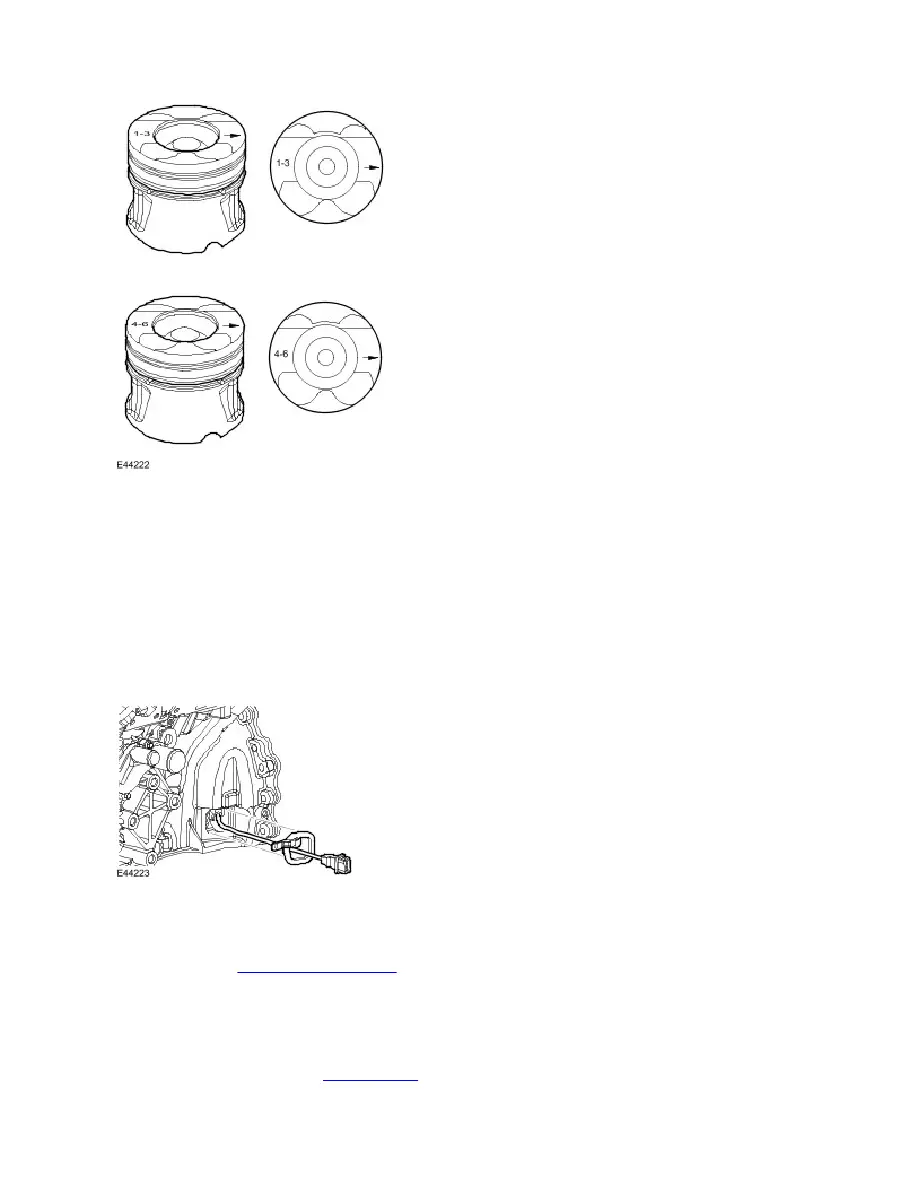

When installing pistons ensure the arrows on the piston crowns all point to the front of the engine and the pistons are

located in the correct cylinder banks, i.e. cylinders 1, 2, 3 or cylinders 4, 5, 6.

NOTE :

The piston top ring is a taper type and is fitted with the taper to the top of the piston. All rings marked 'top' are assembled

with 'top' uppermost. All rings must be spaced evenly around the piston before installing. The circumference gap of the

double bevelled oil control ring must be opposite the spiral control joint.

Crankshaft Position Sensor

The Crankshaft Position (CKP) sensor is located at the rear of the crankshaft, behind the flywheel in the LH side of the

rear oil seal retainer. The sensor provides an input of engine crankshaft speed and position. The sensor works on the

principle of the Hall effect and scans a trigger wheel (magnetic disc) on the crankshaft. An air gap of 0.4 to 1.5mm,

between the trigger wheel and the CKP sensor, is achieved by the positional mounting of the sensor. For additional

information, refer to

Electronic Engine Controls

(303-14C Electronic Engine Controls - 2.7L Diesel)

Starter Motor

The engine starter motor is installed at the rear RH side of the ladder frame, at the cylinder block to ladder frame split line.

For additional information, refer to

Starting System

(303-06C Starting System - 2.7L Diesel)

All pistons are common single grade/single part number for all engines.