LR3/Disco 3

solenoid operated valve which is closed when de-energised. The valve is controlled by the Engine Control Module (ECM)

and is operated when engine operating conditions are correct to allow purging of the charcoal canister.

The purge valve is Pulse Width Modulated (PWM) at 10Hz by the ECM. At this high frequency the pulses of purge gas

flowing into the inlet manifold are almost a continuous flow. The valve operates between 5% and 100% duty or mark

space ratio (% open time).

The ECM waits until the engine is running above 40°C (104°F) coolant with closed loop fuel operational. Under these

conditions the engine should be running smoothly with no warm up enrichment. The purge valve duty (and flow) is initially

ramped slowly because the vapor concentration is unknown (a sudden increase in purge could cause the engine to flood).

The concentration is then determined from the amount of adjustment that the closed loop fuelling is required to make to

achieve the target Air Fuel Ratio (AFR). Once the concentration has been determined, the purge flow can be increased

rapidly and the injected fuel can be proactively adjusted to compensate for the know purge vapor and the target AFR

control is maintained.

When the purging process is active, fresh air is drawn into the charcoal canister via the DMTL pump atmospheric vent

connection and its filter on NAS vehicles and via the atmospheric vent hose connection and the spider trap on non NAS

vehicles.

On NAS vehicles the system does not include a pressure test point. Pressure testing of the purge valve hose is achieved

by disconnecting the purge valve joint on the underside of the vehicle, forward of the fuel tank and connecting a special

tool to allow the system to be pressure tested. The test performs a pressure test on the purge hose connection forward of

the fuel tank back to the charcoal canister. The special tool is then connected to the purge hose connection forward of the

fuel tank to perform a pressure test on the purge hose to the purge valve.

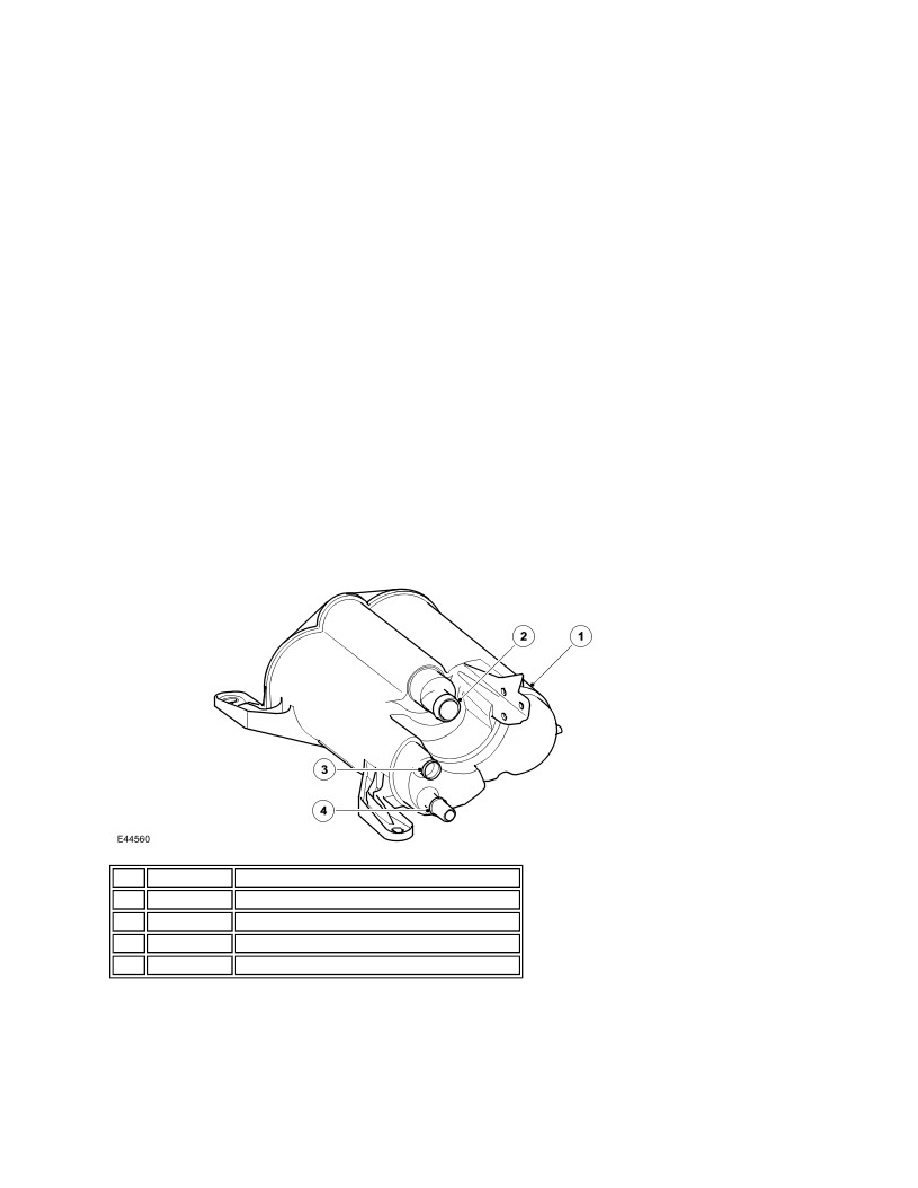

CHARCOAL CANISTER

Charcoal Canister - All except NAS

Charcoal Canister - NAS

Item Part Number

Description

1

-

Charcoal canister

2

-

Charcoal canister atmospheric vent connection

3

-

Purge hose connection

4

-

Charcoal canister tank vent connection