LR3/Disco 3

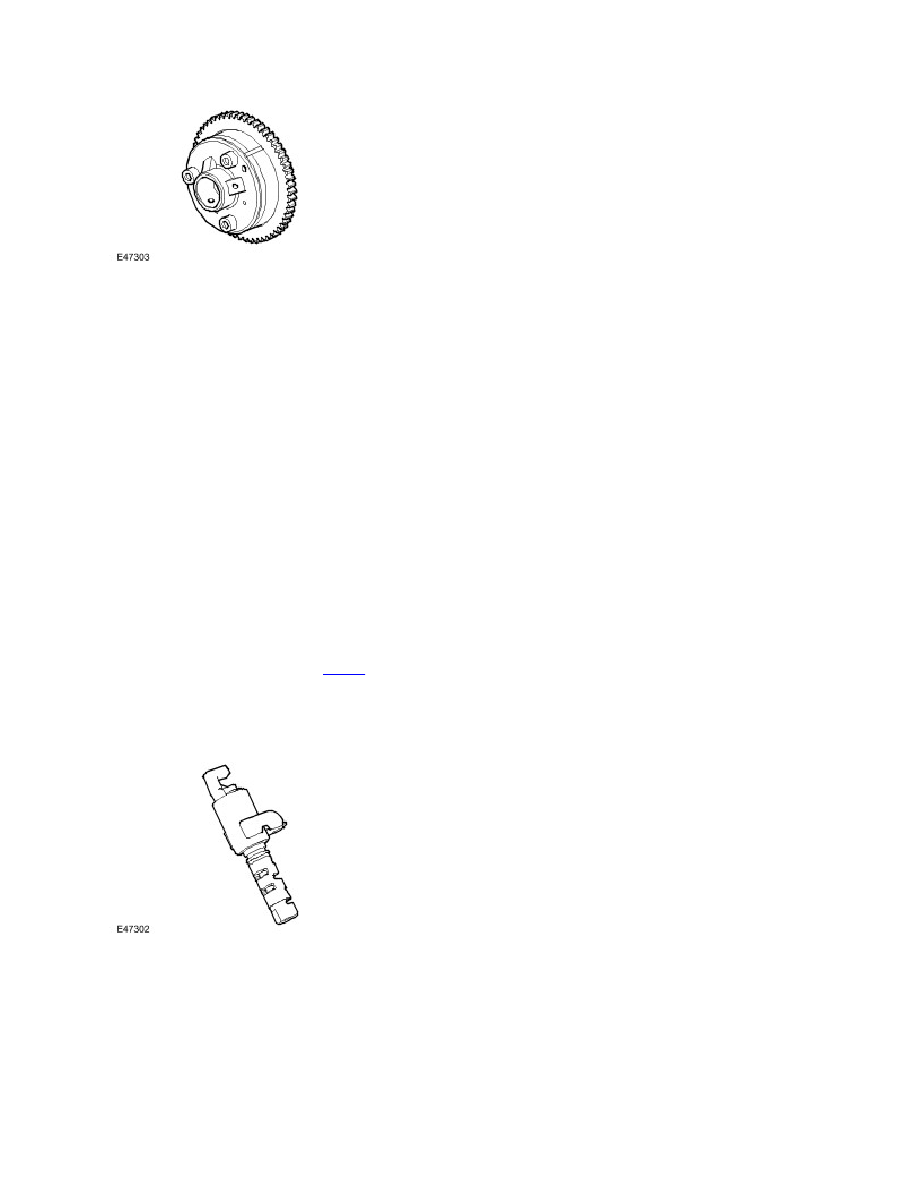

The VVT unit is a hydraulic actuator mounted on the end of the inlet camshaft. The unit advances or retards the camshaft

timing to alter the camshaft to crankshaft phase. The ECM controls the VVT timing unit via a oil control solenoid. The oil

control solenoid routes oil pressure to the advance or retard chambers either side of the vanes within the VVT unit.

The VVT unit is driven by the primary drive chain and rotates relative to the exhaust camshaft. When the ECM requests a

retard in camshaft timing the oil control solenoid is energised which moves the shuttle valve in the solenoid to the relevant

position allowing oil pressure to flow out of the advance chambers in the VVT unit whilst simultaneously allowing oil

pressure into the retard chambers.

The ECM controls the advancing and retarding of the VVT unit based on engine load and speed. The ECM sends an

energise signal to the oil control solenoid until the desired VVT position is achieved. When the desired VVT position is

reached, the energising signal is reduced to hold the oil control solenoid position and consequently desired VVT position.

This function is under closed loop control and the ECM can sense any variance in shuttle valve oil pressure via the

camshaft position sensor and can adjust the energising signal to maintain the shuttle valve hold position.

VVT operation can be affected by engine oil temperature and properties. At very low oil temperatures the movement of

the VVT mechanism will be slow due to the high viscosity of the oil. While at high oil temperatures the low oil viscosity

may impair the VVT operation at low oil pressures. The oil pump has the capacity to cope with these variations in oil

pressure while an oil temperature sensor is monitored by the ECM to provide oil temperature feedback. At extremely high

oil temperatures the ECM may limit the amount of VVT advance in order to prevent the engine from stalling when

returning to idle speed.

VVT does not operate when engine oil pressure is below 1.25 bar. This is because there is insufficient pressure to release

the VVT units internal stopper pin. This occurs when the engine is shut down and the VVT unit has returned to the

retarded position. The stopper pin locks the VVT unit to the camshaft to ensure camshaft stability during the next start up.

For additional information, refer to

Engine

(303-01B Engine - 4.4L)

Valve Timing Solenoid

Valve Timing Solenoid

The valve timing solenoid controls the position of the shuttle valve in the bush carrier. A plunger on the solenoid extends

when the solenoid is energised and retracts when the solenoid is de-energised.

When the valve timing solenoids are de-energised, the coil springs in the bush carriers position the shuttle valves to

connect the valve timing units to drain. In the valve timing units, the return springs hold the ring pistons and gears in the

retarded position. When the valve timing solenoids are energised by the ECM, the solenoid plungers position the shuttle

valves to direct engine oil to the valve timing units. In the valve timing units, the oil pressure overcomes the force of the

return springs and moves the gears and ring pistons to the advanced position. System response times are 1.0 second