LR3/Disco 3

Misfire Detection

Legislation requires that the ECM must be able to detect the presence of an engine misfire. It must be able to detect

misfires at two separate levels. The first level is a misfire that could lead to the vehicle emissions exceeding 1.5 times the

Federal Test Procedure (FTP) requirements for the engine. The second level is a misfire that may cause catalyst damage.

The ECM monitors the number of misfire occurrences within two engine speed ranges. If the ECM detects more than a

predetermined number of misfire occurrences within either of these two ranges, over two consecutive journeys, the ECM

will record a fault code and details of the engine speed, engine load and engine coolant temperature. In addition, the ECM

monitors the number of misfire occurrences that happen in a 'window' of 200 engine revolutions. The misfire occurrences

are assigned a weighting according to their likely impact on the catalysts. If the number of misfires exceeds a certain

value, the ECM stores catalyst-damaging fault codes, along with the engine speed, engine load and engine coolant

temperature.

The signal from the crankshaft position sensor indicates how fast the poles on the flywheel are passing the sensor tip. A

sine wave is generated each time a pole passes the sensor tip. The ECM can detect variations in flywheel speed by

monitoring the sine wave signal supplied by the crankshaft position sensor.

By assessing this signal, the ECM can detect the presence of an engine misfire. At this time, the ECM will assess the

amount of variation in the signal received from the crankshaft position sensor and assigns a roughness value to it. This

roughness value can be viewed within the real time monitoring feature, using T4. The ECM will evaluate the signal

against a number of factors and will decide whether to count the occurrence or ignore it. The ECM can assign a

roughness and misfire signal for each cylinder, (i.e. identify which cylinder is misfiring).

T4 Diagnostics

The ECM stores faults as Diagnostic Trouble Codes (DTC), referred to as 'P' codes. The 'P' codes are defined by OBD

legislation and, together with their associated environmental and freeze frame data, can be read using a third party scan

tool or T4. T4 can also read real time data from each sensor, the adaptive values currently being employed and the

current fuelling, ignition and idle settings.

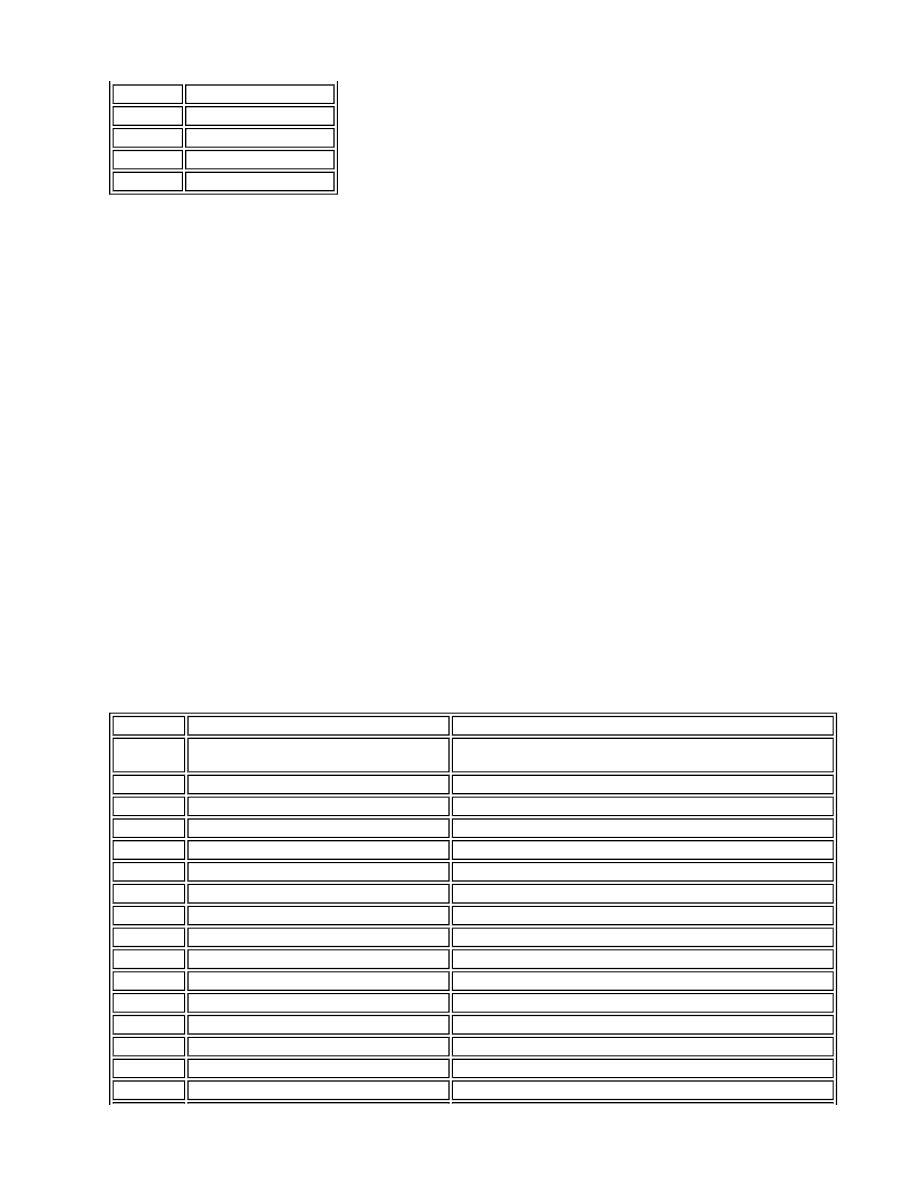

Adaptions Engine Speed, rev/min

1

1800 - 3000

2

3001 - 3800

3

3801 - 4600

4

4601 - 5400

P Code No

Component/ Signal

Fault Description

P0011

CMP/CKP/VVT

Bank A CMP/CKP Position error high , VVT retard position

high

P0012

CMP/CKP/VVT

Bank A CMP/CKP Position error low, VVT retard position low

P0021

CMP/CKP/VVT

Bank B CMP/CKP Position error, VVT retard position high

P0022

CMP/CKP/VVT

Bank B CMP/CKP Position error low , VVT retard position low

P0026

VVT

Bank A circuit malfunction range high/ low

P0028

VVT

Bank B circuit malfunction range high/ low

P0031

UHEGO

Bank A heater control circuit low

P0032

UHEGO

Bank A heater control circuit high

P0051

UHEGO

Bank B heater control circuit low

P0052

UHEGO

Bank B heater control circuit high

P0069

HAC

Sensor circuit/range performance

P0071

Ambient air temperature sensor

Range performance

P0072

Ambient air temperature sensor

Circuit low input

P0073

Ambient air temperature sensor

Circuit high input

P0075

VVT

Bank A open circuit

P0076

VVT

Bank A short to ground