LR3/Disco 3

attached to the front end of the transmission via 3 bolts. These bolts are asymmetrically positioned to ensure correct

angular location of the slave cylinder, which is also spigot-mounted for positional fit. In its free condition the slave cylinder

is fully extended, but it positions itself automatically as the clutch housing is fitted to the engine. The assembly requires no

setting or adjustment.

CLUTCH COVER ASSEMBLY

The clutch cover assembly is known as a self-adjusting clutch with a nominal diameter of 260mm.

Self Adjusting Clutch

The self-adjusting clutch contains a mechanism, which improves operation and driver comfort by enabling a more

consistent pedal load as the friction faces wear, unlike conventional types of clutch which exhibit increasing pedal load

with wear.

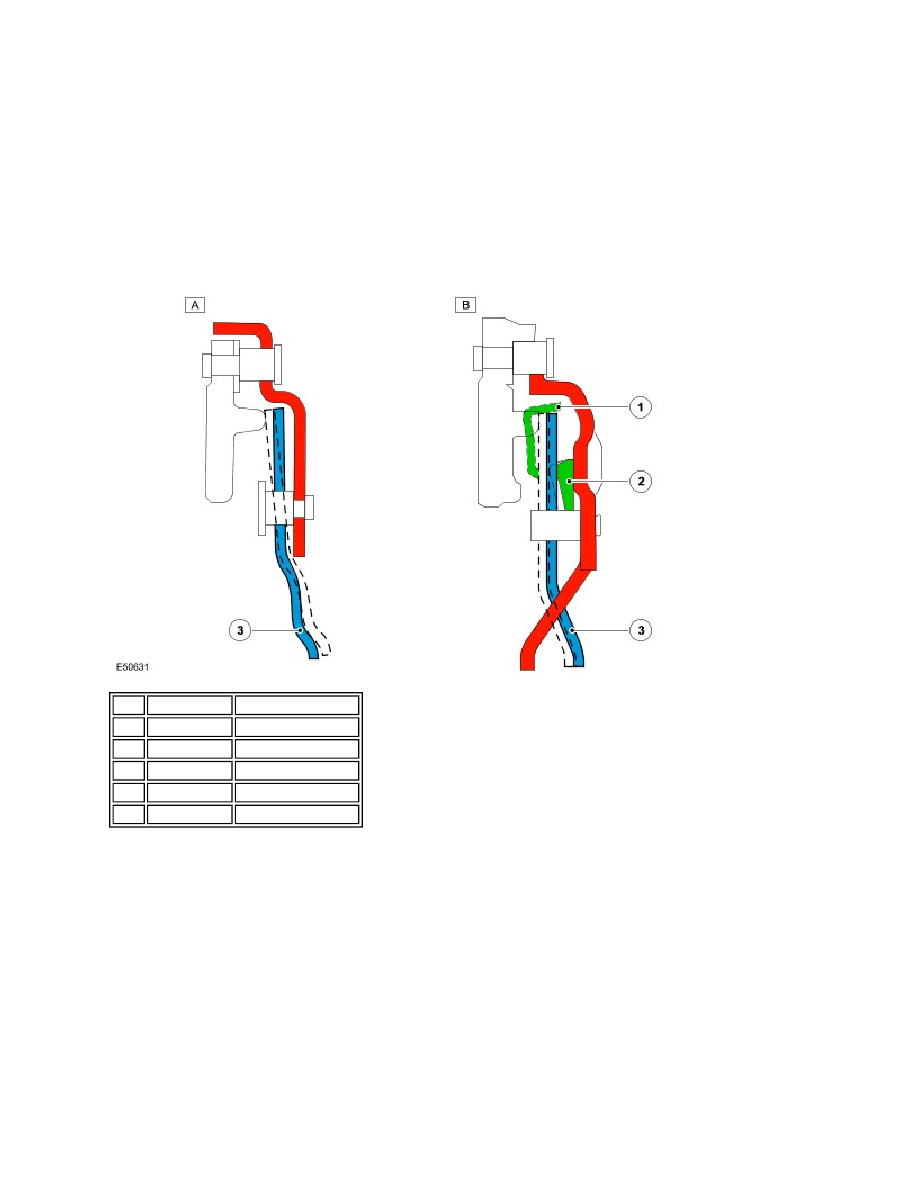

With a conventional clutch, facing wear causes the angle of the actuating diaphragm spring to change as the pressure

plate moves axially towards the engine, requiring a greater force to operate the clutch (diaphragm actuating force varies

with diaphragm angle). The self-adjusting clutch reduces this problem by allowing the diaphragm spring to follow the axial

movement of the pressure plate thus maintaining the diaphragm spring at the same angle throughout the life of the clutch.

As well as maintaining a more consistent pedal load, the clamp force on the pressure plate also remains constant with

wear.

The diaphragm spring is not fixed at its rotation point like the conventional system but pivots between a sensor spring and

an adjuster ring. The sensor spring provides a counter force, which is just sufficient to retain the diaphragm spring axially

against the cover via the adjuster ring and during normal actuation of the clutch. As the linings wear, the tendency of the

diaphragm angle to change causes an increase in the actuation force required to operate the clutch. When this increased

effort exceeds the counter force of the sensor spring, the diaphragm spring moves axially towards the pressure plate until

the original angle is restored. At this point the actuation force required drops to the level of the opposing sensor spring

Item Part Number

Description

A

-

Conventional clutch

B

-

Self adjusting clutch

1

-

Sensor spring

2

-

Adjuster ring

3

-

Diaphragm spring