LR3/Disco 3

to the sliding sleeve guided by the synchroniser body. The sliding sleeve is moved from the neutral position towards the

free-wheeling gear and, once synchronisation is complete, connects the free-wheeling gear to the main and/or layshafts.

INTERLOCK

The interlock prevents the simultaneous engagement of several gears.

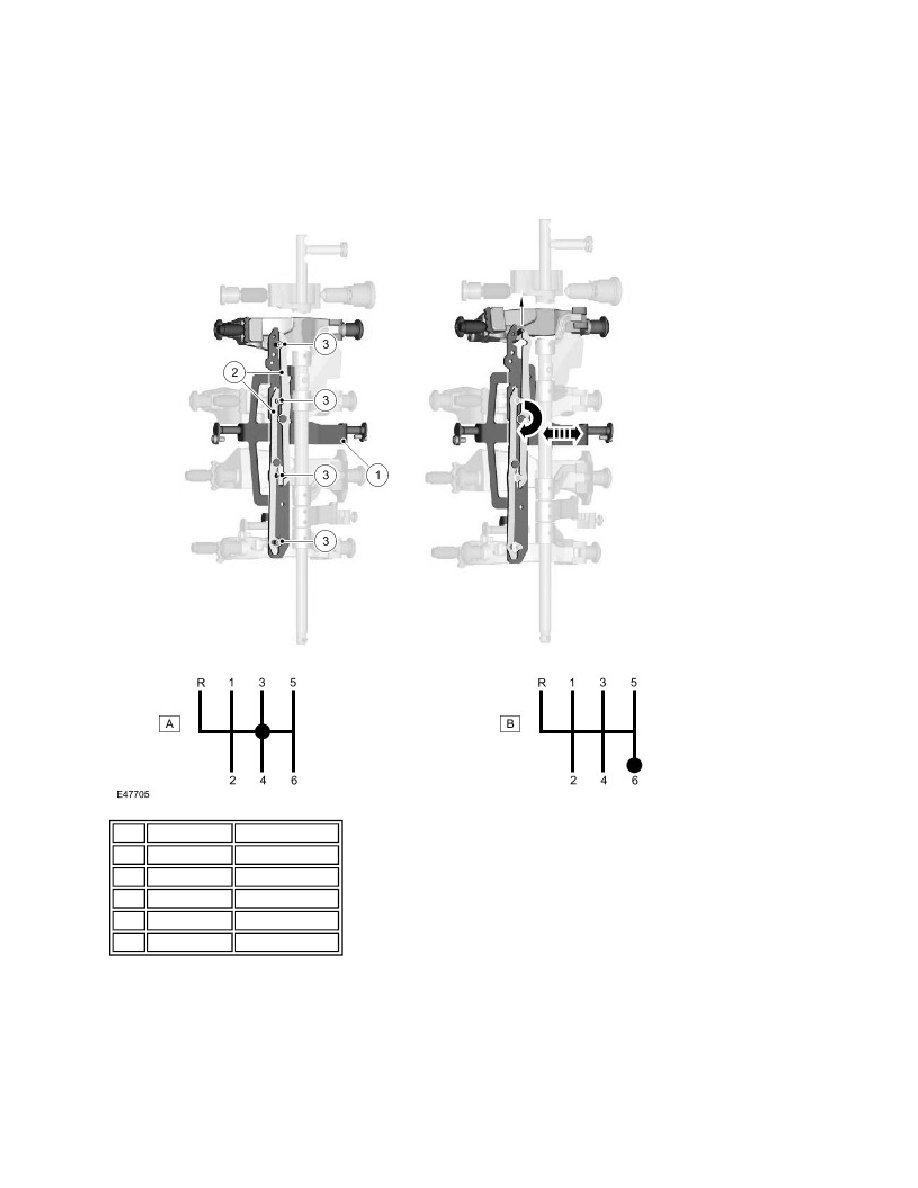

Two locking levers, attached to a locking bracket, control the interlock. The locking system works passively, i.e. the

locking mechanism is actuated through the swing fork motion itself. The swing forks are therefore designed with locking

pins.

During gear engagement, the locking levers are turned by the locking pins on the swing forks in the direction of the

selected gear and the locking bracket is shifted axially. The shifted swing fork remains moveable and all other swing forks

are fixed in place by their respective locking pins and the recesses at the locking levers and/or locking bracket.

Item Part Number

Description

A

-

Neutral position

B

-

6th gear position

1

-

Locking bracket

2

-

Locking lever

3

-

Locking pins