LR3/Disco 3

basic adjustment).

Check the dimensions of the measuring/mounting points.

Straightening: NOTE :

A body is always straightened in the opposite direction to that of the impact. Always carry out straightening repairs

with the complete body shell assembled (do not cut out any parts beforehand). Carry out the straightening work in

several stages. This prevents the risk of over stretching or of welded joints tearing out. During the individual

straightening steps, relieve tension by striking with an aluminium hammer while the part is subjected to a tensile

load (in the area of pre-determined folding points, dents, welded joins etc.).

NOTE :

A body is always straightened in the opposite direction to that of the impact. Always carry out straightening

repairs with the complete body shell assembled (do not cut out any parts beforehand). Carry out the

straightening work in several stages. This prevents the risk of over stretching or of welded joints tearing

out. During the individual straightening steps, relieve tension by striking with an aluminium hammer while

the part is subjected to a tensile load (in the area of pre-determined folding points, dents, welded joins

etc.).

Panel Beating

Fundamentals of panel beating

Before carrying out any sectional replacements or complete replacements of body panels, always check carefully

whether the damaged panel(s) can be rectified by panel beating.

Panel beating is usually the easiest and most economical method of repairing a damaged panel.

Examples of applications of different panel beating techniques:

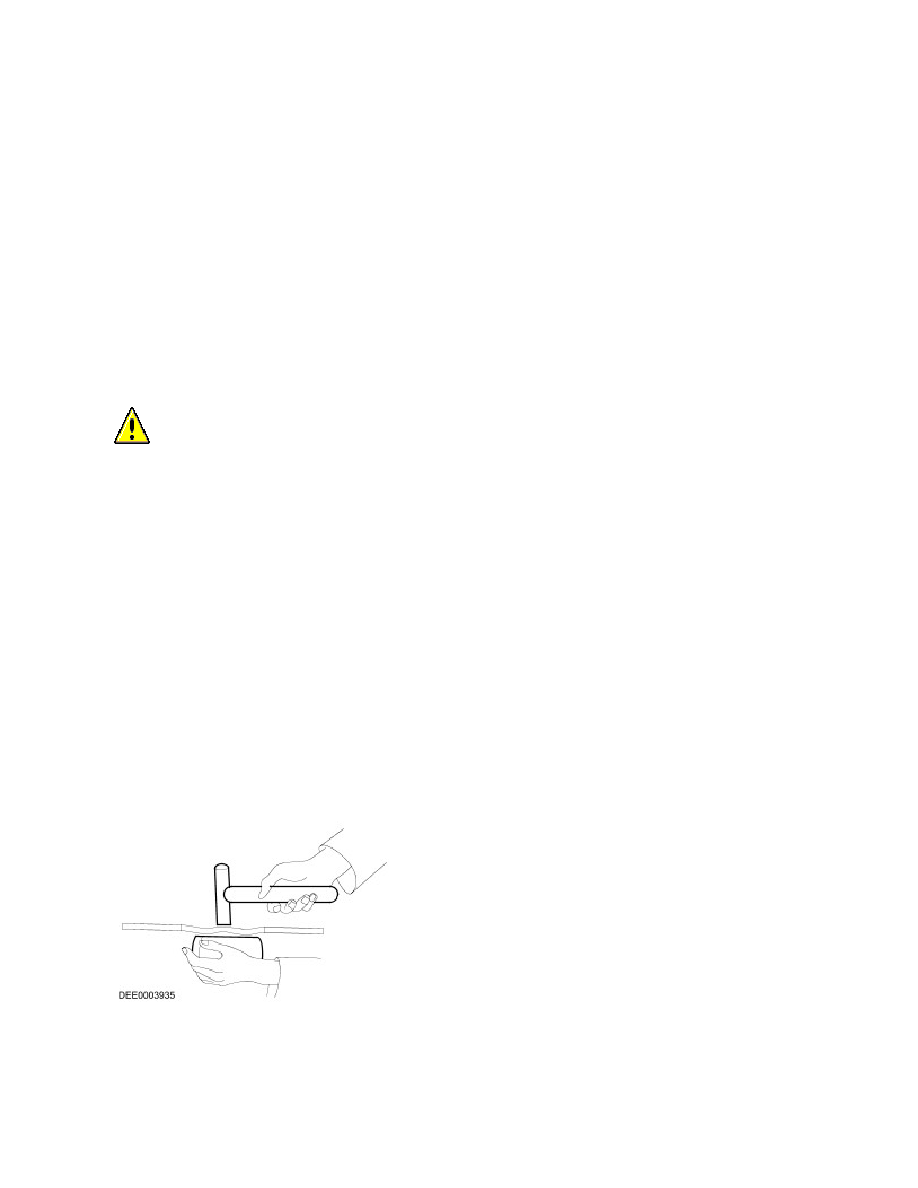

Aluminium hammer and mallet Advantage: Low risk of overstretching the panel. Used for repairs of small dents on

panels that are accessible from both sides. These two panel beating tools are usually used for "finishing repairs".

Advantage: Low risk of overstretching the panel.

Used for repairs of small dents on panels that are accessible from both sides.

These two panel beating tools are usually used for "finishing repairs".

Fine straightening with an aluminium hammer and a universal dolly

Sliding hammer If the damaged panel is only accessible from the outside, use a sliding hammer to pull it back into

shape. The discs or studs needed to mount the sliding hammer are welded onto the bare surface. Dents in the

panel can be flattened out using controlled application of the sliding hammer.

If the damaged panel is only accessible from the outside, use a sliding hammer to pull it back into shape.

The discs or studs needed to mount the sliding hammer are welded onto the bare surface. Dents in the

Check dimensions and gaps continuously during straightening.

Check dimensions and gaps continuously during straightening.

CAUTION : Ultra High Strength steel in the A-Pillar, B-Pillar and cantrail cannot be straightened.