LR3/Disco 3

are co-ordinated.

Equipment: Set up the equipment as directed by the manufacturer. The hoses must be untwisted. The core must

be free of abraded rod particles. The gas and current nozzles must be free of slag and scale residue. Pay

attention to the quality of the welding wire and the throughput of gas.

Set up the equipment as directed by the manufacturer.

The hoses must be untwisted.

The core must be free of abraded rod particles.

The gas and current nozzles must be free of slag and scale residue.

Pay attention to the quality of the welding wire and the throughput of gas.

Body: Ensure that the joint surface is correct. Prepare a bare metal joint surface. Maintain the correct gaps

(formation of roots).

Ensure that the joint surface is correct.

Prepare a bare metal joint surface.

Maintain the correct gaps (formation of roots).

Notes on technique/method: NOTE :

NOTE :

Attach the ground cable right next to the welding point (ensure that good contact is made). During plug welding

start welding on the lower panel to ensure adequate penetration.

NOTE :

NOTE :

Attach the ground cable right next to the welding point (ensure that good contact is made).

During plug welding start welding on the lower panel to ensure adequate penetration.

Plug welding

Bonded glazing

The windscreen, side and rear windows are bonded directly onto the window frames on the body and

liftgate.

The windows are bonded primarily for reasons of adhesive strength. Bonded glazing provides additional

torsional stiffness to the body.

The increased application of heat during MIG welding destroys the welding primer/zinc layer over a much

larger area than during resistance spot welding, as a result of which much more care needs to be taken

when applying anti-corrosion protection afterwards.

A test weld should always be carried out to ensure that the welded joint is not just a surface connection.

The increased application of heat during MIG welding destroys the welding primer/zinc layer over a

much larger area than during resistance spot welding, as a result of which much more care needs to

be taken when applying anti-corrosion protection afterwards.

A test weld should always be carried out to ensure that the welded joint is not just a surface

connection.

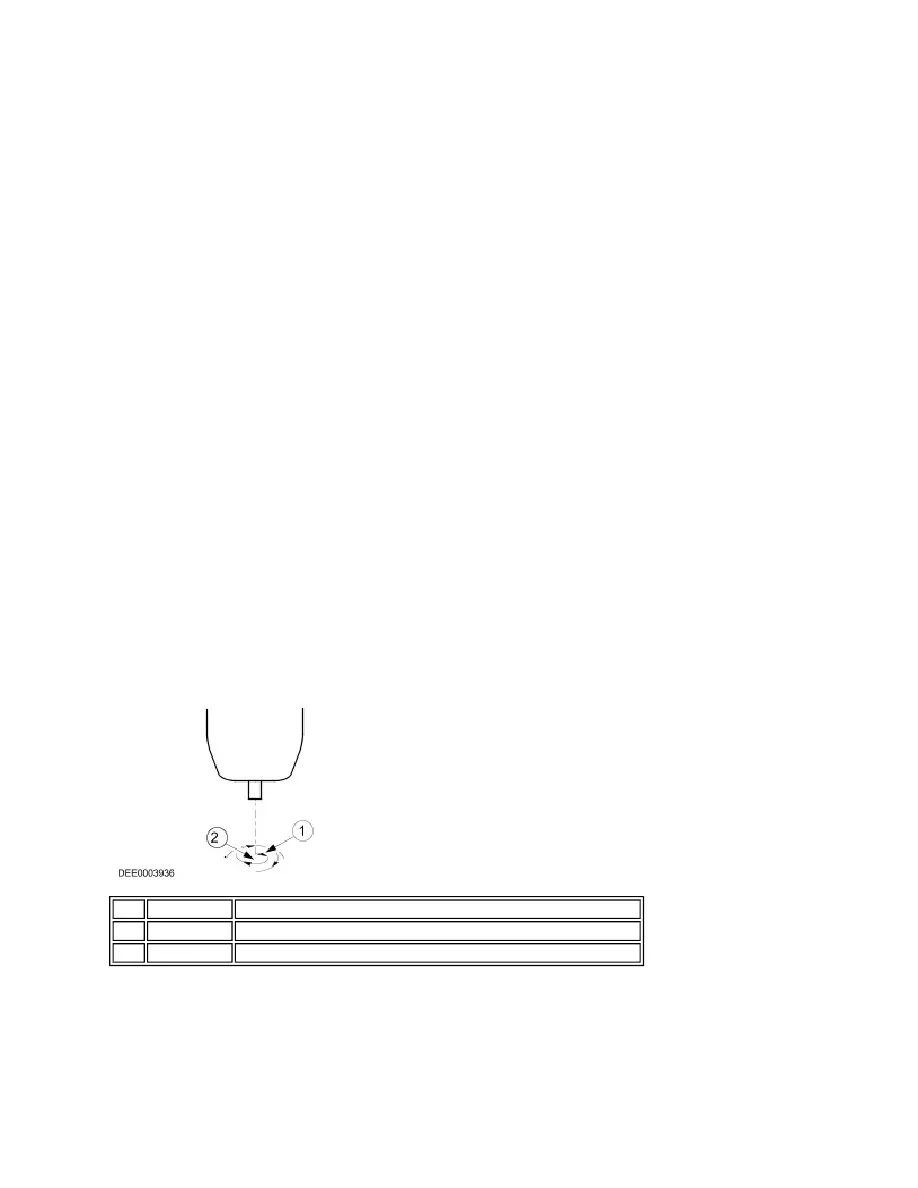

Item Part Number

Description

1

Welding direction: circular pattern working from the inside outwards

2

Welding starting point: centre of hole on lower panel