LR3/Disco 3

Clean and prime all internal areas and those to be sealed.

NOTE :

Partial renewal

The procedure to follow when partially renewing components is the same as described in the section "Welded

components".

The main difference when components are partially, rather than completely renewed, concerns the preparation of butt or

lap joints.

When bodywork components are cut through, attention must be paid to the adequate removal of the paint and

zinc coatings on inner areas. This specially applies to areas which are difficult to access internally.

It is important for the weld quality that the inner area is bare metal. Zinc and paint residues in the weld area burn

and cause serious hole formation during welding.

If the zinc layer and the paint coating are not removed, the zinc and paint will burn during welding. The soot

produced prevents satisfactory cavity protection.

Procedure

The paint layer must be removed for a width of 30mm from the line of the weld using a rotating tress wire brush.

This operation must be carried out on both the new and the old parts of the bodywork.

Depending on the bodywork component, a 10mm width of the underlying zinc layer must also be removed along

the weld line.

NOTE :

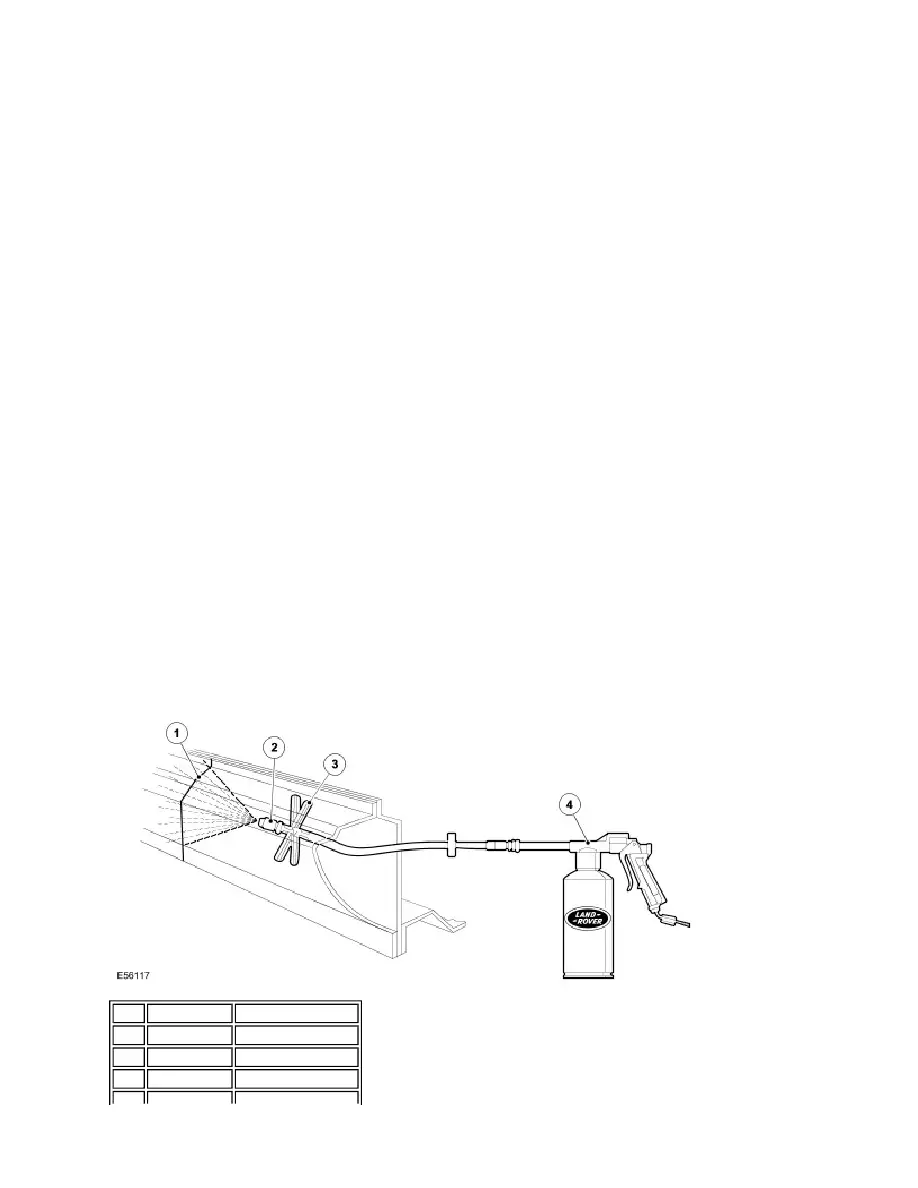

Application of cavity wax protection on a door rocker panel after partial repair

The primer must be dry before sealing mastic or underbody protection is applied. Do not use thinners when

applying sealing mastic (the mastic would not dry).

A flat scraper or a wire brush can be used instead of the rotating brush if the cavity is small. Do not use an angle

grinder, which would weaken the structure.

Item Part Number

Description

1

-

Weld bead

2

-

Spray head

3

-

Distance maintainer