LT230 Transfer Box Overhaul - Intermediate Gears

TRANSFER BOX

OVERHAUL

45

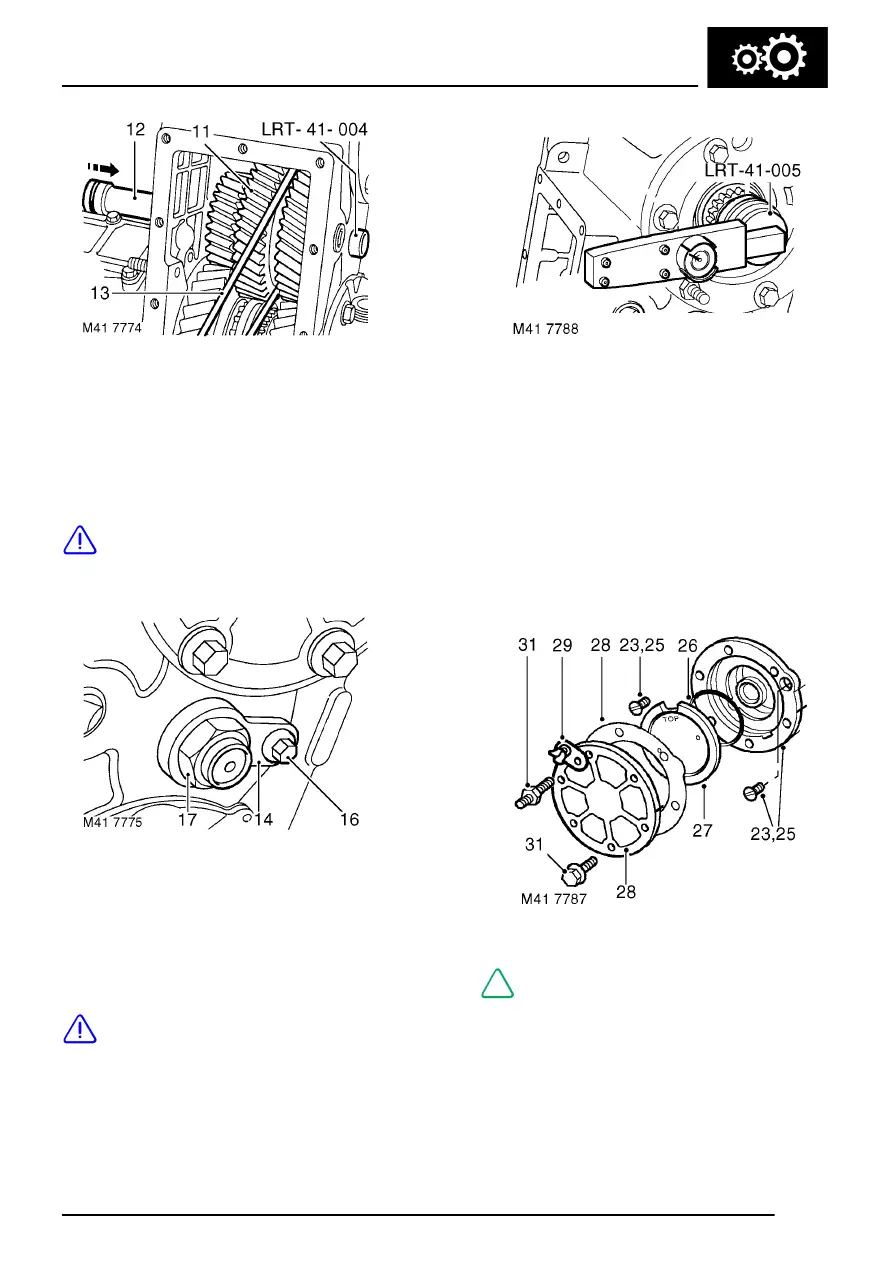

11. Raise intermediate gears until dummy shaft

LRT-41-004 can be inserted from front output

housing side of main casing.

12. Fit intermediate shaft, drift shaft into position

whilst at the same time expelling dummy shaft

LRT-41-004 .

CAUTION: Ensure ’O’ ring is not displaced

from main casing.

13. Remove wire from around intermediate gears.

14. Rotate intermediate shaft until retaining plate

can be located on flat on shaft.

15. Apply Loctite 290 to threads of retaining plate

bolt.

16. Fit bolt and tighten to 25 Nm (18 lbf.ft).

17. Fit a new intermediate shaft nut and tighten to

88 Nm (65 lbf.ft).

CAUTION: Do not stake nut at this stage.

18. Select neutral.

19. Screw a suitable bolt into tapped hole in end of

tool LRT-41-005 .

20. Insert tool LRT-41-005 in end of mainshaft.

21. Using a suitable torque meter on tool

LRT-41-005 , check torque to turn of transfer

box gear train :

Torque to turn = 2.2 Nm (19 lbf.in)

22. If torque to turn figure is incorrect, intermediate

gear bearing pre-load setting procedure must

be repeated. When torque to turn figure is

correct, remove tool LRT-41-005 and stake

flange of intermediate shaft nut into recess in

intermediate shaft.

NOTE: Discovery cover plate illustrated.

23. Up to serial no. 288709E: Fit and tighten 2

countersunk screws to secure mainshaft input

gear bearing housing.

24. Remove bolts used to temporarily secure

mainshaft input gear bearing housing.