LT230 Transfer Box

TRANSFER BOX

44

OVERHAUL

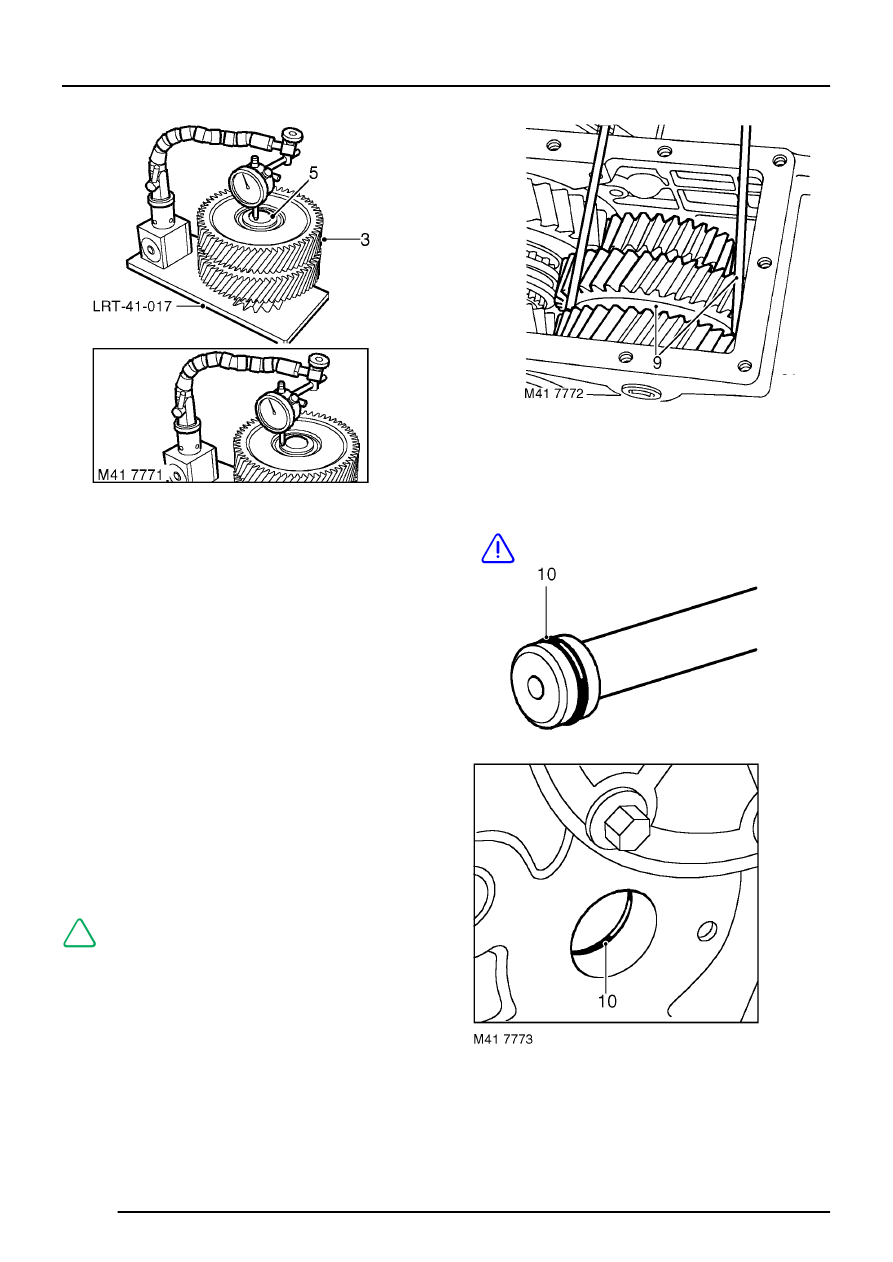

3. Fit bearing inner track ’A’ on to tool post

ofLRT-41-017 and position intermediate gears

on to bearing ’A.’

4. Fit bearing inner track ’B’ to intermediate

gears, apply finger pressure to bearing inner

tracks and rotate gears 5 to 10 turns to settle in

bearing rollers.

5. Attach a DTI to base of LRT-41-017, zero

gauge on top of tool post and take 2

measurements at 180

°

of the step height

between the top of the tool post and the inner

track of the bearing, take an average of the 2

readings and record this as measurement ’C’.

Measurement ’C’ should be in the range of

0.15 to 0.64mm (0.006 to 0.025in).

6. Using the formula 103.452mm (4.0729in) - ’A’ -

’B’ - ’C’ calculate the length of bearing spacer

required. From the result of the calculation

round DOWN to the nearest length of spacer

available to give a correct bearing pre-load of

0.05mm (0.002in).

NOTE: There are 40 selective spacers

available ranging in length from 58.325mm

(2.296in) to 59.300mm (2.335in) in

increments of 0.025mm (0.001in).

7. Remove intermediate gear assembly from

LRT-41-017.

8. Lubricate and fit bearings and selected spacer

to intermediate gears.

9. Wrap a suitable length of wire around

intermediate gears and using assistance, lower

gears into main casing ensuring that they are

meshing with input and differential gears.

CAUTION: Do not remove wire at this

stage.

10. Lubricate new ’O’ rings with recommended oil

and fit to intermediate shaft and main casing.