Range Rover P38

12

ENGINE

NEW RANGE ROVER

46

REPAIR

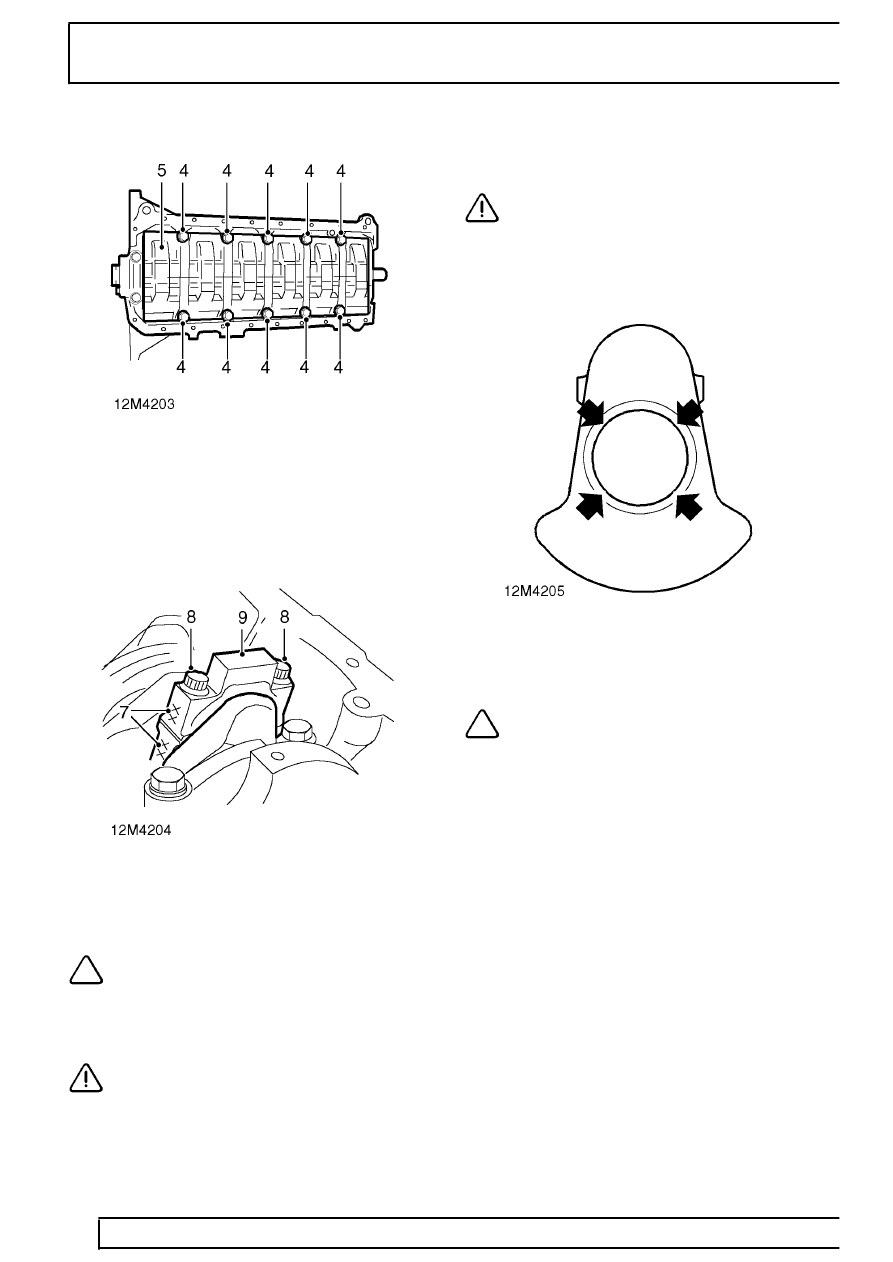

4. Progressively slacken then remove and discard

10 bolts securing reinforcing plate,

5. Remove reinforcing plate.

6. Carefully rotate crankshaft to gain access to

connecting rod bolts.

7. Ensure that connecting rods and big-end bearing

caps are suitably identified to each other.

8. Remove big-end bearing cap bolts.

NOTE: Do not discard bolts at this stage.

9. Remove big-end bearing caps, remove and

discard big-end bearing shells.

CAUTION: Dowel located, do not tap

bearing caps sideways.

10. Remove and discard big-end bearing shells from

connecting rods.

CAUTION: Take care when carrying out

above operation that piston does not

contact valves. Keep big-end bearing caps

and bolts in their fitted order.

Inspection

11. Measure and record crankshaft big-end journal

diameter, take 4 measurements at 90

°

intervals.

NOTE: There are 3 sizes of crankshaft

big-end journals, Standard, Size 1 and Size

2. Crankshafts with either Standard or Size

1 journals may be ground to the next undersize

and the appropriate oversize big-end bearing

shells fitted.

Standard = 44.975 to 45.00 mm (1.770 to 1.771 in)

Size 1 - 0.25 (0.01 in) undersize = 44.725 to 44.75

mm (1.761 to 1.762 in)

Size 2 - 0.50 mm (0.02 in) undersize = 44.475 to

44.50 mm (1.751 to 1.752 in)

12. Repeat above procedures for remaining big-end

journals.