Range Rover P38

BMW DIESEL

57

REPAIR

31. Using scale provided, measure width of

Plastigage on each main bearing journal and

compare with specified bearing clearances:

Main bearing clearance = 0.020 to 0.058 mm

(0.001 to 0.002 in)

32. If clearances are incorrect, select alternative

main bearing cap shell(s) from the range

available and repeat check.

NOTE: If colour coding of selected bearing

shell(s) differs from colour marked on

adjacent crankshaft web, ensure correct

colour is marked on web on completion.

33. Remove all traces of Plastigage using an oily

rag.

34. Fit selected main bearing shells to main bearing

caps.

35. Remove crankshaft, lubricate journals and main

bearing shells with engine oil.

Crankshaft end float - check

36. Fit crankshaft, fit main bearing caps ensuring

that reference marks are on exhaust manifold

side of engine.

37. Align main bearing caps to crankcase.

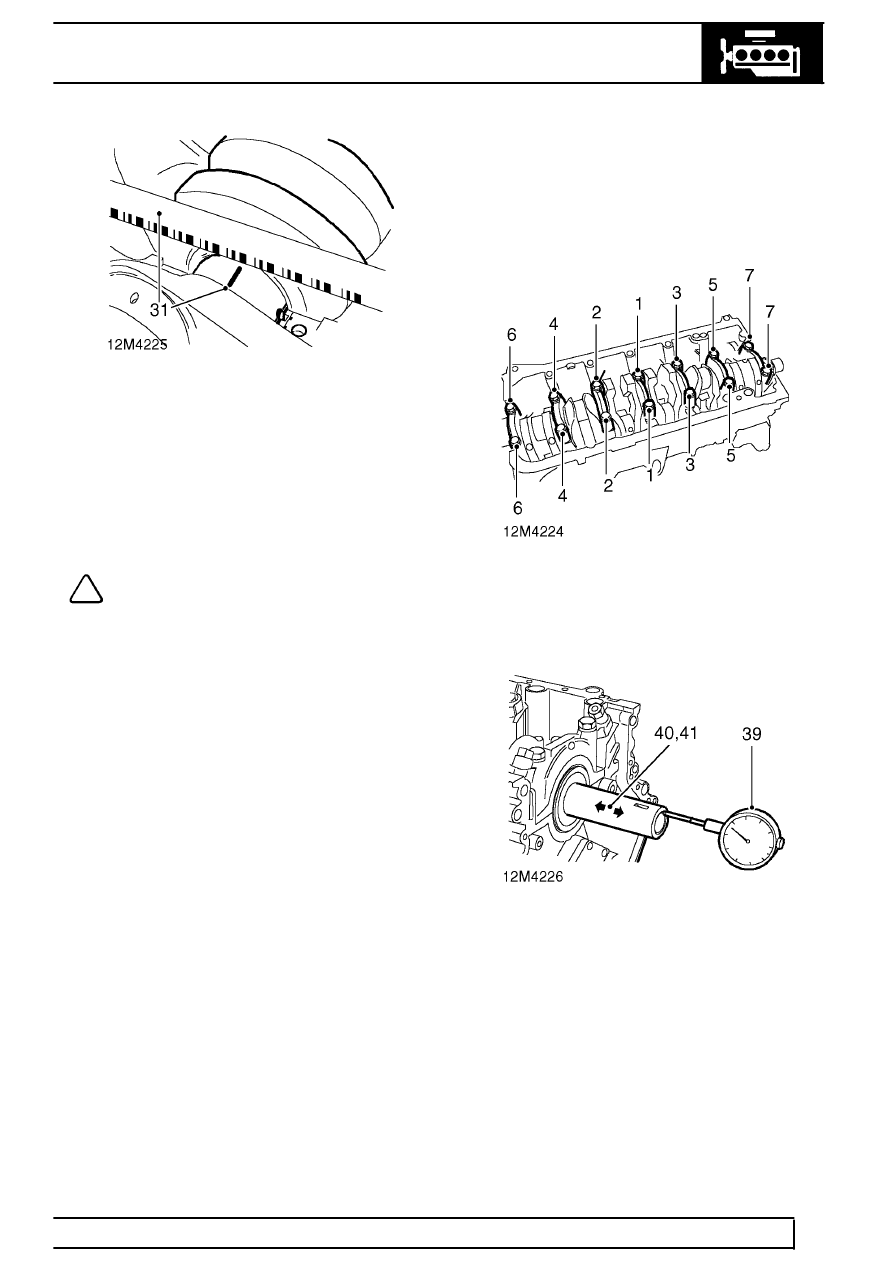

38. Fit original main bearing cap bolts and tighten in

sequence shown to

20 Nm (15 lbf.ft) then using

an angular torque wrench, tighten in sequence a

further 50

°

.

39. Position a suitable DTI to front of crankshaft.

40. Move crankshaft fully rearwards and zero gauge.

41. Move crankshaft fully forwards and note

end-float reading on gauge.

Crankshaft end-float = 0.080 to 0.163 mm (0.003

to 0.006 in)