Range Rover P38

12

ENGINE

NEW RANGE ROVER

58

REPAIR

Crankshaft end-float incorrect:

42. Remove crankshaft.

43. Select combined thrust/main bearing shells from

the range available to give correct end-float

ensuring that correct colour coding/size of

bearing shell is maintained.

NOTE: Each of the thrust/main bearing

shell sizes has three widths of shell

available:

Standard = 25.0 mm (0.94 in)

Size 1 = 25.2 mm (0.992 in)

Size 2 = 25.4 mm (1.00 in)

44. Fit selected thrust/main bearing shells in cylinder

block and main bearing caps.

45. Fit crankshaft and main bearing caps ensuring

that identification marks are on exhaust manifold

side of engine and repeat check as necessary

until end-float is correct.

46. Discard original main bearing cap bolts on

completion.

Crankshaft end-float correct:

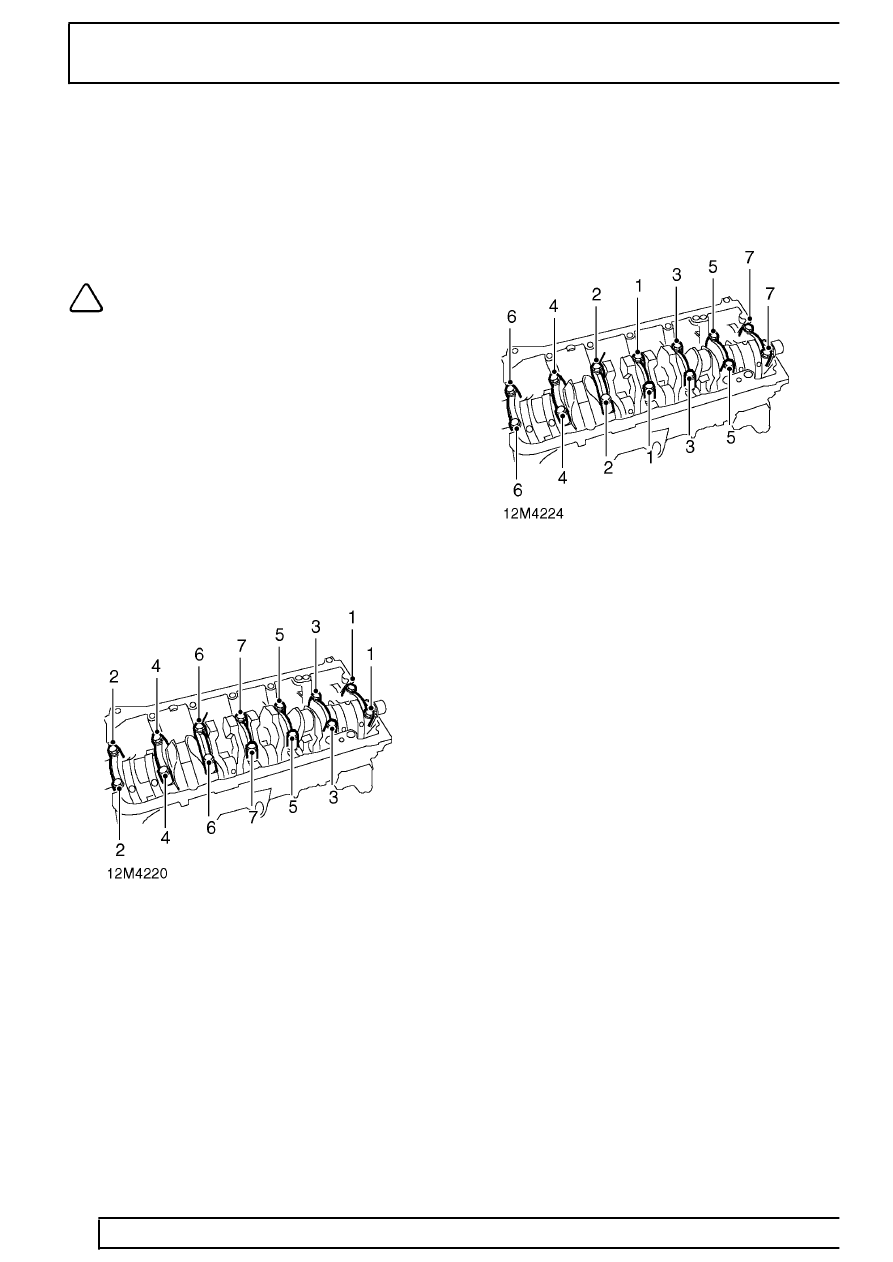

47. Using sequence shown, progressively slacken

then remove main bearing cap bolts; discard

bolts.

Refit

48. Lightly oil threads of new main bearing cap bolts.

49. Fit main bearing cap bolts, align main bearing

caps to crankcase.

50. Tighten main bearing cap bolts in sequence

shown using the following procedure:

Stage 1 - Tighten in sequence shown to

20 Nm

(15 lbf.ft).

Stage 2 - Slacken bolts on number 6 main

bearing cap.

Stage 3 - Using a hide mallet, strike each end of

crankshaft to centralise thrust/main bearing

shells.

Stage 4 - Tighten number 6 main bearing cap

bolts to

20 Nm (15 lbf.ft)

Stage 5 - Using an angular torque wrench,

tighten all main bearing cap bolts in sequence a

further 50

°

.

51. Fit pistons and connecting rods.

See this

section.

52. Fit crankshaft rear oil seal.

See this section.

53. Fit oil pump.

See this section.

54. Fit engine and gearbox.

See this section.