Range Rover P38

19

FUEL SYSTEM

NEW RANGE ROVER

4

DESCRIPTION AND OPERATION

Input devices

Input devices of the DDE system comprise the

following:

Crankshaft position sensor

Start of injection sensor

Fuel temperature sensor

Coolant temperature sensor

Intake air temperature sensor

Manifold absolute pressure sensor

Vehicle speed signal

Throttle position sensor

Servo unit potentiometer (drive potentiometer) on

quantity servo control unit

Clutch switch

Brake switches

Cruise control selector (if fitted)

Crankshaft position sensor (CKP sensor)

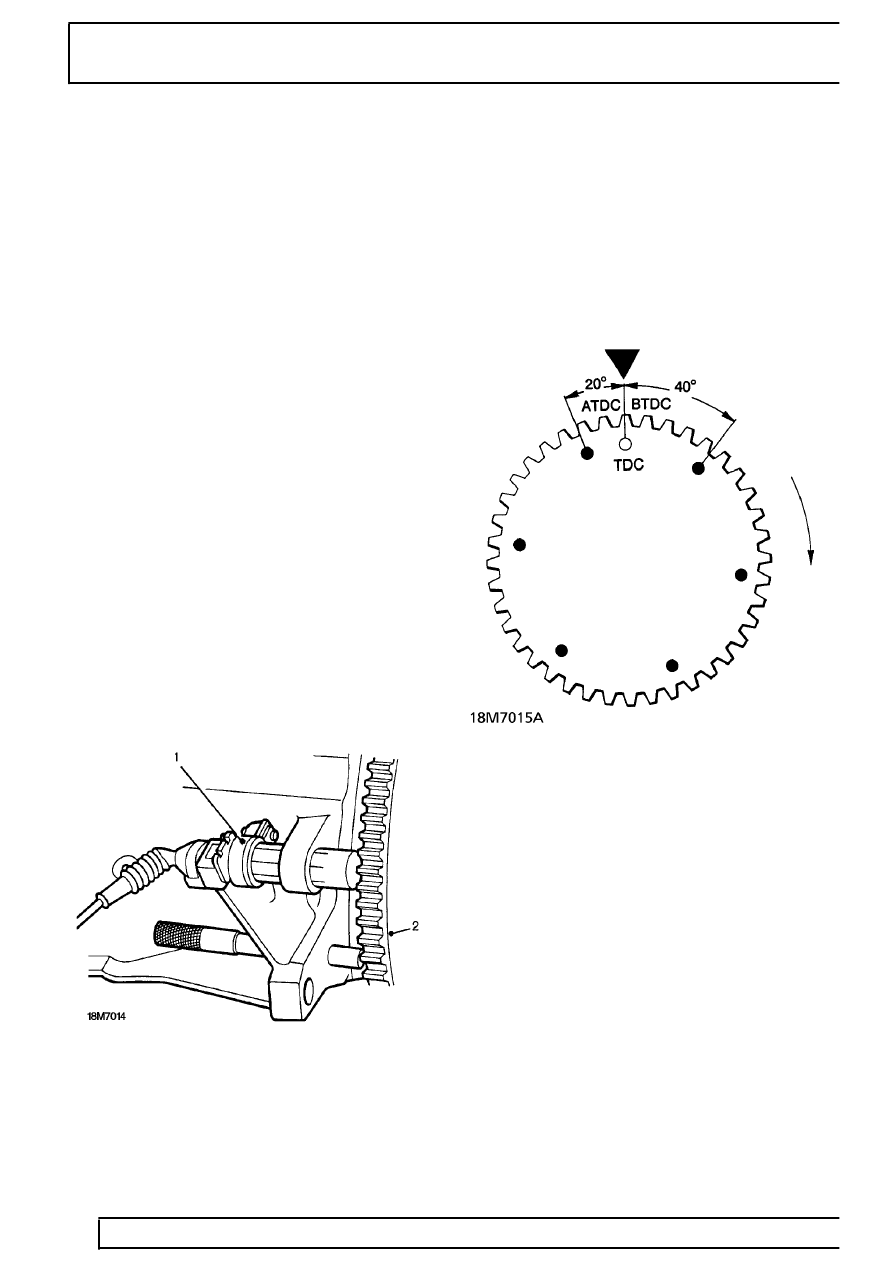

Attached to the flywheel of the engine are six position

pins. These are equally spaced around the crankshaft

circumference at 60 degree intervals.

To determine engine speed and crankshaft position,

an inductive CKP sensor is mounted on the crankcase

adjacent to the flywheel. The CKP sensor consists of

a body containing a coil and a permanent magnet

which provides a magnetic field. The CKP sensor is

situated so that an air gap exists between it and the

position pins. Air gap distance is critical for correct

operation.

1. Sensor

2. Flywheel

As the flywheel rotates, position pins pass the CKP

sensor and disturb the magnetic field, inducing

voltage pulses in the coil. The pulses are transmitted

to the ECM.

When the flywheel rotates one complete revolution,

six pulses are transmitted to the ECM. The ECM

determines engine speed by calculating how many

pulses occur within a given time. The output from the

CKP sensor is also used, in conjunction with the start

of injection sensor, to determine and control ignition

timing.

The flywheel position pins are spaced so that at TDC,

one pin is 40 degrees before TDC while the other is

20 degrees after TDC as shown. To determine which

pulse represents 40 degrees before, or 20 degrees

after TDC, the control unit requires additional

information from the start of injection sensor.