Range Rover P38

BMW DIESEL

5

DESCRIPTION AND OPERATION

Start of injection sensor

The start of fuel injection is registered by this sensor

which is incorporated in No 4 injector.

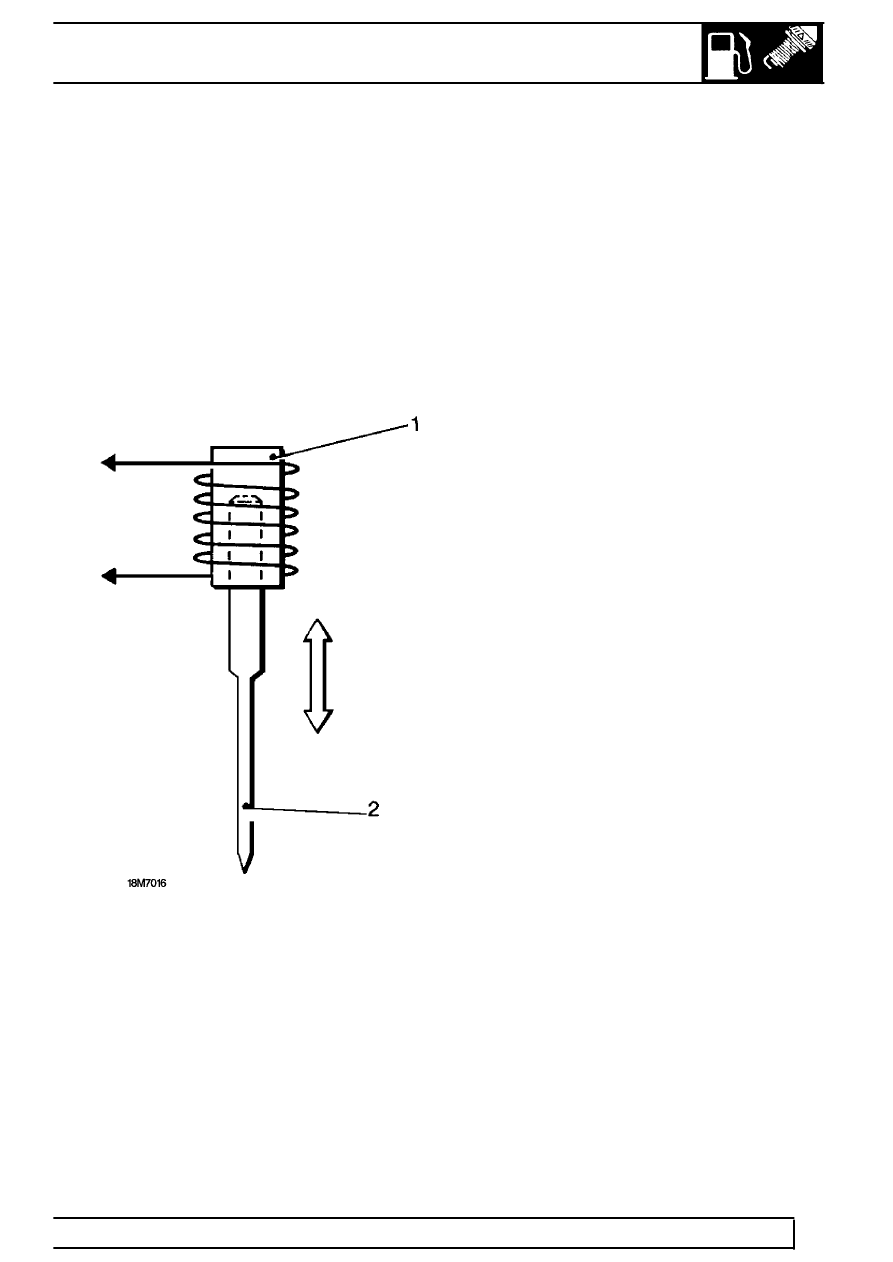

The sensor consists of a coil which surrounds the

shaft of an extended injection needle.The coil is fed a

DC supply from the ECM which produces a magnetic

field.

When the needle is moved under the influence of fuel

pressure, the magnetic field is disturbed which

induces an AC voltage in the coil. The induced voltage

is registered in the ECM as a reference point for the

start of injection.

1. Coil

2. Injector needle

The ECM uses the input signals from the start of

injection sensor, together with signals from the

crankshaft position sensor, to detect the actual start of

injection angle. The detected actual value is adjusted

by the ECM to a nominal value via the injection timing

solenoid.

Fuel temperature sensor

Fuel temperature is monitored by a sensor located in

the fuel injection pump. This sensor is of the negative

temperature coefficient (NTC) type, designed to

reduce its resistance with increasing temperature.

When the system is operating, the ECM regularly

checks the sensor resistance. As fuel density varies

with temperature, the information received is used to

calculate the correct quantity of fuel to inject.

Engine coolant temperature sensor (ECT sensor)

The temperature of the engine coolant is monitored by

a ECT sensor located on the cylinder head.

The ECT sensor is of the NTC type and is similar in

operation to the fuel temperature sensor previously

described.

The ECM uses this information to adjust the basic

injection timing and quantity values for all operating

conditions.