Range Rover P38

19

FUEL SYSTEM

NEW RANGE ROVER

48

DESCRIPTION AND OPERATION

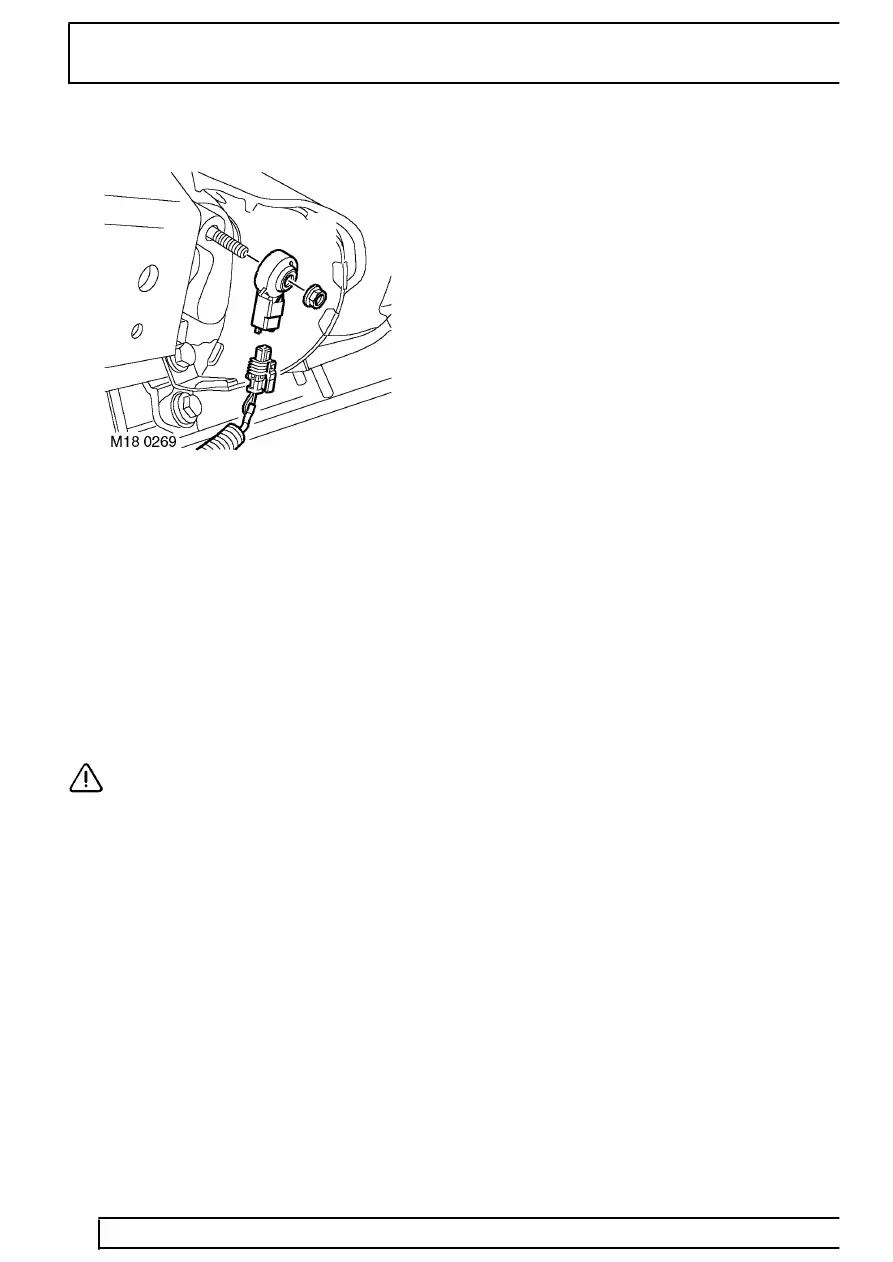

Knock Sensors (KS) - from 99MY

The ECM utilises active knock control, which serves to

prevent engine damage through pre-ignition or

detonation. Knock control is effective under all

operating conditions, enabling the engine to operate

without additional safety margins.

Two knock sensors are used, one mounted each side

of the cylinder block between the two centre cylinders

of each bank. Each sensor has two wires; a signal

wire providing input to the ECM and a ground

(screen). Each of the sensors monitor the ’knock’ from

four cylinders (Cylinder No’s: 1, 3, 5 & 7 and Cylinder

No’s: 2, 4, 6 & 8).

CAUTION: The connector and sensor

terminals are gold plated to provide good

conductivity and resistance to corrosion

and high temperatures. Be careful not to damage

terminals if probing with test equipment.

The knock sensors consist of piezo-ceramic crystals

that oscillate to create a voltage signal. During

pre-ignition, the frequency of crystal oscillation

increases which alters the signal output to the ECM.

The signal is processed by comparing it to signal

profiles contained in memory which indicate a

pre-ignition condition. If pre-ignition conditions are

evident, the ECM retards the ignition on that cylinder

for a number of cycles. The ignition timing gradually

reverts to its original setting.

The ignition system is calibrated to run on 95 RON

Premium fuel for optimum fuel economy and

performance characteristics. The system can also

function satisfactorily with 91 RON Regular fuel. If the

vehicle is refuelled with a lower grade of fuel some

audible detonation may be heard until the system

adaptions are complete for the new fuel grade.

If a knock sensor should fail, the following symptoms

may be observed:

•

Possible rough running

•

Reduction in engine performance

A knock sensor failure is likely to occur for the

following reasons:

•

Sensor open circuit

•

Short circuit to vehicle supply or ground

•

Faulty component

•

Loose sensor - incorrectly torqued

If knock control is disabled, a default "safe ignition

map" is used.

If a knock sensor should fail, the following fault codes

will be generated by the ECM diagnostics, which can

be retrieved by Testbook:

•

P0327 - (LH bank signal less than the threshold

value determined from the ECM model above

2200 rpm)

•

P0328 - (LH bank signal greater than the

threshold value determined from the ECM model

above 2200 rpm)

•

P0332 - (RH bank signal less than the threshold

value determined from the ECM model above

2200 rpm)

•

P0333 - (RH bank signal greater than the

threshold value determined from the ECM model

above 2200 rpm)

Noise induced on the battery supply line could be

misinterpreted as a knock signal and cause a

maximum knock fault. A maximum fault could be

caused by a short circuit to the battery supply or in the

case of extreme mechanical engine noise / piston

slap. A minimum fault is usually due to an open circuit.