Range Rover Classic

BORG WARNER

19

OVERHAUL

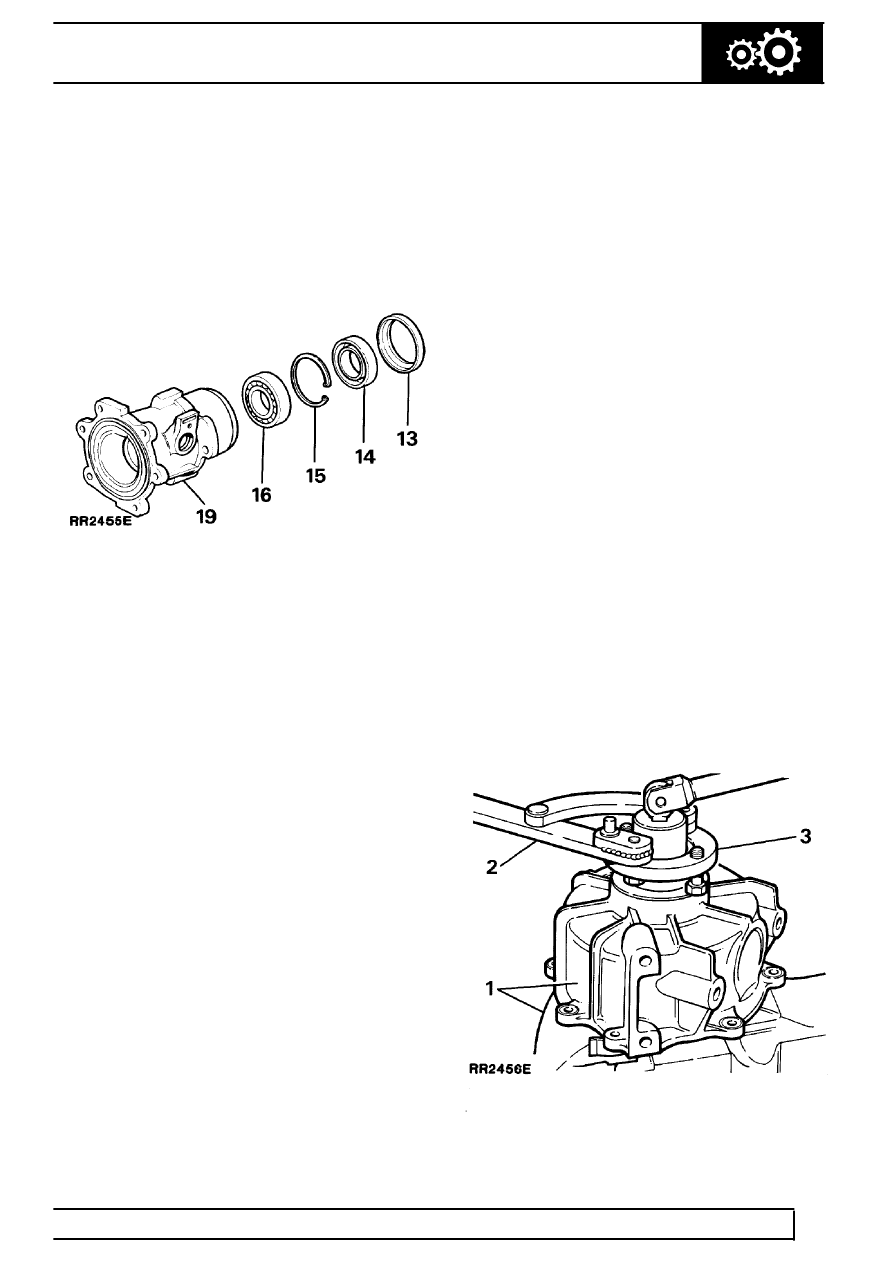

Rear output housing (continued)

13. Lever off the dust shield.

14. Prise the oil seal from the housing and discard

the seal.

15. Remove the circlip retaining the bearing.

16. Drive or press the bearing from the housing.

Discard the bearing.

17. Remove any previous sealant from the housing

joint face.

18. Thoroughly clean all components with a suitable

solvent.

19. Examine the housing for damage and wear.

Renew as necessary.

Rear output housing - Assemble

20. Drive or press a new bearing into the housing

until the bearing contacts the shoulder.

21. Fit the circlip.

22. Lubricate a new oil seal. Using oil seal replacer

18G1422 fit the seal, lip side leading until it

contacts the circlip.

23. Fit the dust shield.

24. Place the ball bearing in the indent on the output

shaft, fit the speedometer drive gear to the shaft,

secure together with the circlip.

25. Press or drive the output shaft into the housing

until the shoulder of the shaft contacts the

bearing.

26. Lubricate the oil seal bearing surface of the drive

flange and fit the flange followed by a new

rubber seal. Fit the steel washer and secure the

flange to the shaft using a new nut. Tighten to

the specified torque.

27. Lubricate a new speedometer sleeve oil seal,

press the seal into the top of the sleeve.

28. Fit a new ’O’ ring to the outside of the sleeve,

push the driven gear spindle into the sleeve.

29. Lubricate the ’O’ ring and push the sleeve and

gear assembly into the housing. It may be

necessary to rotate the output shaft to ensure

that the driven gear engages with the drive gear

on the shaft.

30. Apply Dow Corning 732 or a suitable equivalent

silicone sealant to the rear output housing joint

face on the main casing. Evenly spread the

sealant on the face to ensure a good seal.

31. Fit the housing to the main casing and secure

with the six bolts tightened to the specified

torque.

Front output housing

- Dismantle and Inspection

Service tools:

18G1422 - Oil seal replacer.

18G1205 - Adjustable flange holding wrench

1. Support the viscous unit and front output

housing in a vice fitted with soft jaws gripping on

the two flats of the viscous unit.

2. Using service tool 18G1205 to restrain the drive

flange, release and remove the nyloc nut and

plain washer securing the drive flange to the

output shaft, withdraw the rubber seal. Discard

the nut and seal.

3. Remove the drive flange from the viscous unit.

Examine the flange for damage or wear

particularly the seal running surface, if the

surface is corroded or a groove has been worn

by the previous seal discard the flange.