Range Rover Classic

CHASSIS AND BODY

73

REPAIR

ADD: 09/95

7. Remove RH ’A’ post finisher.

8. Remove header finisher.

9. Apply masking tape to protect paint finish around

glass.

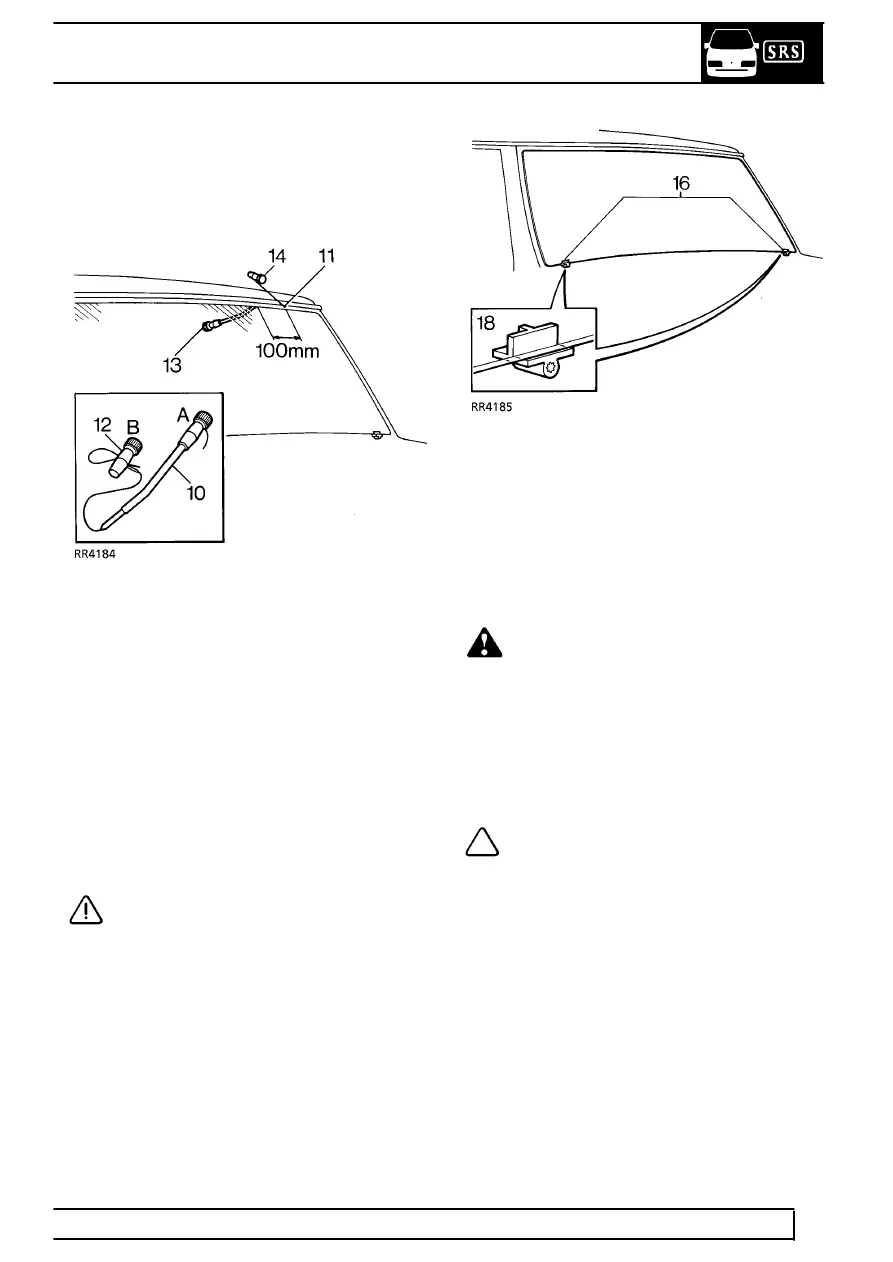

10. Prepare cutting wire in handle ’A’. Bend end of

wire to handle and tape over end.

11. Force cutting wire through sealer from inside and

100mm from a top corner. Use a needle if

necessary to make a pilot hole.

12. Attach handle ’B’. Allow 200mm of wire between

handles, tape over end of wire.

13. With an assistant on the inside: Wedge the

tube of the handle ’A’ between glass and body

flange 100mm ahead of hole in sealer.

14. From the outside: Carefully cut sealer from

flange using a straight pull away from the glass.

Continue in 100mm steps around the glass, use

a sawing action at the corners.

CAUTION: Along the bottom edge, great

care must be taken to cut up to the 2

supports, positions indicated on the

obscuration band (See item 18).

15. Remove handle ’B’, withdraw the cutting wire

and insert it through the sealer between the

supports. Refit handle ’B’.

16. Cut through sealer between the supports.

If heated front screen: Cut through the 2 wires

each side of the supports. Tape cut wires and

panels to prevent damage to bodywork when

screen is removed.

17. Attach suction cups to glass and lift glass from

body flange, cut sealer free around supports as

necessary.

WARNING: If glass has splintered: Protect

eyes and operate demister blower at

maximum speed to remove any glass from

ducts. Use a vacuum cleaner to remove glass

particles from inside the vehicle.

Refit

18. Check condition of supports, renew if necessary.

Locating studs must be at right angle to flange.

NOTE: The supports were fitted to early

vehicles and now replaced with nylon

sheaths.

19. Carefully cut back old sealant around body

flange to obtain a smooth surface 2mm thick. DO

NOT cut down to flange.

20. If refitting original glass: It must be free from

chips or cracks. Cut back old sealant around

glass to obtain a smooth surface 2mm thick. DO

NOT cut down to glass surface.