Engine Overhaul Manual v8 40 46: Description and Operation

ENGINE

DESCRIPTION AND OPERATION

7

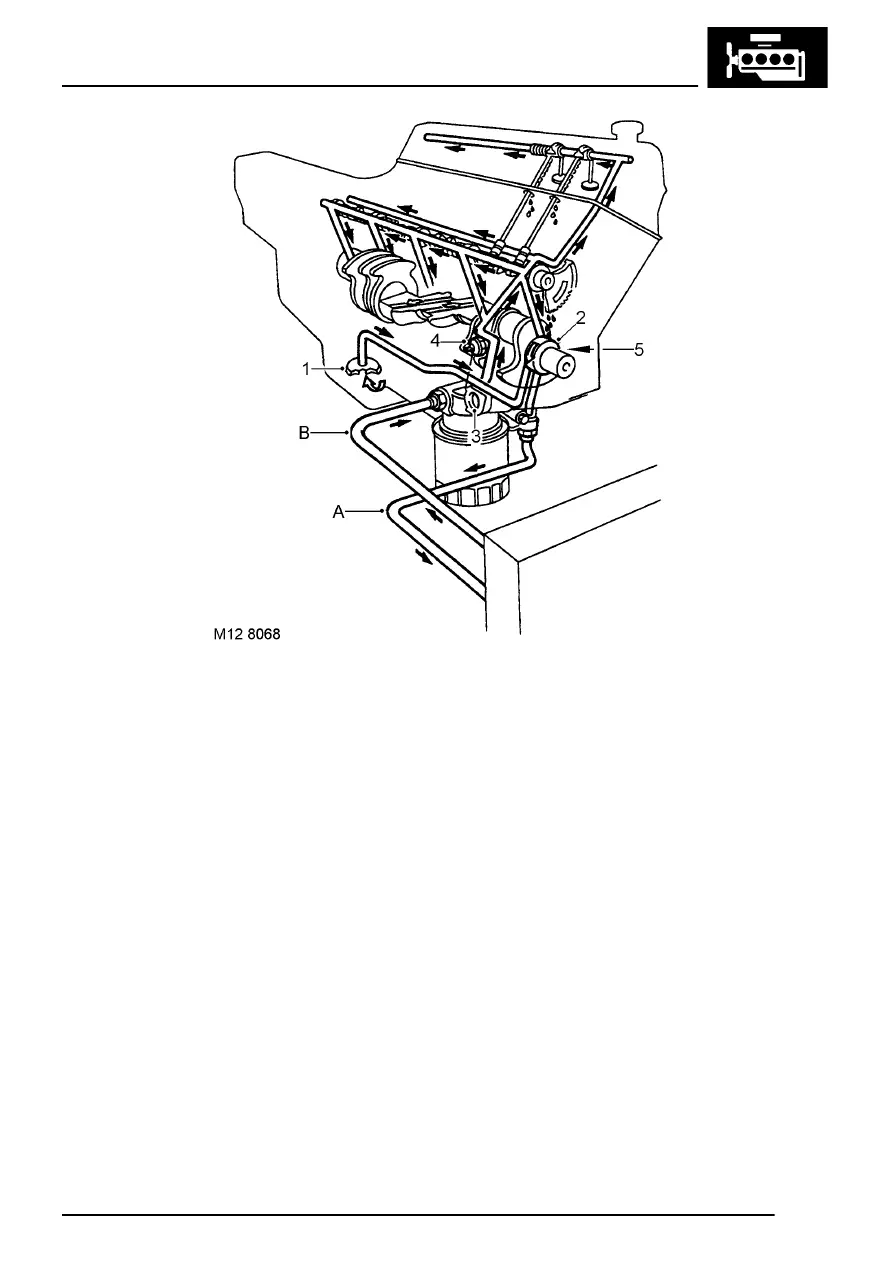

1. Oil strainer

2. Oil pump

3. Oil pressure by-pass valve

4. Oil pressure switch

5. Oil pressure relief valve - if fitted

A Oil to cooler - if fitted

B Oil from cooler - if fitted

Lubrication

The full flow lubrication system uses a gear type oil

pump driven from the crankshaft. The assembly is

integral with the timing cover which also carries the

full flow oil filter, oil pressure switch, oil pressure

by-pass valve and oil pressure relief valve - if fitted.

Oil is drawn from the pressed steel sump through a

strainer and into the oil pump, excess pressure

being relieved by the pressure relief valve. The oil

pressure warning light switch is screwed into the

timing cover and registers the oil pressure in the

main oil gallery on the outflow side of the filter.

Pressurised oil passes through an oil cooler - if fitted

mounted in front of the radiator to the full flow oil

filter. The oil then passes through internal drillings to

the crankshaft where it is directed to each main

bearing and to the big end bearings via numbers 1,

3 and 5 main bearings.

An internal drilling in the cylinder block directs oil to

the camshaft where it passes through further internal

drillings to the hydraulic tappets, camshaft journals

and rocker shaft. Lubrication to the thrust side of the

cylinders is either by oil grooves machined in each

connecting rod big end joint face or by splash.