Engine Overhaul Manual: Description and Operation - How It Works

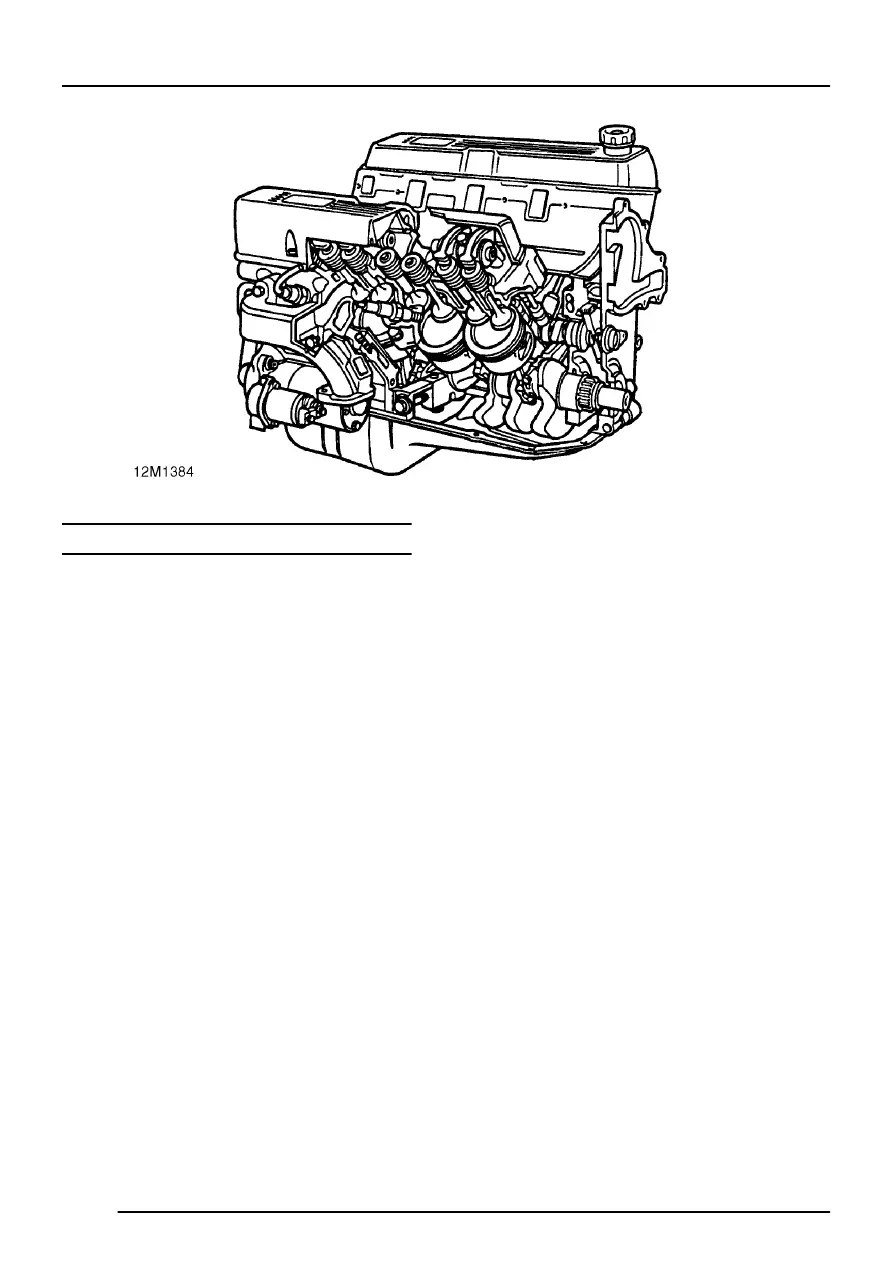

ENGINE

6

DESCRIPTION AND OPERATION

OPERATION

The V8 engine is an eight cylinder, water cooled unit

comprising cast aluminium cylinder block and

cylinder heads.

The cast iron cylinder liners are shrink fitted and

located on stops in the cylinder block. The banks of

cylinders are at 90

°

to each other. The crankshaft is

carried in five main bearings, end-float being

controlled by the thrust faces of the upper centre

main bearing shell.

The centrally located camshaft is driven by the

crankshaft via a chain. The valves are operated by

rockers, pushrods and hydraulic tappets. Exhaust

valves used on later engines are of the ’carbon

break’ type which incorporate a machined undercut

at the combustion chamber end of the valve. The

design prevents carbon build-up on the valve stem

which could lead to valves sticking. These valves

are interchangeable with valves fitted to early

engines provided that the latest valve guides which

are 5 mm (0.2 in) than those fitted to early engines

are also fitted.

Each of the aluminium alloy pistons has two

compression rings and an oil control ring. The

pistons are secured to the connecting rods by

semi-floating gudgeon pins. The gudgeon pin is

offset 0.5 mm (0.02 in), identified by an arrow mark

on the piston crown, which must always point to the

front of the engine. Plain, big-end bearing shells are

fitted to each connecting rod.