Engine Overhaul Manual v8 4.0 4.6

ENGINE

44

OVERHAUL

Drive plate and ring gear assembly - refit - Drive

plates with unshimmed hub aligner and later

engines fitted with modified ’one-piece’ starter

ring gear

NOTE: It is not necessary to check setting

height on drive plates fitted to the above

engines. On early engines, balance

weights are on engine side of drive plate;

replacement drive plates will have balance

weights on torque converter side.

Early engines with unshimmed hub aligner

1. Ensure bolt holes in crankshaft are clean and

dry. Fit hub aligner, fit Allen bolts and tighten to

78 Nm (58 lbf.ft).

2. Fit ring gear assembly, spacer, drive plate and

clamp ring ensuring that reference marks are

aligned.

CAUTION: If a new drive plate is being

fitted, paint mark must face towards

torque converter, ensure holes in plate are

aligned with clearance holes in ring gear.

3. Fit clamp ring bolts and tighten to 45 Nm (33

lbf.ft).

Later engines with modified ’one-piece’ starter

ring gear

1. Ensure bolt holes in crankshaft are clean and

dry

2. Fit starter ring gear, fit Allen bolts and tighten

to 85 Nm (63 lbf.ft).

3. Fit drive plate and clamp ring, fit bolts and

tighten to 45 Nm (33 lbf.ft.

CRANKSHAFT, MAIN AND BIG-END BEARINGS

Big-end bearings - remove

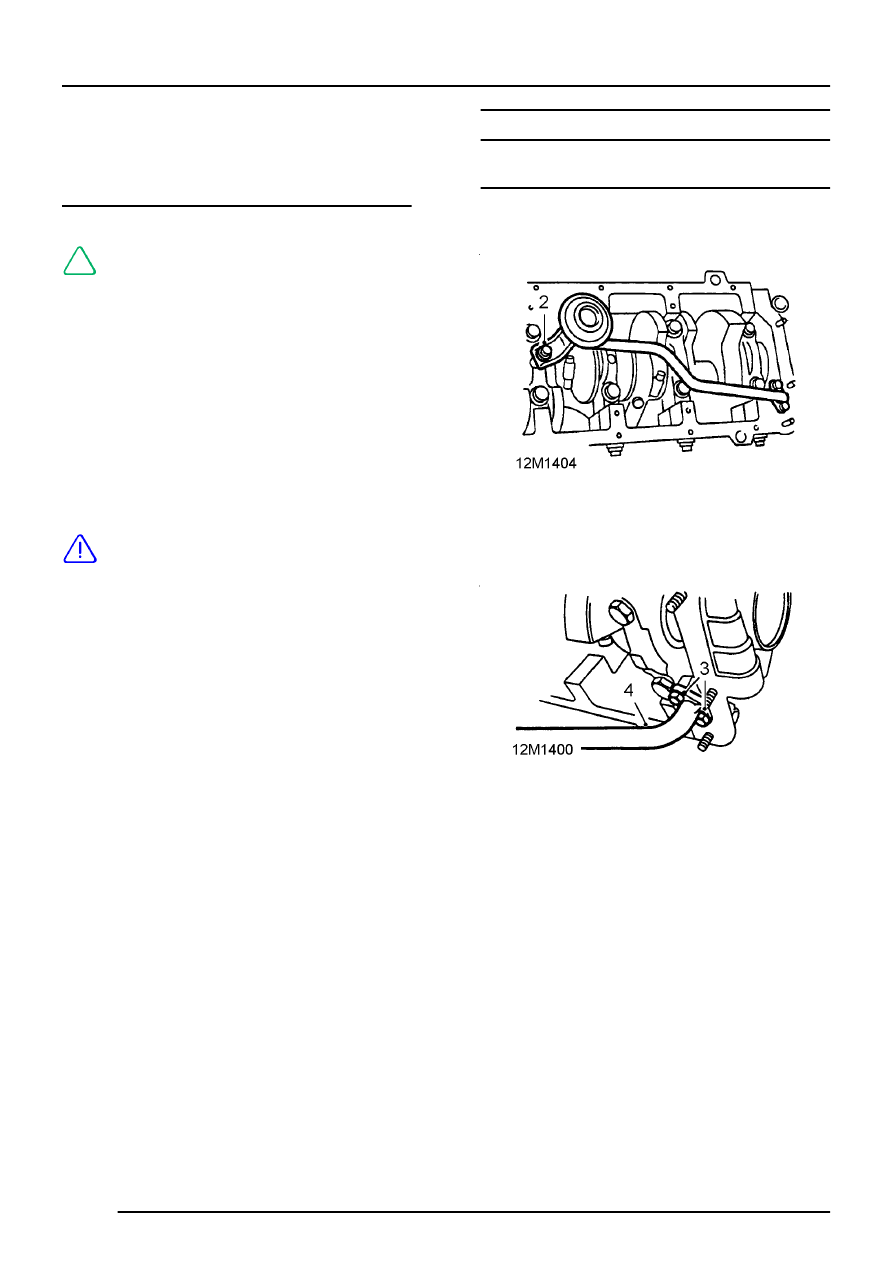

1. Remove timing chain and gears.

2. Remove nut and washers securing oil pick-up

pipe to stud.

3. Remove 2 bolts securing oil pick-up pipe to oil

pump cover, withdraw pipe from cover; remove

and discard ’O’ ring.

4. Remove oil pick-up pipe, recover spacer from

stud.

5. Suitably identify bearing caps to their

respective connecting rods.