Engine Overhaul Manual v8 4.0 4.6

ENGINE

OVERHAUL

39

Flywheel and starter ring gear - inspection

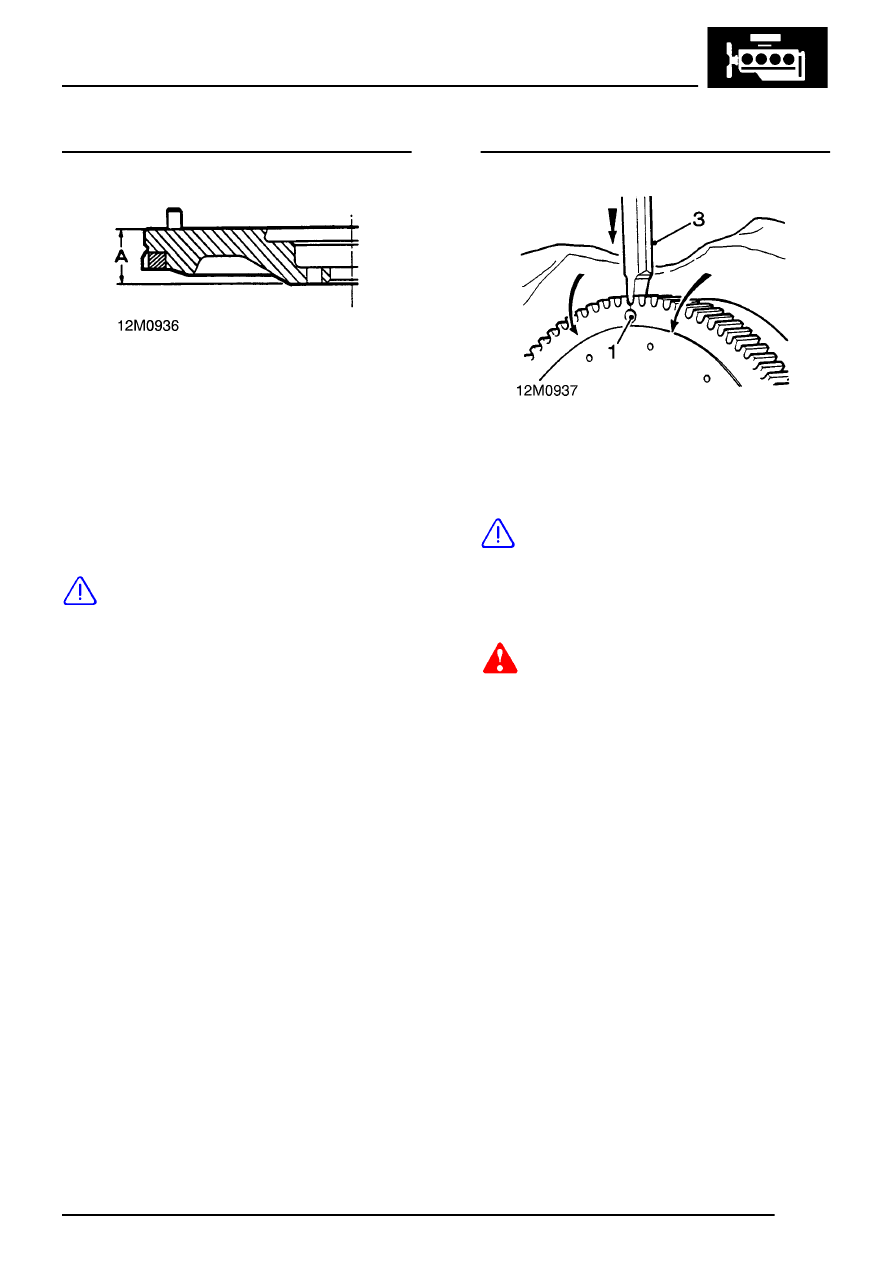

1. Inspect flywheel face for cracks, scores and

overheating. The flywheel can be refaced on

the clutch face providing thickness does not go

below minimum.

Flywheel minimum thickness A = 40.45 mm

(1.6 in)

2. Inspect starter ring gear for worn, chipped and

broken teeth.

CAUTION: Do not attempt to remove

reluctor ring.

3. Renew starter ring gear if necessary.

Starter ring gear - renew

1. Drill a 6 mm (0.250 in) diameter hole at root of

2 teeth.

CAUTION: Do not allow drill to enter

flywheel.

2. Secure flywheel in soft jawed vice.

3. Split ring gear using a cold chisel.

WARNING: Wear safety goggles and take

precautions against flying fragments when

splitting ring gear.

4. Remove flywheel from vice, remove old ring

gear, and place flywheel, clutch side down, on

a flat surface.