Engine Overhaul Manual v8 4.0 4.6

ENGINE

OVERHAUL

9

7. Check valve stem to guide clearance D using

the following procedures:

8. Insert each valve into its respective guide.

9. Extend valve head approximately 13 mm (0.6

in) out of valve seat and position a suitable dial

test indicator to rear of valve head.

10. Move valve towards front of cylinder head and

zero dial test indicator gauge ensuring that

stylus of gauge remains in contact with valve

head.

11. Move valve towards rear of cylinder head and

record gauge reading to give valve stem to

guide clearance:

Inlet valves - Early and later engines = 0.025 to

0.066 mm (0.001 to 0.002 in)

Exhaust valves:

Standard and carbon break exhaust valves

fitted to early engines = 0.038 to 0.078 mm

(0.0015 to 0.003 in)

Modified carbon break exhaust valves fitted to

later engines = 0.048 to 0.088 mm (0.0019 to

0.0035 in)

12. Repeat above procedures for each valve in

turn.

13. Renew valves, guides and valve seat inserts

as necessary.

CAUTION: If modified valves and guides

are to be fitted, they must be replaced in

engine sets.

14. Check condition of valve springs:

Free length = 48.30 mm (1.90 in)

Fitted length = 40.40 mm (1.60 in)

Load - valve closed = 339

±

10 N (76

±

2 lbf)

Load - valve open = 736

±

10 N (165

±

2 lbf)

NOTE: Valve springs must be replaced as

a complete set.

Valve guides - renew

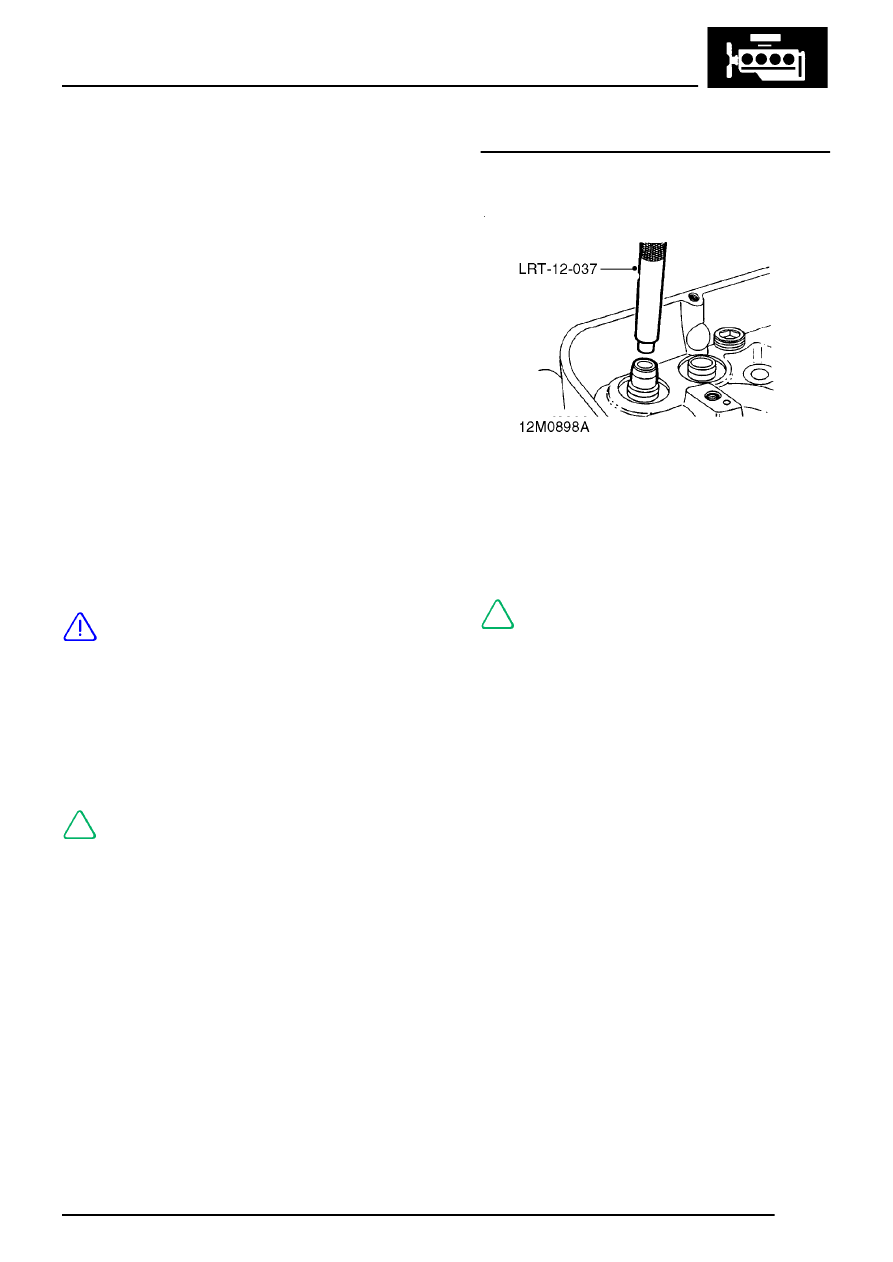

1. Using valve guide remover, LRT-12-037 press

valve guide out into combustion face side of

cylinder head.

NOTE: Service valve guides are 0.025 mm

(0.001 in) oversize on outside diameter to

ensure interference fit.

2. Lubricate new valve guide with engine oil,

position guide with tapered portion leading to

valve spring side of cylinder head.